I've had endless problems with curling and poor adhesion, which has led me deep into the world of auto bed levelling where getting your hands dirty with a bit of GCode is a necessity. If you've managed to avoid that then you're a luckier man than me.I've printed a fair bit and never even looked at any gcode.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Dust hose adaptor problems - be gone!

- Thread starter Farmer Giles

- Start date

Help Support UKworkshop.co.uk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Farmer Giles

The biggest tool in the box

I've added a raspberry pi for octoprint and time lapse photography, a new main board, BL touch for auto bed levelling and swapped out the hot end and the extruder for different ones.

None of them have been essential, I would say incremental improvements in quality, ability or convenience but some are marginal. But I enjoy doing it. It has meant getting into a bit of gcode and a lot of Marlin compilation, and lots of tinkering. I'm just wrestling with a filament run/out sensor now, its not behaving itself, but I have a kitchen to build and machinery to renovate so that may take a while longer.

With PLA, I was having warping issues, where I got the best improvement from was reducing bed temp to 45c and using some bed glue.

None of them have been essential, I would say incremental improvements in quality, ability or convenience but some are marginal. But I enjoy doing it. It has meant getting into a bit of gcode and a lot of Marlin compilation, and lots of tinkering. I'm just wrestling with a filament run/out sensor now, its not behaving itself, but I have a kitchen to build and machinery to renovate so that may take a while longer.

With PLA, I was having warping issues, where I got the best improvement from was reducing bed temp to 45c and using some bed glue.

Ollie78

Established Member

I have an Ender 3, it is good but I had terrible trouble with it gumming up the nozzle and blobbing.

Spoke to a friend with the same machine and some others he said that it is VERY important that you get good quality filament (he uses Prusa only now after trying many) . The issue comes from poor quality control when its extruded and any small variation in filament thickness can cause the blobbing.

I was using Amazon basic. Ordereing prusa stuff and will try again soon.

Ollie

Spoke to a friend with the same machine and some others he said that it is VERY important that you get good quality filament (he uses Prusa only now after trying many) . The issue comes from poor quality control when its extruded and any small variation in filament thickness can cause the blobbing.

I was using Amazon basic. Ordereing prusa stuff and will try again soon.

Ollie

Farmer Giles

The biggest tool in the box

I had some issues with filament, turns out on some of the Ender 3 printers, the extruder had too strong a spring meaning the filament was being squashed so it was wider in one direction, beyond the tolerances recommended by the tubing manufacturer. Loads of youtube videos show you how to increase extruder spring pressure to improve filament feeding, I wonder how many have followed these instructions only to make it worse.

I do notice differences between PLA makes, but not enough to stop me using it. Main differences is finding the sweet spot in terms of bed and nozzle temp for that PLA. I always keep my PLA in a sealed bag after use, its hygroscopic and water changes its characteristics, I haven't resorted to sticking it in the over on a low heat yet....

I do notice differences between PLA makes, but not enough to stop me using it. Main differences is finding the sweet spot in terms of bed and nozzle temp for that PLA. I always keep my PLA in a sealed bag after use, its hygroscopic and water changes its characteristics, I haven't resorted to sticking it in the over on a low heat yet....

DBT85

Established Member

I have been exceedingly fortunate by the sound of things. I just manually bed level with a post it and have never had any issues with blobbing or stringing or adhesion. It's white AMZ3D PLA I got from Amazon that just stays on the machine when not in use.

The only mods I've done is to print parts for the machine to cover the cables, add trays etc. As I said, not even got around to fitting the dampers yet! I just keep the bed (stock magnetic pad) at 60 and hot end at 200.

I thought I'd get into the bed levelling, anew board, a new bed, teflon feeder tube and all sorts but frankly it just hasn't felt necessary.

The only issue I've had was my hose adapter printing out 0.3mm narrower than designed. I printed a test cube and it was something like 19.97, 20.03, 19.96 mm all around, so I just increased my models by the 0.3mm.

Eventually I may use it to make the parts for a cnc.

Literaly the first thing i printed

An adapter for my brothers hot tub.

The only mods I've done is to print parts for the machine to cover the cables, add trays etc. As I said, not even got around to fitting the dampers yet! I just keep the bed (stock magnetic pad) at 60 and hot end at 200.

I thought I'd get into the bed levelling, anew board, a new bed, teflon feeder tube and all sorts but frankly it just hasn't felt necessary.

The only issue I've had was my hose adapter printing out 0.3mm narrower than designed. I printed a test cube and it was something like 19.97, 20.03, 19.96 mm all around, so I just increased my models by the 0.3mm.

Eventually I may use it to make the parts for a cnc.

Literaly the first thing i printed

An adapter for my brothers hot tub.

Last edited:

rwillett

Established Member

I have an Ender 3 Pro, the main difference between the Pro and the non-pro is the use of a magnetic bed and a magnetic sheet that goes over it. The sheet provides good adhesion and so I have never used any of the tips and tricks with tape and hair spray. There are different magentic covers that all look the same from Amazon. Some are too adhesive and I have ended up wrecking two as the models stuck so hard to the sheet, it pulled the cover off.

The difference in 32 bit boards is negligable. The later one is quieter than the earlier one, but unless you are updating the firmware (which isn't that difficult), I wouldn't be too bothered which one to get. I've had both and its made no difference to me.

The key things to remember about the Ender 3 and 3d printing is to get all the axis's at right angles, use a decent steel ruler and a square, and getting the bed levelling correct. As a previous poster has stated, they use a post it note to check the thickness. Heat the bed and the nozzle to the right temperature (you do this as the metal expands), slip a thin piece of paper and adjust the four screws underneath the bed until the paper is just catching on the nozzle. However as you get one part right, it puts the others out of alignment, so you need to go round it a few times. My Ender 3 bed is slightly concave in the middle, (0.1mm?), but thats enough to stop the filament sticking in some cases. This sounds a lot more difficult than it is, and after a few attempts it's second nature.

I do have a BLTouch but the firmware that comes with the Ender 3 Pro (on my version) doesn't support it, so I had to build my own firmware. I build software for a living so this holds no fear, but I could not get the BLTouch V3 to work with Marlin V2.x.x.x. I probably spent six weeks and compiled 50-60 versions and had a lot of discussions with serious developers. We put it down to the version of BLTouch and the version of the motherboard. However other people have stated they got it working first time, so YMMV.

Decent PLA+ is a must. I only buy eSun as I have got that working very well indeed AND it comes in a clear reel so I can actually see how much filament I have left. I have used other filament as well with few problems to be fair. I print at 205C for the nozzle and 45 for the bed and that works for me.

I also use Octoprint on a raspberry pi 3 which is connected via wifi. This basically acts as a print server and web based control model. Can't recommend Octoprint highly enough. I even subscribe a few pounds a month to the developer.

I brought my Ender 3 Pro to build a CNC machine. You can see it here (New build in Clapham, North Yorkshire, UK).

Would I buy an Ender 3 again? No, I'd buy two The issue you will find is that things take a long time to print, the CNC machine took over 250 elapsed hours to print, so I ran the printer non stop (as much as I could) for nearly a month. I still think I may buy a second one to do things in parallel. A more expensive printer won't necessarily be much faster BUT might print larger objects. Mine does circa 200x200x200 and thats fine for me. Anything bigger than that is going to take days to print.

The issue you will find is that things take a long time to print, the CNC machine took over 250 elapsed hours to print, so I ran the printer non stop (as much as I could) for nearly a month. I still think I may buy a second one to do things in parallel. A more expensive printer won't necessarily be much faster BUT might print larger objects. Mine does circa 200x200x200 and thats fine for me. Anything bigger than that is going to take days to print.

I use Fusion 360 (the free edition). As of Oct 1st Autodesk removed some features from the free edition but it's not affected me at all. I don't use the machine part of F360 but simply export STL models to my Mac and use PrusaSlicer to slice and dice the model and then send it to the Ender 3 via Octoprint. Quick and easy and no messing around with SD cards.

I had no idea about F360 until probably June this year and have now graduated to quite complex models. I am not a designer (though you can probably guess that). here's the modular dust shoe I'm designing for my CNC. It's modular as it needs to adapt to different heights quickly and easily.

If you want a simple dust hose adaptor, hand draw a simple sketch showing the interior and exterior dimensions, anything that connects to anything else MUST be as accurate as you can make it and sent it to me. I'll knock it up in F360 and print it out for free (assuming its not 200x200x200mm) and post it to you.

I made a number of dust connectors for my Henry vac and dust cyclone.

Here's a screw threaded adaptor

and a rotating hose clamp for a Henry hose

Most of these are pretty simple, but the important things is to get the dimensions right.

The offer to print is there, it will be in Fireengine red as thats the filament on the Ender 3 at the moment.

Rob

The difference in 32 bit boards is negligable. The later one is quieter than the earlier one, but unless you are updating the firmware (which isn't that difficult), I wouldn't be too bothered which one to get. I've had both and its made no difference to me.

The key things to remember about the Ender 3 and 3d printing is to get all the axis's at right angles, use a decent steel ruler and a square, and getting the bed levelling correct. As a previous poster has stated, they use a post it note to check the thickness. Heat the bed and the nozzle to the right temperature (you do this as the metal expands), slip a thin piece of paper and adjust the four screws underneath the bed until the paper is just catching on the nozzle. However as you get one part right, it puts the others out of alignment, so you need to go round it a few times. My Ender 3 bed is slightly concave in the middle, (0.1mm?), but thats enough to stop the filament sticking in some cases. This sounds a lot more difficult than it is, and after a few attempts it's second nature.

I do have a BLTouch but the firmware that comes with the Ender 3 Pro (on my version) doesn't support it, so I had to build my own firmware. I build software for a living so this holds no fear, but I could not get the BLTouch V3 to work with Marlin V2.x.x.x. I probably spent six weeks and compiled 50-60 versions and had a lot of discussions with serious developers. We put it down to the version of BLTouch and the version of the motherboard. However other people have stated they got it working first time, so YMMV.

Decent PLA+ is a must. I only buy eSun as I have got that working very well indeed AND it comes in a clear reel so I can actually see how much filament I have left. I have used other filament as well with few problems to be fair. I print at 205C for the nozzle and 45 for the bed and that works for me.

I also use Octoprint on a raspberry pi 3 which is connected via wifi. This basically acts as a print server and web based control model. Can't recommend Octoprint highly enough. I even subscribe a few pounds a month to the developer.

I brought my Ender 3 Pro to build a CNC machine. You can see it here (New build in Clapham, North Yorkshire, UK).

Would I buy an Ender 3 again? No, I'd buy two

I use Fusion 360 (the free edition). As of Oct 1st Autodesk removed some features from the free edition but it's not affected me at all. I don't use the machine part of F360 but simply export STL models to my Mac and use PrusaSlicer to slice and dice the model and then send it to the Ender 3 via Octoprint. Quick and easy and no messing around with SD cards.

I had no idea about F360 until probably June this year and have now graduated to quite complex models. I am not a designer (though you can probably guess that). here's the modular dust shoe I'm designing for my CNC. It's modular as it needs to adapt to different heights quickly and easily.

If you want a simple dust hose adaptor, hand draw a simple sketch showing the interior and exterior dimensions, anything that connects to anything else MUST be as accurate as you can make it and sent it to me. I'll knock it up in F360 and print it out for free (assuming its not 200x200x200mm) and post it to you.

I made a number of dust connectors for my Henry vac and dust cyclone.

Here's a screw threaded adaptor

and a rotating hose clamp for a Henry hose

Most of these are pretty simple, but the important things is to get the dimensions right.

The offer to print is there, it will be in Fireengine red as thats the filament on the Ender 3 at the moment.

Rob

£17.99 (£1.80 / count)

£27.44 (£2.74 / count)

3M 8822 Disposable-fine dust mask FFP2 (10-pack)

Amazon.co.uk

£12.50 (£1.25 / count)

£14.45 (£1.44 / count)

JSP M632 FFP3moulded Disposable Dustmask (Box of 10) One Size suitable for Construction, DIY, Industrial, Sanding, dust protection 99 Percent particle filtration Conforms and Complies to EN 149

Amazon.co.uk

£19.46 (£3.89 / count)

£19.99 (£4.00 / count)

Stealth Lite Pro FFP3 Face Masks UK Certified Dust Mask. 99.99% particle filtration, air filter reusable face mask. FFP3 Mask -7 day use per Construction, Woodworking, DIY and Welding Mask

Amazon.co.uk

£26.99 (£1.35 / count)

VEVOX® FFP2 Dust Mask - Set of 20 - Valved Face Masks - Respirator - Protection e.g. for Construction, Building Work, Sanding, Woodworking, Fine Dusts, Aersoles or Particles

SLSK Ventures GmbH (UK)

Farmer Giles

The biggest tool in the box

Nice one Rob, I'm jealous of your CAD ability.

I use the BigTreeTech v2 32 bit board, I had a few issues compiling the code for the BLtouch as I am using the Marlin Bugfix branch rather than BigTreeTech's version of Marlin but didn't take too long. The other problem was the wiring for the BLTouch, the colours are not standard depending on which one you bought. I had to put a cross in the cable with jumpers to get it to work.

Here's what I sussed in terms of colour codes for the different sources of BL touch cabling.

The main benefit of the board was the lack of stepper motor noise, its a vast improvement. The printer is in the same room as my work office so couldn't use it when I was on conference calls before, now the PSU fan is the loudest part but I can live with that, for now. I have a bigger quieter fan to fit but that will have to wait. The proper bootloader and additional memory are icing on the cake.

Cheers

Andy

I use the BigTreeTech v2 32 bit board, I had a few issues compiling the code for the BLtouch as I am using the Marlin Bugfix branch rather than BigTreeTech's version of Marlin but didn't take too long. The other problem was the wiring for the BLTouch, the colours are not standard depending on which one you bought. I had to put a cross in the cable with jumpers to get it to work.

Here's what I sussed in terms of colour codes for the different sources of BL touch cabling.

| BTT SKR Mini E3 socket | BTT SKR Mini E3 label | AntClabs BL touch wiring | BTT Bltouch wire harness colours | Creality BLTouch for v1 mainboard wire harness colours |

| Z-probe | PC14 | | | |

| | GND | | | |

| | PA1 | Orange or yellow | Green | Yellow |

| | +5v | Red | Yellow | Red |

| | GND | Brown | Orange | Blue |

| Z-stop | GND | Black | Blue | Black |

| | PC2 | White | Black | White |

The main benefit of the board was the lack of stepper motor noise, its a vast improvement. The printer is in the same room as my work office so couldn't use it when I was on conference calls before, now the PSU fan is the loudest part but I can live with that, for now. I have a bigger quieter fan to fit but that will have to wait. The proper bootloader and additional memory are icing on the cake.

Cheers

Andy

Last edited:

rwillett

Established Member

The F360 stuff just comes along. I struggled to draw a simple square and extrude it to a cube. You just keep trying. F360 has a lot of capabilities but sometimes there are quirks like cutting, copying and pasting. I just keep looking things up and working through it. The dust show system is on V41 of which I have printed around 10 of them. My issue is that my CNC machine is optimised to cut 60mm foam, so it has high legs. Normally this is a no-no and you want the legs to be as short as possible as the leverage (or something) goes up by the square of the height. Foam is easy to cut so this isn't an issue. However I also want to engrave wood and do some cutting in which case I need to lower the router or lift up the spoil board. I then need to adjust the height of the dust show as it should be a few mm (at most) above the cutting surface. This is why it's modular. I needed to learn F360 to get my CNC built. I also had to learn about 3d printing along the way. I don't regret buying the Ender 3 for a second. Its a great workhorse. The only changes I've made are a new extrusion spring and arm, a new extruder (as I messed up the old one), new tubes as I blew the old ones out (probably through running too hot for PETG), a new control board as I dropped a metal ruler on the old one by mistake whilst it was powered up (doh) and new magnetic print mats. Mmm... thats quite a lot now I think about it, but most of the stuff is cheap.

We think the problem with my BLtouch is a 5v vs 3.3v issue and the MB. I wasn't going to cut any capacitors on any MB to test it to prove or disprove this.

My Ender 3 sits in the same home office, but I'm kind of used to the noise as I have a fileserver and an ESXI server and a large printer.

Anyway, we're going off topic. Happy to print an adaptor and can recommend the Ender 3 Pro (regardless of motherboard version).

Rob

We think the problem with my BLtouch is a 5v vs 3.3v issue and the MB. I wasn't going to cut any capacitors on any MB to test it to prove or disprove this.

My Ender 3 sits in the same home office, but I'm kind of used to the noise as I have a fileserver and an ESXI server and a large printer.

Anyway, we're going off topic. Happy to print an adaptor and can recommend the Ender 3 Pro (regardless of motherboard version).

Rob

DBT85

Established Member

See all of this faffing with boards or BL Touches would get right on my thrupennys. I'm only 35 but after years of being the go to IT guy for people I am now in a period of "Just work damnit". My time is limited enough without wanting to allocate more of it to fixing something that wasn't broken by adding a new bit that is supposed to be better! I'm lucky my experience was so good I think

rwillett

Established Member

I was the go to IT guy as well, I now tell people I'm an accountant and oddly enough, they never come back. I tried with my family but that failed miserably.

rwillett

Established Member

Some people have reported immediate success with BLtouch.

Mine was a real one, the version is somewhat vague which I suspect is the problem, I can level my bed just as fast as auto bed levelling so I don't care any more. The Bltouch is sitting the shelf.

Mine was a real one, the version is somewhat vague which I suspect is the problem, I can level my bed just as fast as auto bed levelling so I don't care any more. The Bltouch is sitting the shelf.

You probably know this, but BLTouch (with UBL) doesn't just level your bed corner to corner like you do manually, it also compensates for any undulations in your build plate which can make a huge difference to the adhesion of your 0.1mm layer if there's a 0.2mm dip somewhere on the plate.I can level my bed just as fast as auto bed levelling so I don't care any more.

rwillett

Established Member

@pcb1962

Yes I was aware it builds a mesh of points and their depths up and down relative to a plane. I realise it will compensate for undulations and not just for a simple dip or elevation in one place.

I spent a long time trying to debug the Marlin code to fix the issue with my Bltouch. I'd set it up for a 3x3 grid and it would do the first two rows correctly and then on the third row it looked as if the values for Z had been changed to positive (or negative) and would just launch itself upwards into the Z axis and never come down to the plate. It looked like some value got flipped, I suspect a memory leak or pointer going astray, but I couldn't find it so gave up. Other people had the same issue. It could also be a hardware incompatibility. Could be aliens as well

I'm pretty careful with manual bed levelling now and I don't use rafts at all. Just doing a six hour print job for a new frame for my dust shoe. The holes really take time to print as they need lots of work from the printer.

Rob

Yes I was aware it builds a mesh of points and their depths up and down relative to a plane. I realise it will compensate for undulations and not just for a simple dip or elevation in one place.

I spent a long time trying to debug the Marlin code to fix the issue with my Bltouch. I'd set it up for a 3x3 grid and it would do the first two rows correctly and then on the third row it looked as if the values for Z had been changed to positive (or negative) and would just launch itself upwards into the Z axis and never come down to the plate. It looked like some value got flipped, I suspect a memory leak or pointer going astray, but I couldn't find it so gave up. Other people had the same issue. It could also be a hardware incompatibility. Could be aliens as well

I'm pretty careful with manual bed levelling now and I don't use rafts at all. Just doing a six hour print job for a new frame for my dust shoe. The holes really take time to print as they need lots of work from the printer.

Rob

Ender 3 pro here. Printed lots of feather boards, clamps, etc, now experimenting with dogs. All adaptions from thingiverse

For bed levelling, buy a glass bed or mirror tile, much more level and consistent, then do the paper trick. Takes two minutes, once every few days. I’ve a bl touch, that I’ve not installed, probably won’t as the paper thing is so easy with the glass.

Replace stock springs under bed with ‘yellow’ firmer ones. Helps with keeping bed level once you’ve levelled it.

For curling part 1. I’ve put 5 70x70mm thermal pads between the heated bed and glass build plate. Placed in dice ‘5 dot‘ pattern. This gives an even distribution and helps prevent curling as well as sticking builds.

For curling part 2. Always clean the glass bed between builds with a mixture of 10% alcohol 90% water. Spray it on and wipe down with a lint free cloth. This is very important.

Releasing built parts from bed that may be stuck. Squirt your ‘cleaning’ solution onto the finished model after the temp has dropped a little. You’ll actually here the part ‘crack’ as it comes away from the glass bed.

Replace stock filament feeder with an aluminium one, more robust and as pointed out, the tension seems much better.

If noise is an issue and you don’t want to replace the board, place printer on a paving stone with some sort of damping material under it, some sliced foam packaging etc. Works wonders. Failing that, print off the damping feet on thingiverse.

I only use pla plus and have slightly raised my temps to 60 and 210, this works for me and stops stringing and bed adhesion fails.

All above are from other peoples tips that I’ve used, they work for me, may be worth a look.

I avoid CAD and try and stick with thingiverse only going bespoke if required. Not averse to CAD, I started in the 80’s with it and it’s likely paid off my mortgage one way or another, but it gets to be a pain.

For slicing, I’m on a Mac so use Cura with my adapted material profiles, pop it onto the octoprint server and off it goes. My only thing is I wish it was quicker.

Maybe if people are averse to CAD, those who are enjoying it could provide some sort of bureau service by emailing STL files of models they’ve created or hosting it somewhere. I’m sure between us all we could quickly build up a library. Anyone any thoughts on this? Maybe running off a load of parametric adapters and dropping them into a shared collection in thingiverse or drop box.

For bed levelling, buy a glass bed or mirror tile, much more level and consistent, then do the paper trick. Takes two minutes, once every few days. I’ve a bl touch, that I’ve not installed, probably won’t as the paper thing is so easy with the glass.

Replace stock springs under bed with ‘yellow’ firmer ones. Helps with keeping bed level once you’ve levelled it.

For curling part 1. I’ve put 5 70x70mm thermal pads between the heated bed and glass build plate. Placed in dice ‘5 dot‘ pattern. This gives an even distribution and helps prevent curling as well as sticking builds.

For curling part 2. Always clean the glass bed between builds with a mixture of 10% alcohol 90% water. Spray it on and wipe down with a lint free cloth. This is very important.

Releasing built parts from bed that may be stuck. Squirt your ‘cleaning’ solution onto the finished model after the temp has dropped a little. You’ll actually here the part ‘crack’ as it comes away from the glass bed.

Replace stock filament feeder with an aluminium one, more robust and as pointed out, the tension seems much better.

If noise is an issue and you don’t want to replace the board, place printer on a paving stone with some sort of damping material under it, some sliced foam packaging etc. Works wonders. Failing that, print off the damping feet on thingiverse.

I only use pla plus and have slightly raised my temps to 60 and 210, this works for me and stops stringing and bed adhesion fails.

All above are from other peoples tips that I’ve used, they work for me, may be worth a look.

I avoid CAD and try and stick with thingiverse only going bespoke if required. Not averse to CAD, I started in the 80’s with it and it’s likely paid off my mortgage one way or another, but it gets to be a pain.

For slicing, I’m on a Mac so use Cura with my adapted material profiles, pop it onto the octoprint server and off it goes. My only thing is I wish it was quicker.

Maybe if people are averse to CAD, those who are enjoying it could provide some sort of bureau service by emailing STL files of models they’ve created or hosting it somewhere. I’m sure between us all we could quickly build up a library. Anyone any thoughts on this? Maybe running off a load of parametric adapters and dropping them into a shared collection in thingiverse or drop box.

XH558

Established Member

Wow,

Is there any user here who would produce some adaptors with sensible pricing + p&p?

Would like a couple of adapters and a Y piece for my Router table?

Anyone consider it?

Is there any user here who would produce some adaptors with sensible pricing + p&p?

Would like a couple of adapters and a Y piece for my Router table?

Anyone consider it?

DBT85

Established Member

If you give some dimensions we can draw some up, unless you've done that bit already. Cost of the print itself isn't really much of a factor. Electricity and filament brings one adapter to probably 50p. Posting it will naturally cost more. The further issue is you tell me 58mm internal, I print 58mm internal and its actually meant to be 58.1mm internal. Having the printer on hand means you can check that stuff before doing a whole print.

Draw what you want and give dimensions and I'll draw it up and we can see what occurs. Need things like length, inner diameter, outer diameter (or just the important one and a thickness if you prefer).

Can't promise owt as I've not much filament and the only time I get spare to draw much is when I'm working

Draw what you want and give dimensions and I'll draw it up and we can see what occurs. Need things like length, inner diameter, outer diameter (or just the important one and a thickness if you prefer).

Can't promise owt as I've not much filament and the only time I get spare to draw much is when I'm working

pe2dave

Established Member

DBT85

Established Member

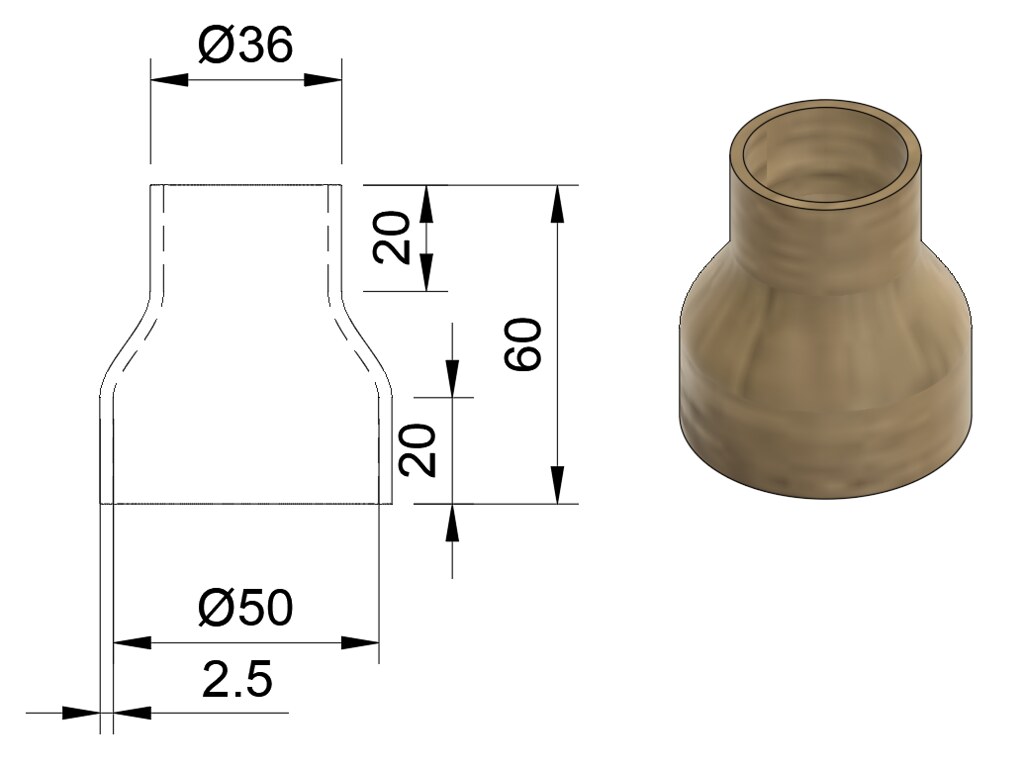

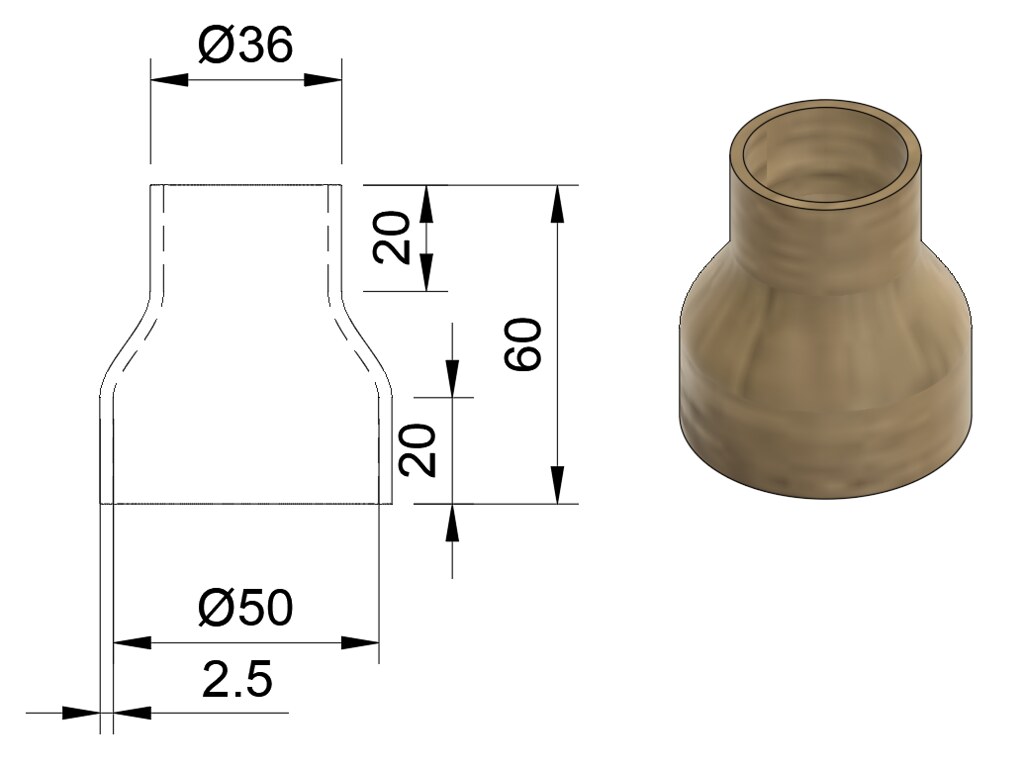

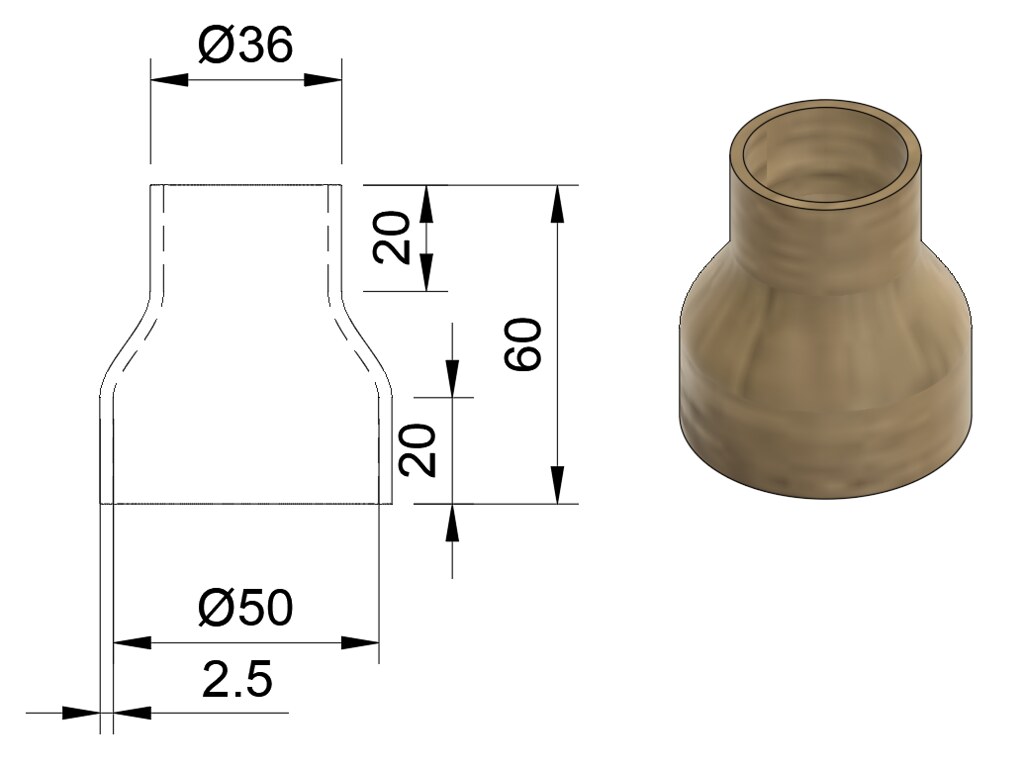

Dave, forgive me for maybe not seeing clearly but can you clear up the ambiguity in your dimensions.

"Cyclone output 50mm internal" Is the 50mm the internal diameter of the 3d printed coupler (to go outside the cyclone) or is 50mm the external diameter of the coupler (to go inside the cyclone)

Similarly, "Shopvac 36mm external". Is the 36mm the external diameter of the 3d printed coupler (to go inside the vac) or is 36mm the internal diameter of the coupler (to go outside the vac).

This is how I have it drawn at the moment. Please note the 36mm diameter is the OUTER and the 50mm diameter is the INNER.

"Cyclone output 50mm internal" Is the 50mm the internal diameter of the 3d printed coupler (to go outside the cyclone) or is 50mm the external diameter of the coupler (to go inside the cyclone)

Similarly, "Shopvac 36mm external". Is the 36mm the external diameter of the 3d printed coupler (to go inside the vac) or is 36mm the internal diameter of the coupler (to go outside the vac).

This is how I have it drawn at the moment. Please note the 36mm diameter is the OUTER and the 50mm diameter is the INNER.

Last edited:

pe2dave

Established Member

No problem - trying to buy hoses and couplers is quite .. annoying.Dave, forgive me for maybe not seeing clearly but can you clear up the ambiguity in your dimensions.

"Cyclone output 50mm internal" Is the 50mm the internal diameter of the 3d printed coupler (to go outside the cyclone) or is 50mm the external diameter of the coupler (to go inside the cyclone)

Similarly, "Shopvac 36mm external". Is the 36mm the external diameter of the 3d printed coupler (to go inside the vac) or is 36mm the internal diameter of the coupler (to go outside the vac).

This is how I have it drawn at the moment.

50mm is the internal diameter of the connection on the cyclone.

So the coupler would need to go inside this (ext dimension is 56 mm if you wanted to go over it).

The other end of the coupler (I think) should go over the vac input. That is 34.5mm

So (my view): Coupler narrow end, internal should be 34.5 (say 35, for vac to go inside)

Wide end, 56+ to go over the cyclone output.

<grin/> Tricky terminology !

Does that make sense?

Similar threads

- Replies

- 10

- Views

- 1K

- Replies

- 14

- Views

- 4K