Mr Ed

Established Member

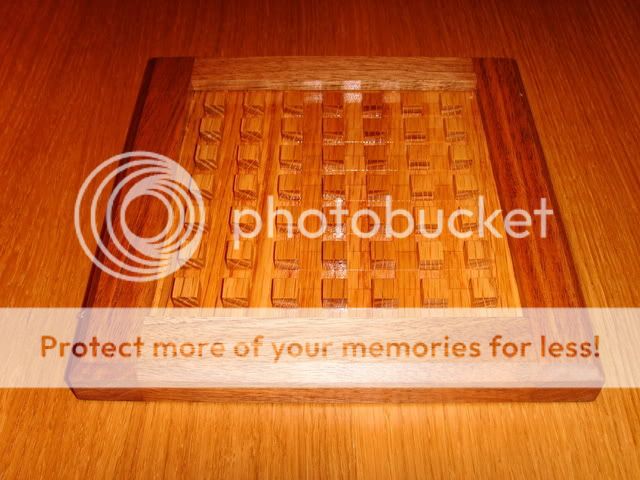

For what I reckon must be several years now I've been promising to make some new trivets (pot stands) for the kitchen, to replace some that have broken. These took about 30 minutes to make and have generated high levels of kudos - I recommend it to you all.

I don't think much of an explanation of how they are made is needed. They are 200mm square, made of oak using the router table.

The only trick is to set the cutter to just slightly more than half the thickness to get clean transitions between the verticals and horizontals.

Happy routing.

Cheers, Ed

I don't think much of an explanation of how they are made is needed. They are 200mm square, made of oak using the router table.

The only trick is to set the cutter to just slightly more than half the thickness to get clean transitions between the verticals and horizontals.

Happy routing.

Cheers, Ed