jimi43

Established Member

Hi All

On Sunday I picked up a few odds and ends at the bootfair but digging in boxes of rusty tools sometimes brings up some gems...

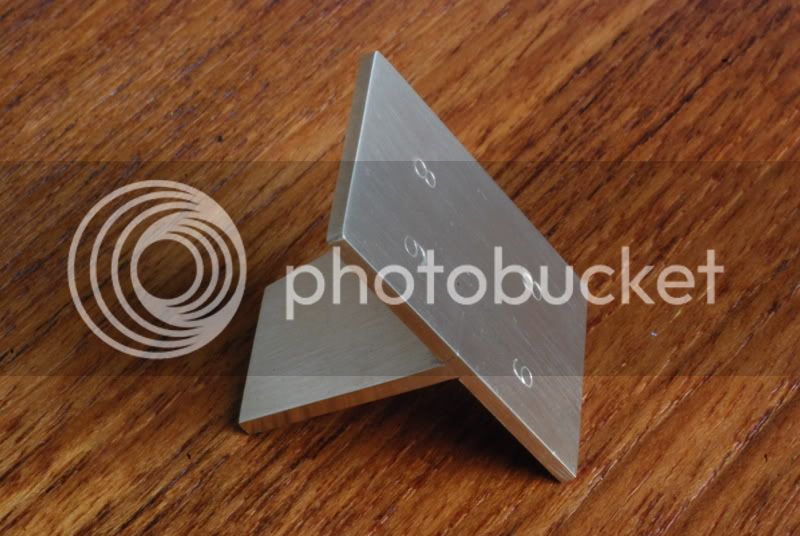

I have wanted a dovetail marker for sometime and so....finding this little baby in the bottom of a box of junk was a real find for me..

Someone has obviously made this in metal probably for metal dovetails but it worked fine on wood of course...but the interesting thing for me was the holes in the plate...these make excellent depth markers...clearly for standard tails....and for 50p a real bargain!

Just posted it up in case anyone was into making one...really simple bit of square stock...nicely finished with a piece of plate riveted to it.

Cheers

Jim

On Sunday I picked up a few odds and ends at the bootfair but digging in boxes of rusty tools sometimes brings up some gems...

I have wanted a dovetail marker for sometime and so....finding this little baby in the bottom of a box of junk was a real find for me..

Someone has obviously made this in metal probably for metal dovetails but it worked fine on wood of course...but the interesting thing for me was the holes in the plate...these make excellent depth markers...clearly for standard tails....and for 50p a real bargain!

Just posted it up in case anyone was into making one...really simple bit of square stock...nicely finished with a piece of plate riveted to it.

Cheers

Jim