johnelliott":3202eoj0 said:

Presumably when these programmes are made, the time taken to change the blade over is edited out

I'll bet it is. You can spend ages faffing around with shims and still be a cats whisker out. The best solution I've seen to this is the Dial-a-Width type approach taken by Freud with their

SD600 series dado heads

cutting42":3202eoj0 said:

It is clear that the standard riving knife and guard assembly cannot be used when cutting a dado but can other guards be used. I assume the other area of risk is the fact that there are more saw blades in contact with the wood thereby increasing the risk of kickback.

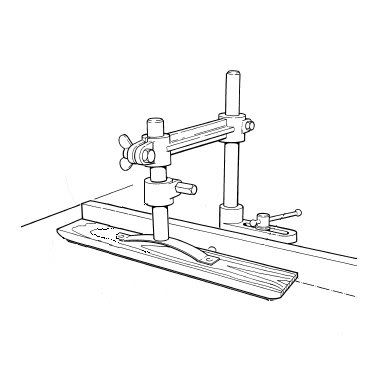

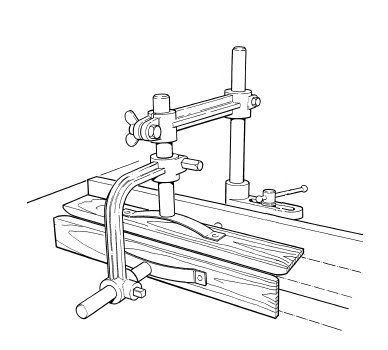

Got it in one! Guarding is probably the biggest single problem. If you are using the dado head to produce a rebate at the edge of a work piece it should be relatively straightforward to add a top Shaw guard mechanism like this:

to the machine in order to apply downwards pressure AND act as a safety guard. A commercial overhead guard, such as the American Brett guard

provides adequate overhead guarding if properly adjusted, but

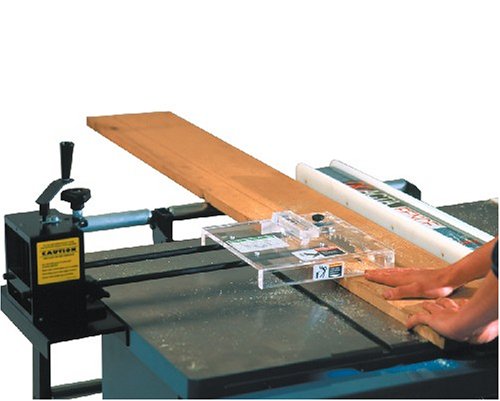

fails singularly to address the need for downwards pressure. A Shaw guard on the other hand will overcome any tendency for the piece to tip or be accidentally lifted from the rear by the saw operator and be caught on the rising teeth (which is one thing that causes a kickback). A power feeder would achieve pretty much the same result. For narrower pieces where there may be difficulty in holding the work in against the fence a Shaw guard with a side pressure plate should be used:

or alternatively feather boards added for side pressure.

Note that to install the Shaw guard properly it should either be bolted to the top of the saw bench, or if mounted on the rip fence then the rip fence will need to be of a design, such as the fore and aft locking style used on older Wadkins and Startrites, that it cannot be lifted in the event of a kickback. Trade rated saws which were designed to be used with dado heads, such as the Wadkin PP and PK, tend to have heavy cast iron rip fence frames which are securely locked onto a 40 or 50mm diameter solid steel bar. Another thing you need to do is select timbers with no major knots and make sure thare are no cracks or voids (reasons two and three for kickback with a stacked dado head). But the fact that a stacked dado saw head is not an anti-kickback design means that there will always be some inherent risk of kickback (and is the thing which effectively outlaws them in trade shops as a general-use tool - they simply don't meet current tooling/guarding regs). Scheppach/Kity actually have a head for their machines which is rather like a spindle moulder cutter block and is inherrently less likely to kickback, even without a Shaw guard in place

Above: The Scheppach 7986 2000 Adjustable groove cutter for use on Schepach TS series saws. Allows 5 to 9.8mm wide grooves to be cut, the larger 6320 8100 cutter allows 8 to 15mm wide grooves to be cut

and they recommend using a crown guard on a boom arm (the so-called SUVA guard after the Swiss insurance safety test laboratory which specified it) when using these cutters.

Below: Scheppach 5460 1100 SUVA Guard

Scheppach aren't the only people with this type of approach, Felder/Hammer offer a couple of anti-kickback spindle-moulder type groove cutters available for use on their saws, designed for use with an overhead (SUVA-type) guard, however they are fixed groove width design.

The biggest problem, however, comes when you want to use a stacked dado head the produce a through housing in the middle of a piece, such as you would require for a bookcase. Here it becomes almost impossible to guard adequately so that the top of the blade is covered AND provide downwards pressure. It would require some form of boom mechanism with a wide Shaw guard mounted on it and I can see problems in building that - getting enough clearance and sufficient rigidity into the structure to resist a kickback would probably require it to be ceiling mounted. Perhaps someone can come up with an alternative design such as a crosscut carraige with clamping and top guards where the travel can be limited?

It is for this reason that I and others regard a radial arm saw and a dado head as a safer option for cutting through housings or trenching.

As yet I haven't mentioned the other problem with dado heads - braking. All modern table saws are designed with a motor brake, generally either mechanical or electronic (DC injection) which stops the blade rotation in under 10 seconds. With a stacked dado set there is a question about how you are going to lock that cutter set onto the arbor so that it won't move (nut unscrewing) under braking and in doing so inadvertently turn the chippers into the woodworking equivalent of Bruce Lee's ninja stars! At the very least a second nut, or lock nut, needs to be added to the arbor to reduce the risk of the one nut unscrewing itself under braking. It may also be found that the brake is totally ineffective when trying to brake the greater weight if the dado set. Take the brake off or disable it and (at least in a commercial shop) you again have an illegal saw.

I would also appreciate any advice on this as like bramers and others here I am sure have not been around woodworking long enough to hear the historical reasons why dados have such a bad press. I have done a bit of a search and seen lots of opinions for and against but not why?

Well that's about as positive as I can be, I'm afraid. I try to have respect for the machinery I use and my comments about limiter tooling are based very much on the experience I had of sticking a thumb into a large diameter cutter on a pin router - being a limiter cutter my thumb was thrown out (not before getting 20+ lacerations), non-limiter tooling such as the dado head will tend to draw fingers, etc in and generate hamburger - the sort of stuff that can't be sewn back on or stitched up, like a circular saw blade only worse. Remember that before using one.

Apologies to those who's derriers are now bored off by the whole subject

.....

Scrit

:?

:?

OR

OR  :?:

:?: