jimi43

Established Member

Some time back my dear friend RichardT bought an EXTRA EXTRA COARSE DMT diamond stone because Richard was into all things large and metallic so this was the sort of thing I should have expected Richard would buy.

The purpose was to move metal and move metal quickly...on plane irons mostly..creating a flat and a bevel of note by hand.

So..I was thinking about creating a face on my next project iron and remembered his favourable comments so..if it was good enough for Richard to rave about then it's good enough for me so I bought one...

Actually...it would be better to say I "invested" in one...rather as one does a house...or gold shares...or a villa in Spain....

At almost £110 (don't show Anne!!!)....this is quite an expensive bit of kit...and substantially more than the simple "EXTRA"...you pay about half as much again for the other "EXTRA"....

So it was going to be interesting to see if this crazy purchase was in fact...worth it....

Well...all I can say is YES...YES and YES it is worth it....without doubt.

This stone rips hardened steel apart like it was butter! Well not quite...but it's blinking good!

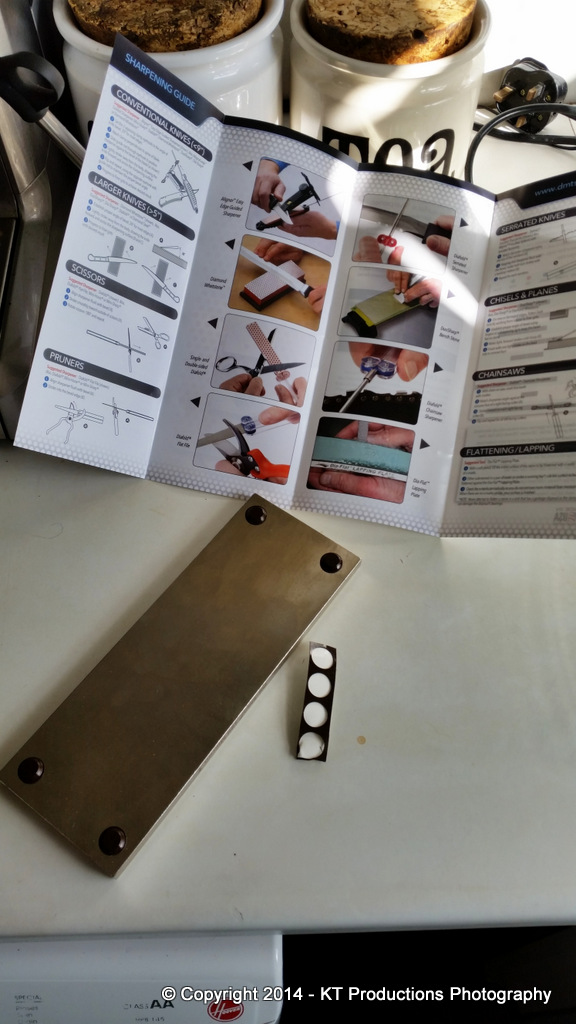

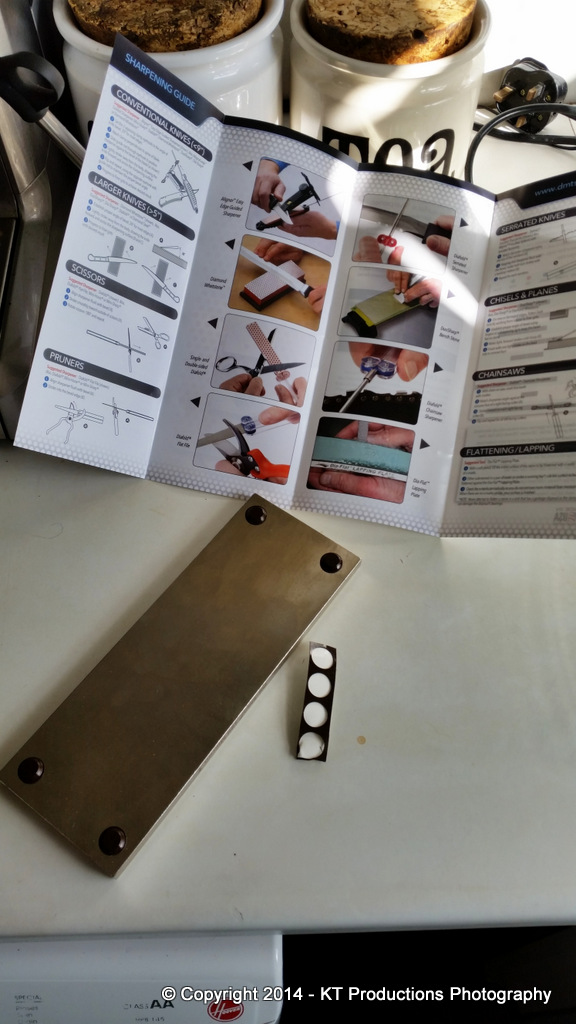

First of all may I say the simplest things are the best and this "stone" comes with just that...

Stick on feet! No more sliding or sticking pins in your fingers instead of the bench...no more stupid boxes made of walnut whip...or dreadful plastic...just four sticky brown plastic feet! Refreshing and totally effective...didn't budge an inch!

I wanted also to test how clean this method was...so I did it on the kitchen work surface whilst Annie was out at work...he he! :mrgreen:

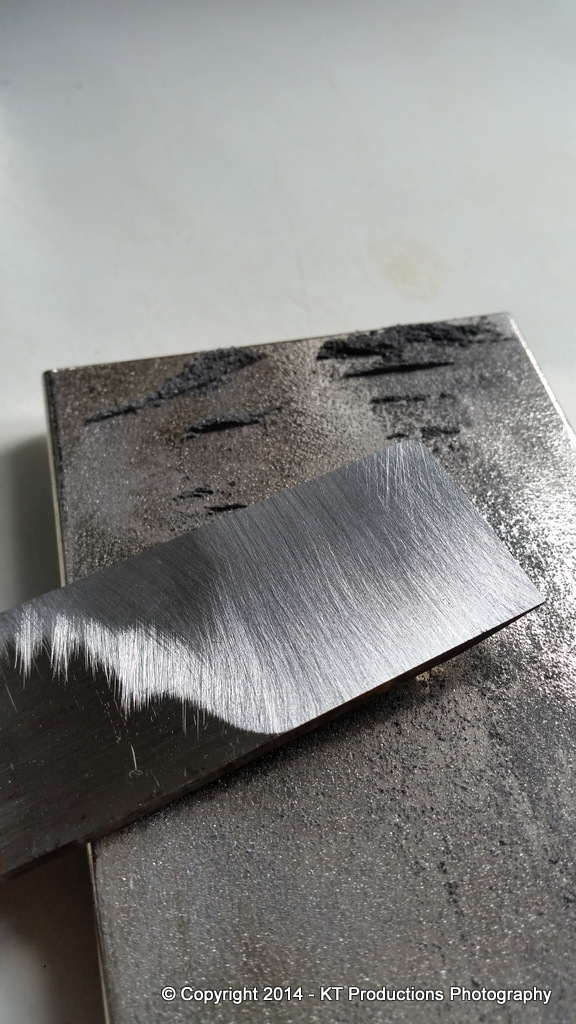

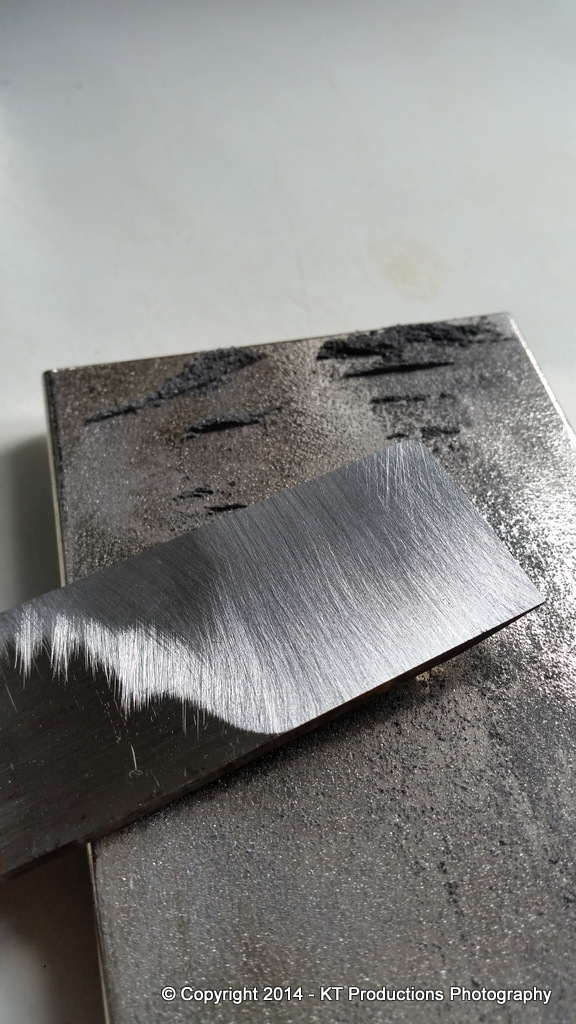

This was the test iron...because I didn't want to be there all day and this little Isaac Greaves may well form the ammunition part of my next plane...so off we go...

...so as we can see...not very flat at all.

Ideal!

And one of the worst "not flat" scenarios...fat in the middle and thin at the edges with extra thin bits to the edge area...perfect!

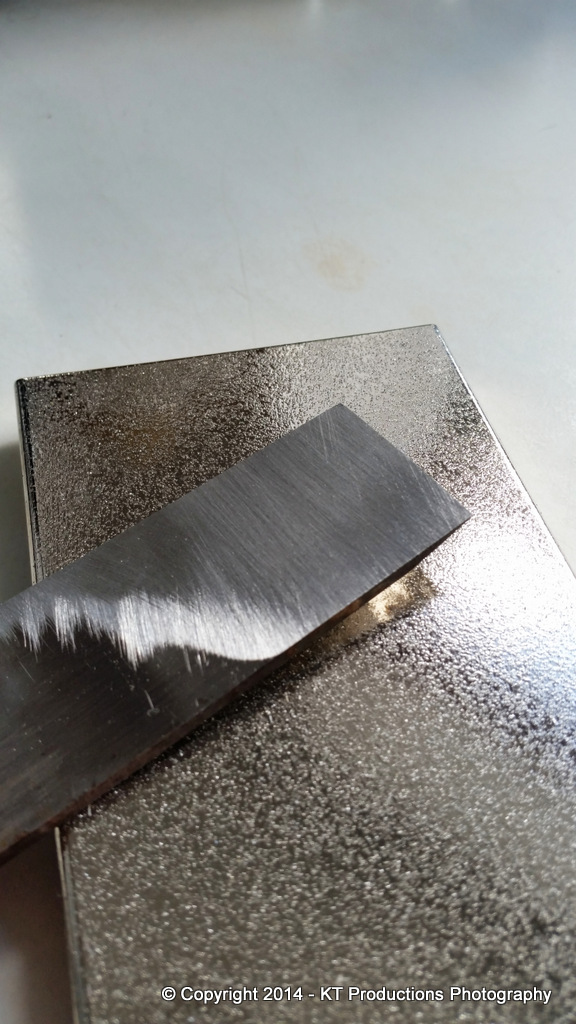

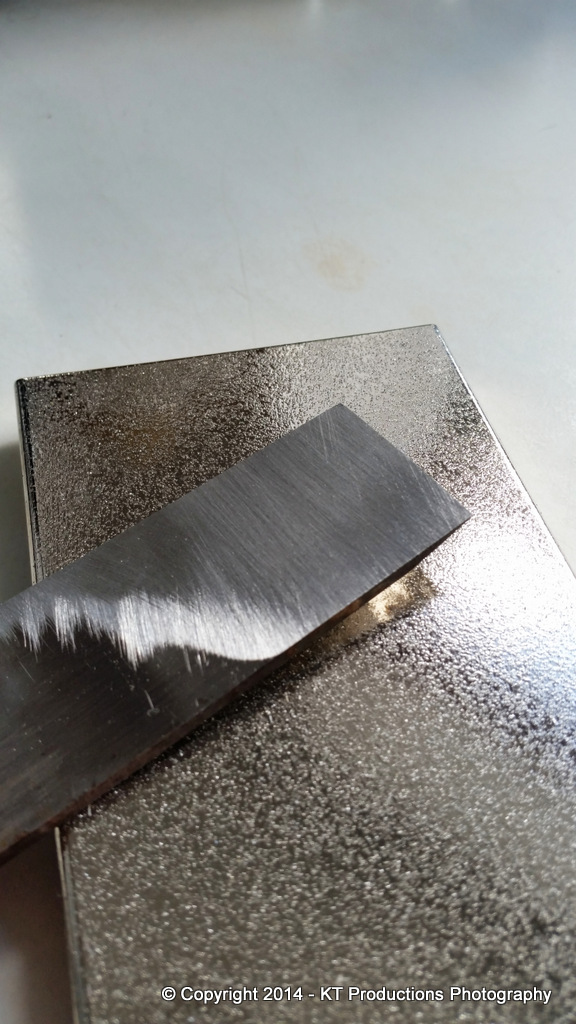

About half an hour later....and with lunch in between...oh and the postman coming with my new tap and die...

...and what's more...not ONE speck of dust on the worktop...

....it all stayed on the steel plate! Now that's impressive...and you can just see how much steel it removed!

Clean up...carefully take into the garden and blow! That was it!

All the dust just blew away!

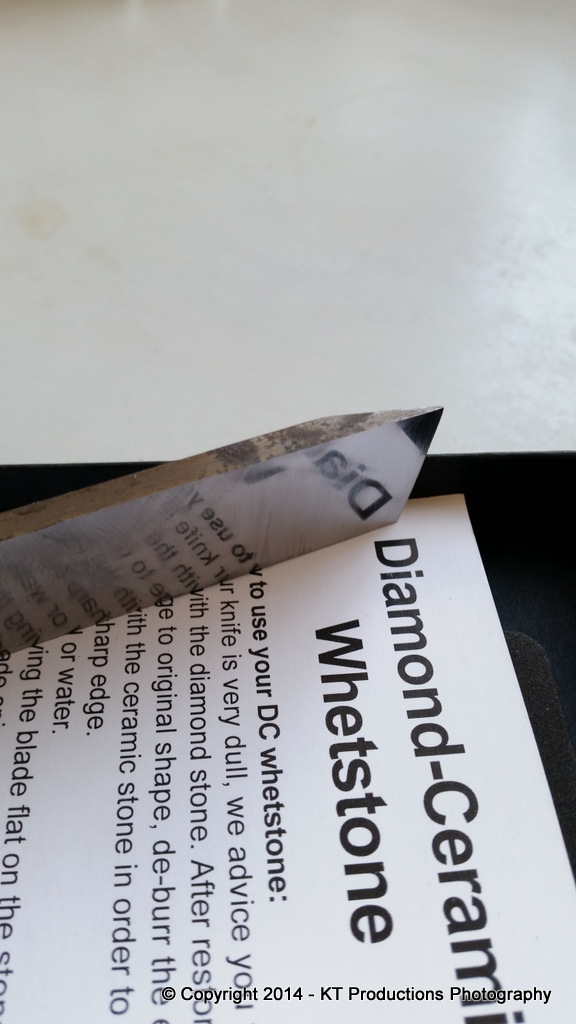

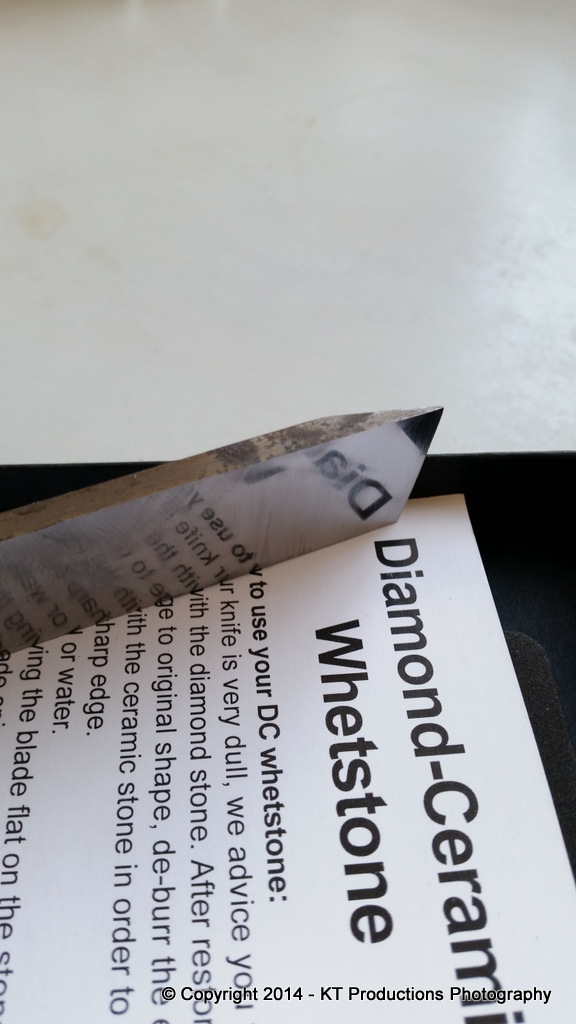

So was it flat...well...I took it to the Fallkniven stone...coarse (no extras here!)..then medium and then a fine ceramic...

....yeh...I'd say that was flat!

So...in summary...

Cons: HUGELY expensive...Liz Taylor expensive

Pros: Super fast cutting, nicely flat finish, very clean use and clean up and finally...those dinky feet...perfect!

Would I buy one? Hell no...this one's for a bloke down the pub who keeps ferrets...nothing to do with me..he's paying me back tonight love...honest! :mrgreen:

Cheers

Jimi

The purpose was to move metal and move metal quickly...on plane irons mostly..creating a flat and a bevel of note by hand.

So..I was thinking about creating a face on my next project iron and remembered his favourable comments so..if it was good enough for Richard to rave about then it's good enough for me so I bought one...

Actually...it would be better to say I "invested" in one...rather as one does a house...or gold shares...or a villa in Spain....

At almost £110 (don't show Anne!!!)....this is quite an expensive bit of kit...and substantially more than the simple "EXTRA"...you pay about half as much again for the other "EXTRA"....

So it was going to be interesting to see if this crazy purchase was in fact...worth it....

Well...all I can say is YES...YES and YES it is worth it....without doubt.

This stone rips hardened steel apart like it was butter! Well not quite...but it's blinking good!

First of all may I say the simplest things are the best and this "stone" comes with just that...

Stick on feet! No more sliding or sticking pins in your fingers instead of the bench...no more stupid boxes made of walnut whip...or dreadful plastic...just four sticky brown plastic feet! Refreshing and totally effective...didn't budge an inch!

I wanted also to test how clean this method was...so I did it on the kitchen work surface whilst Annie was out at work...he he! :mrgreen:

This was the test iron...because I didn't want to be there all day and this little Isaac Greaves may well form the ammunition part of my next plane...so off we go...

...so as we can see...not very flat at all.

Ideal!

And one of the worst "not flat" scenarios...fat in the middle and thin at the edges with extra thin bits to the edge area...perfect!

About half an hour later....and with lunch in between...oh and the postman coming with my new tap and die...

...and what's more...not ONE speck of dust on the worktop...

....it all stayed on the steel plate! Now that's impressive...and you can just see how much steel it removed!

Clean up...carefully take into the garden and blow! That was it!

All the dust just blew away!

So was it flat...well...I took it to the Fallkniven stone...coarse (no extras here!)..then medium and then a fine ceramic...

....yeh...I'd say that was flat!

So...in summary...

Cons: HUGELY expensive...Liz Taylor expensive

Pros: Super fast cutting, nicely flat finish, very clean use and clean up and finally...those dinky feet...perfect!

Would I buy one? Hell no...this one's for a bloke down the pub who keeps ferrets...nothing to do with me..he's paying me back tonight love...honest! :mrgreen:

Cheers

Jimi