dicktimber

Established Member

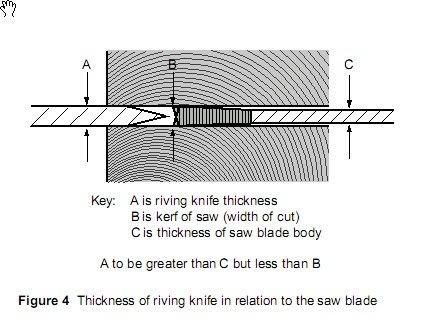

What thickness should the riving knife be?

Should it be thicker than the table saw blade thickness, or the same thickness?

I realise that the riving knife helps to stop binding and kickback while ripping timber due to releasing inbuilt stresses in the wood, but what happens when cutting ply sheet, and the sheet won't spread over the riving knife?

I was taught that on no account should the crown guard be removed, and have always used alternative methods to cut timber when, Norm works exclusively WITHOUT the crown guard in place. For example, tenon shoulders etc

It would be nice to know what approach other members use when difficulties arise with the crown guard in place?

Mike

Should it be thicker than the table saw blade thickness, or the same thickness?

I realise that the riving knife helps to stop binding and kickback while ripping timber due to releasing inbuilt stresses in the wood, but what happens when cutting ply sheet, and the sheet won't spread over the riving knife?

I was taught that on no account should the crown guard be removed, and have always used alternative methods to cut timber when, Norm works exclusively WITHOUT the crown guard in place. For example, tenon shoulders etc

It would be nice to know what approach other members use when difficulties arise with the crown guard in place?

Mike