RogerS

Established Member

Morning, chaps. A little problem to get those grey cells going this morning...

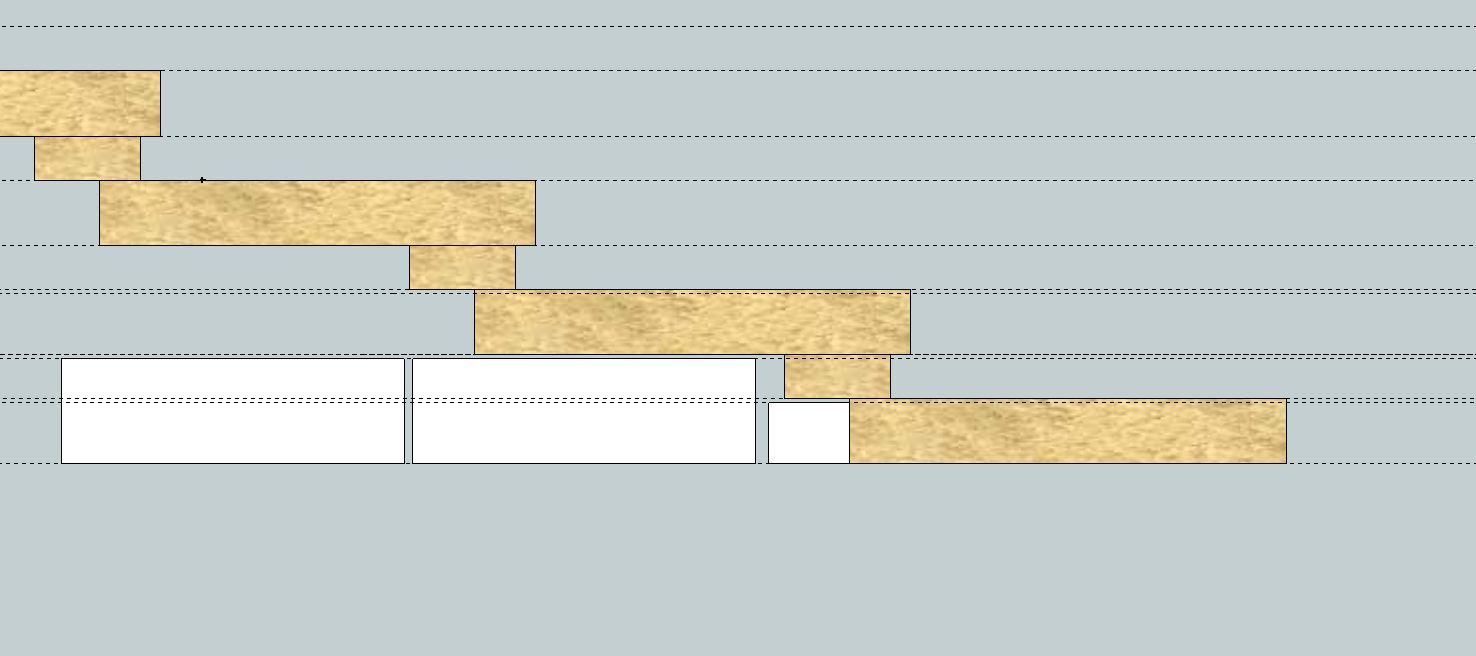

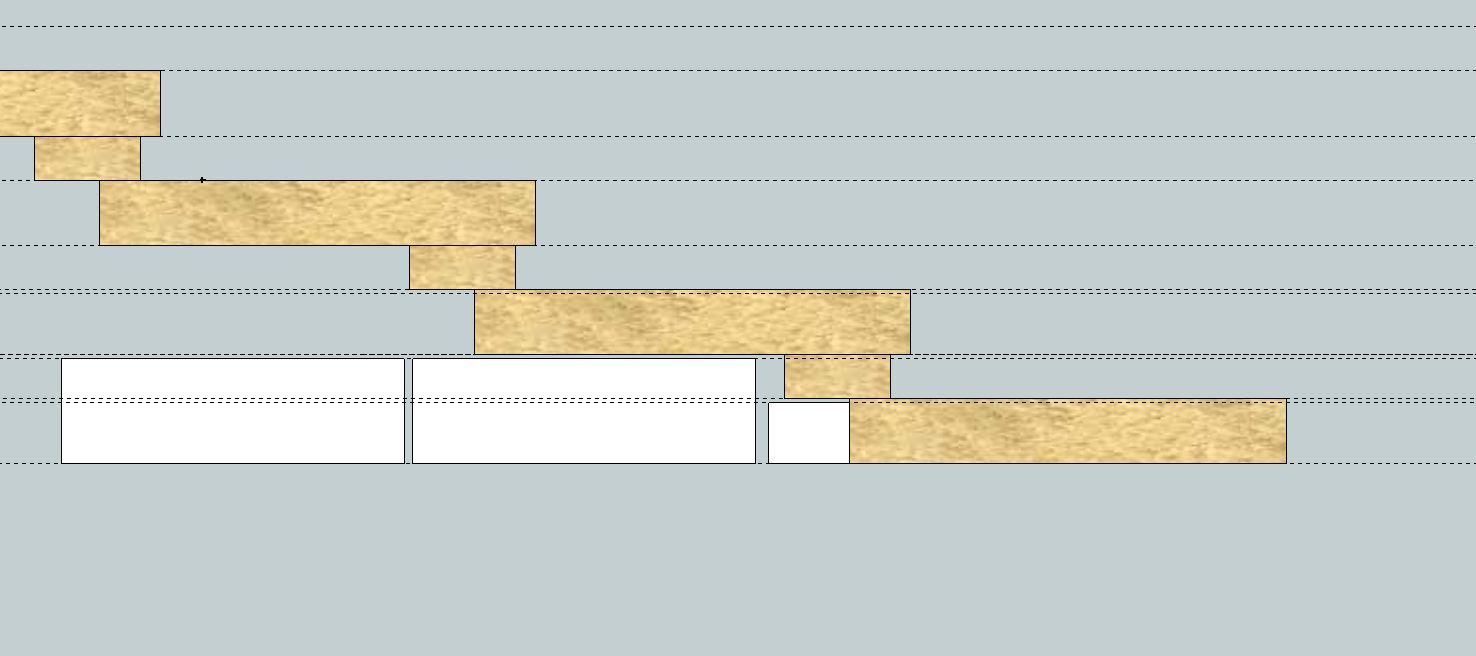

Builder's coming this morning to lay some sandstone steps. A cross-section here.

The sandstone steps each weigh 150 kg and I want to have them end up sitting directly on top of each other as shown. So he needs to make blockwork underneath to support them...again, roughly as shown. Thing is, the accuracy of each tread height has to be mm perfect which, thinking about the roughness of the blocks is not possible. So I'm thinking about possibly setting each blockwork level (5mm ?) below the finish height then when we come to lay the treads, set plastic spacers on top of the blockwork support for each tread to provide a level surface for the tread and then laying a thin layer of 'what?' to sit the tread on.

Or I was wondering about making two templates out of ply to give him levels to work to - one at each side...but you know what builders are like ....they'll probably get knocked out of whack and so upset the levels.

Any suggestions ?

TIA

Builder's coming this morning to lay some sandstone steps. A cross-section here.

The sandstone steps each weigh 150 kg and I want to have them end up sitting directly on top of each other as shown. So he needs to make blockwork underneath to support them...again, roughly as shown. Thing is, the accuracy of each tread height has to be mm perfect which, thinking about the roughness of the blocks is not possible. So I'm thinking about possibly setting each blockwork level (5mm ?) below the finish height then when we come to lay the treads, set plastic spacers on top of the blockwork support for each tread to provide a level surface for the tread and then laying a thin layer of 'what?' to sit the tread on.

Or I was wondering about making two templates out of ply to give him levels to work to - one at each side...but you know what builders are like ....they'll probably get knocked out of whack and so upset the levels.

Any suggestions ?

TIA