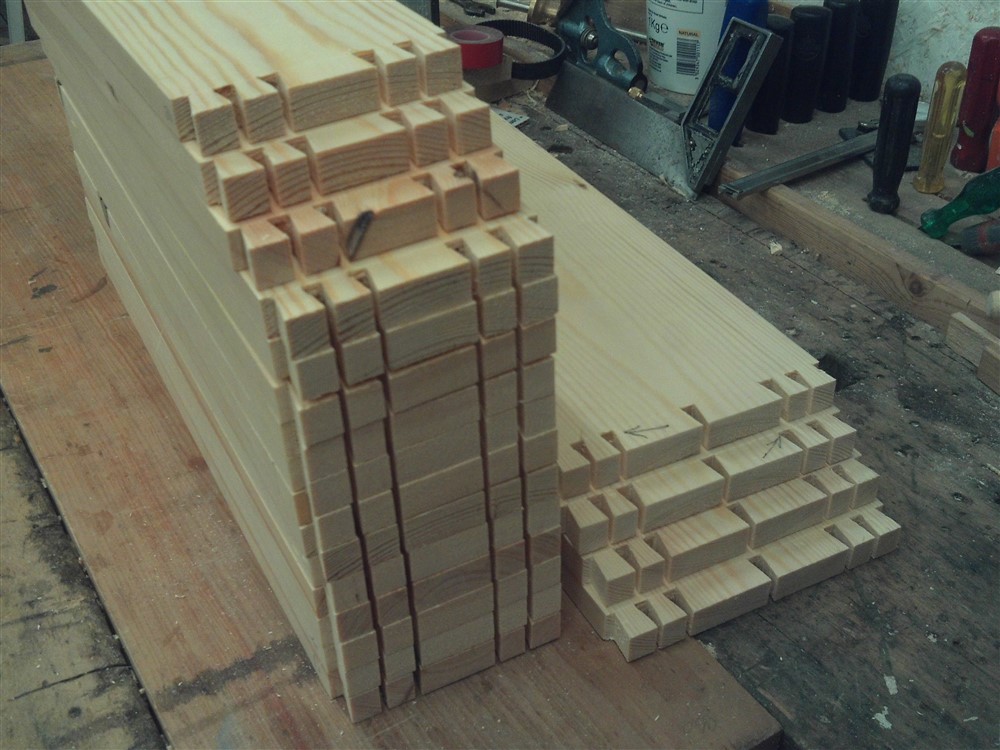

I have just made my first attempt at dovetail joints on some drawer boxes for my workshop.

I had some low grade pine that I wanted to use up so I milled it down to size and started with the tails. When cutting out the waste I found that the wood was too soft for my sharp chisel to cut across the grain. The wood just crushed even with a gentle bump using my hand. The solution I used was to bandsaw the waste out and smooth to the lines with a file.

Is the reason for this down to the poor quality pine?

I had some low grade pine that I wanted to use up so I milled it down to size and started with the tails. When cutting out the waste I found that the wood was too soft for my sharp chisel to cut across the grain. The wood just crushed even with a gentle bump using my hand. The solution I used was to bandsaw the waste out and smooth to the lines with a file.

Is the reason for this down to the poor quality pine?