As a newbie to the forum I hope I'm posting this in the correct place.

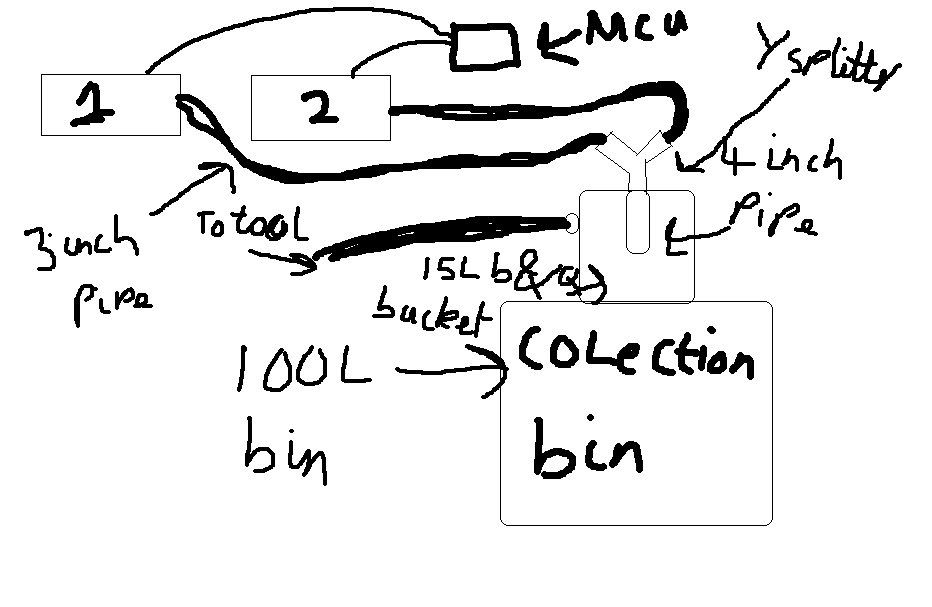

I'm looking for advice as to the most appropriate dust extractor to purchase. It will be used to extract from a startrite table saw & bandsaw along with a hp/t. Two particular models that I'm considering are the rojek R2002 and the MetaboClean20, does anybody have experience of either of these.

I would also appreciate advice on ducting. The above use either 150mm or 180mm ducting, I know the likes of Axminster can supply 100mm ducting, but are there many sources of the larger diameters available.

The extractor will be housed in garage which is seperated from the workshop by a stud partion wall and therefore fine extraction is not critical.

Hopefully I've not repeated two many previously answered questions.

Regards,

Geoff.

I'm looking for advice as to the most appropriate dust extractor to purchase. It will be used to extract from a startrite table saw & bandsaw along with a hp/t. Two particular models that I'm considering are the rojek R2002 and the MetaboClean20, does anybody have experience of either of these.

I would also appreciate advice on ducting. The above use either 150mm or 180mm ducting, I know the likes of Axminster can supply 100mm ducting, but are there many sources of the larger diameters available.

The extractor will be housed in garage which is seperated from the workshop by a stud partion wall and therefore fine extraction is not critical.

Hopefully I've not repeated two many previously answered questions.

Regards,

Geoff.