Here's a problem that may require thinking caps to be put on (or maybe not for the experts amongst us).

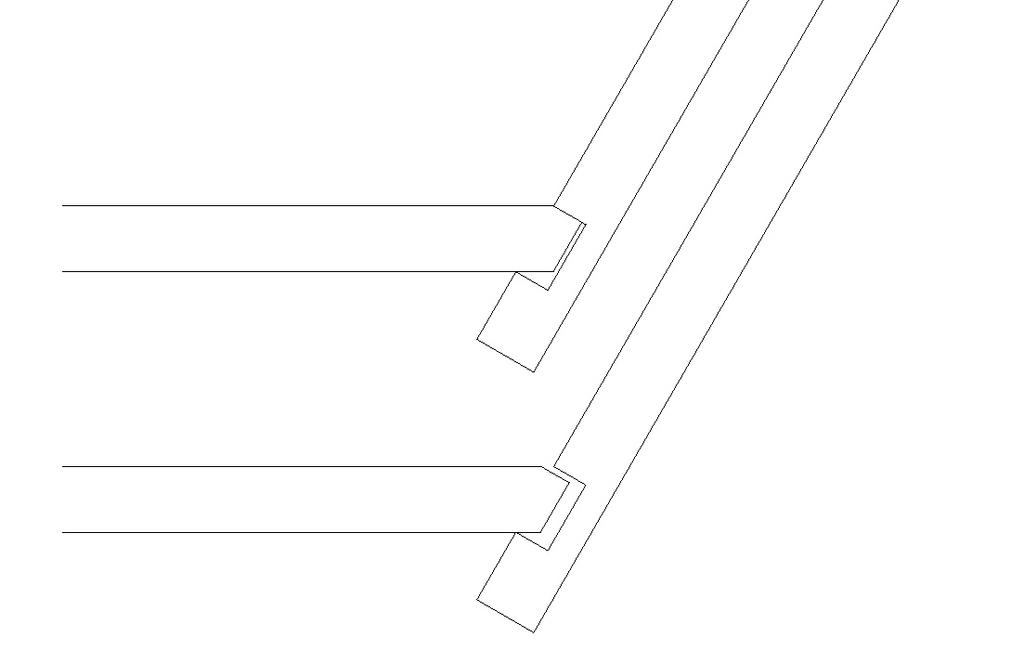

I'm working on a tea tray at the moment and thought it would look nice if the two end "walls" (for want of a better word) were angled to lean outwards. Given that I want the bottom to sit loose in a groove in all the sides/walls, this would necessitate the groove in the ends to be cut not perpendicular to the surfaces of the end walls.

I did a bit of experimenting yesterday: held a piece of wood at what looked like a pleasing angle, marked horizontal near the base and pared away to the required angle. That was quite simple to do and I had a nice leaning bit of wood (I wonder if this is how they made the initial model of the Leaning Tower of Pisa :mrgreen: ). Then I cut a roughly (it was only a feasibility experiment with pieces of scrap) angled fence for the plough plane and hat a go at the groove on a normal, square piece of wood. This was impractical cum disastrous because with such an arrangement one corner of the plough blade inevitably digs in first and I found it difficult to control. Maybe it would work by going slowly at it but would one get consistent results?

I came to the conclusion that the only way to do this would be to cut a batten with an angled side, clamp that across the piece of wood and saw the groove in. That way consistent angles at both ends would be achieved. Then it should be just a matter of showing the ends to the unangled, long side walls and cutting grooves in conventionally on them. At this point I got brain ache because I couldn't work out the angle for the batten and decided to sleep on it. (In fact it is a hell of a job calculating the angles. I measured my pared piece as leaning at an angle of 32°.)

I should imagine that the experienced pro would:

a. Already know what all the angles should be.

b. Just cut the angled groove with a tilted table saw blade.

But what is the best method for doing this by hand?

Meanwhile, because I want to get this tray done fairly soon, this one is going to have simple vertical walls but I think I'd like to be able to have tilted end walls on a future one.

Thoughts?

I'm working on a tea tray at the moment and thought it would look nice if the two end "walls" (for want of a better word) were angled to lean outwards. Given that I want the bottom to sit loose in a groove in all the sides/walls, this would necessitate the groove in the ends to be cut not perpendicular to the surfaces of the end walls.

I did a bit of experimenting yesterday: held a piece of wood at what looked like a pleasing angle, marked horizontal near the base and pared away to the required angle. That was quite simple to do and I had a nice leaning bit of wood (I wonder if this is how they made the initial model of the Leaning Tower of Pisa :mrgreen: ). Then I cut a roughly (it was only a feasibility experiment with pieces of scrap) angled fence for the plough plane and hat a go at the groove on a normal, square piece of wood. This was impractical cum disastrous because with such an arrangement one corner of the plough blade inevitably digs in first and I found it difficult to control. Maybe it would work by going slowly at it but would one get consistent results?

I came to the conclusion that the only way to do this would be to cut a batten with an angled side, clamp that across the piece of wood and saw the groove in. That way consistent angles at both ends would be achieved. Then it should be just a matter of showing the ends to the unangled, long side walls and cutting grooves in conventionally on them. At this point I got brain ache because I couldn't work out the angle for the batten and decided to sleep on it. (In fact it is a hell of a job calculating the angles. I measured my pared piece as leaning at an angle of 32°.)

I should imagine that the experienced pro would:

a. Already know what all the angles should be.

b. Just cut the angled groove with a tilted table saw blade.

But what is the best method for doing this by hand?

Meanwhile, because I want to get this tray done fairly soon, this one is going to have simple vertical walls but I think I'd like to be able to have tilted end walls on a future one.

Thoughts?