I got a useful looking bit of metal at a car boot in France, which I assume was part of a vice or maybe press. I was wondering if anyone immediately sees a clever way to engineer it into a sort of tail vice for the workbench I’m building... it’s just the threaded part with the handle, a solid 100x100ish plate with threaded hole and a couple washers at the moment, and I feel like somethings missing... I’ve had a few ideas but nothing quite elegant enough to warrant enacting

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Could this be a vice...?

- Thread starter Dokkodo

- Start date

Help Support UKworkshop.co.uk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Lots of views but no replies yet, not sure why. I don't see any reason that couldn't be turned into an end vice, depending on the style you're thinking of you either fix the handle end or the threaded plate and let the other end move in and out.

Only possible niggle I can forsee is that the tommy bar is very long, which because this isn't a QR mechanism means it could get in the way sometimes. Not an absolute dealbreaker but something to think about depending on where that end of the bench will be positioned relative to other things, i.e. near a wall or a static power tool. Edit: and if your benchtop is low enough it just occurred to me that it might pose a risk to a nearby kneecap!

Only possible niggle I can forsee is that the tommy bar is very long, which because this isn't a QR mechanism means it could get in the way sometimes. Not an absolute dealbreaker but something to think about depending on where that end of the bench will be positioned relative to other things, i.e. near a wall or a static power tool. Edit: and if your benchtop is low enough it just occurred to me that it might pose a risk to a nearby kneecap!

Cheers!

I think simplest would be to fix the threaded plate and have the end push something that grabs.

Other downside is that the thread stops half way along the bar so the handle will always be sitting miles off the bench, unless I fit the threaded plate far into the bench but that also doesnt seem right.

Anyway thanks for the reply

I think simplest would be to fix the threaded plate and have the end push something that grabs.

Other downside is that the thread stops half way along the bar so the handle will always be sitting miles off the bench, unless I fit the threaded plate far into the bench but that also doesnt seem right.

Anyway thanks for the reply

worn thumbs

Established Member

It could be incorporated into a vice.It may have been part of a press in a former life.Is it less work to turn it into a vice or to sell it and look for a Record 52 1/2 on ebay?

novocaine

Established Member

it is a vice, just not in the way you think it is.

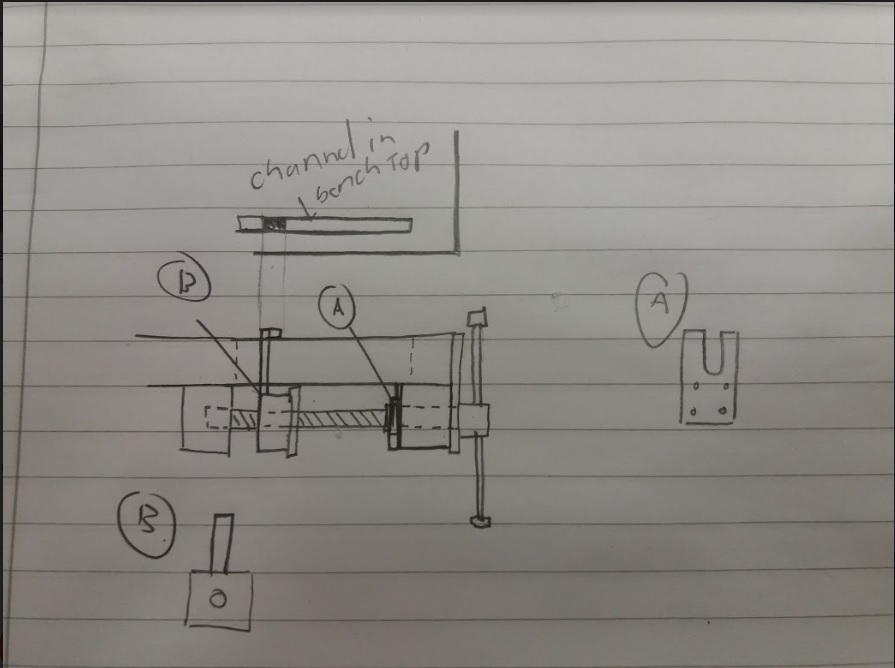

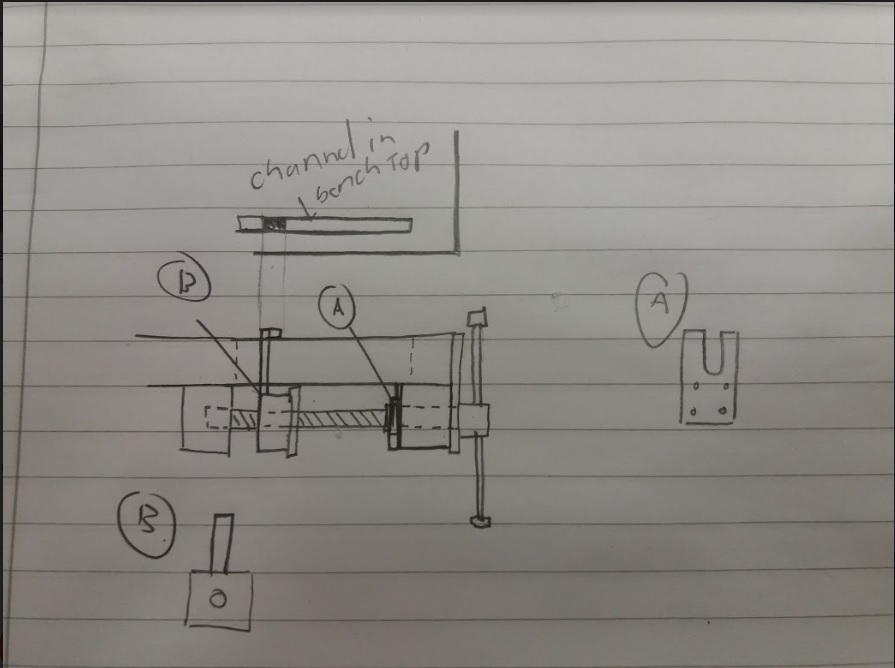

it's more suited to a sliding dog vise, so a channel in the bench that goes right through then a pin that extends above the top of the bench.

something like this.

not a whole lot of work to do and it's practicality is up to those who use this sort of thing to decide.

edit to add, it's called a Wagon Vise.

it's more suited to a sliding dog vise, so a channel in the bench that goes right through then a pin that extends above the top of the bench.

something like this.

not a whole lot of work to do and it's practicality is up to those who use this sort of thing to decide.

edit to add, it's called a Wagon Vise.

Attachments

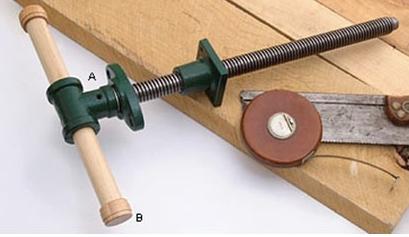

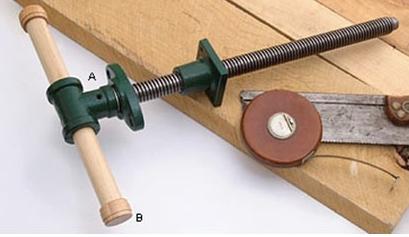

Looks like the tail vice screw I'm using to fit a leg vice. Not saying it is (I don't know anything) but it seems a similar set up at least. Wonder if that blank part of thread went through a big fat leg on an old French bench?

https://www.axminster.co.uk/veritas-tai ... rew-475227

I've turned the end screw on mine so the cone faces to the rear just because it seems to make more sense (and easier to fit. :-" )

Routed the housing before drilling the hole so I didn't lose my centre marks in case you're thinking 'What on Earth is he doing there...? '

Just wondering, not pretending to know.

Cheers,

Chris

https://www.axminster.co.uk/veritas-tai ... rew-475227

I've turned the end screw on mine so the cone faces to the rear just because it seems to make more sense (and easier to fit. :-" )

Routed the housing before drilling the hole so I didn't lose my centre marks in case you're thinking 'What on Earth is he doing there...? '

Just wondering, not pretending to know.

Cheers,

Chris

£9.99 (£1.00 / count)

£14.45 (£1.44 / count)

JSP M632 FFP3moulded Disposable Dustmask (Box of 10) One Size suitable for Construction, DIY, Industrial, Sanding, dust protection 99 Percent particle filtration Conforms and Complies to EN 149

Amazon.co.uk

£16.99

£19.99

Respirator Mask,Safety Dust Face Cover,Dust Face Cover Paint Face Cover,Gas Mask With Filter,For Paint,Dust And Formaldehyde,Sanding,Polishing,Spraying And Other Work

ShenZHEN CIRY MINGYANG LITIAN ELECTRONIC ECOMMERCE

£34.99 (£3.50 / count)

£39.99 (£4.00 / count)

VonHaus Chisel Set - 10pcs Woodworking Tools Set - Wood Carving Tools, Wood Chisel Sets with Sharpening Stone, Honing Guide and Storage Case

VonHaus UK

£10.19 (£0.39 / count)

£11.99 (£0.46 / count)

Nicpro Carpenter Pencil with Sharpener, Mechanical Carpenter Pencils Set with 26 Refills, Case, Deep Hole Marker Construction Pencils Heavy Duty Woodworking Pencils for Architect (Black, Red)

NicproShop EU

£15.99 (£1.60 / count)

£27.44 (£2.74 / count)

3M 8822 Disposable-fine dust mask FFP2 (10-pack)

Amazon.co.uk

£49.91

£58.33

Mefape Mortise and Tenon Jig Tools for Woodworking Routers, Tenon Cutter, Manual Mortising Machine, Invisible Slotting Machine Jig Stand, 3-Axis Guide Rail for Adjust Trimming Length and Width

wangshijuntianjinhongyuegongyipin

£10.10

£15.48

Portwest Browguard with Clear Visor, Size: One Size, Colour: Clear, PW91CLR

Amazon.co.uk

£199.00

£360.17

Trend Portable Benchtop Router Table with Robust Construction for Workshop & Site Use, 240V, CRT/MK3

Amazon.co.uk

£24.99

Facemoon Reusable Masks,Safety Masks,Dual Filter Masks, Paint, Dust, Epoxy Resin, Construction, Welding, Sanding, Woodworking, Chemical Reusable Gas Masks

ShenZHEN CIRY MINGYANG LITIAN ELECTRONIC ECOMMERCE

Already got a good side vice, i was thinking more along tail vice lines sorry I should have said. But its definitely most of the way there, whichever type of squasher it used to be! Compared to your photos chris, all thats missing is the second bracket.

Cheers novocaine, Ill research some wagon vice designs, seen a the HNT Gordon tail vices around on the web (this sorta thing) and although ive done without anything like that so far, looks like it could be for holding big flat things. This has removed my doubts enough to have a go!

Cheers novocaine, Ill research some wagon vice designs, seen a the HNT Gordon tail vices around on the web (this sorta thing) and although ive done without anything like that so far, looks like it could be for holding big flat things. This has removed my doubts enough to have a go!

novocaine

Established Member

refer to part A.  it's a U shaped metal tongue that sits behind the flange on the end of the shank (just at the end of the thread in your picture) with just a bit of free play fore/aft (about 2mm with an acme thread). because you've trapped the shank between the handle head and the flange the block will be the only thing that can move (in the Z axis), the threaded section will remain still so it can't fall out the block at the other end.

it's a U shaped metal tongue that sits behind the flange on the end of the shank (just at the end of the thread in your picture) with just a bit of free play fore/aft (about 2mm with an acme thread). because you've trapped the shank between the handle head and the flange the block will be the only thing that can move (in the Z axis), the threaded section will remain still so it can't fall out the block at the other end.

the block at the other end is just for support, normally you'd want to put a bearing surface in there but it isn't completely needed.

the block at the other end is just for support, normally you'd want to put a bearing surface in there but it isn't completely needed.

Don't apologise! I had no doubt Novocaine was right. He has form.Dokkodo":29rpinvd said:Already got a good side vice, i was thinking more along tail vice lines sorry I should have said. But its definitely most of the way there, whichever type of squasher it used to be! Compared to your photos chris, all thats missing is the second bracket.

Just thinking aloud. :wink:

novocaine

Established Member

ahhhhh, then yes you are missing a piece.  a gert big pair of nuts :shock: . you aren't likely to find them as it looks like a very old square thread form. so you have a couple of choices. 1 is a roll pin through the shaft, it will work but if you use it with dogs across the bench it may not stand up to the pressure (or it might to be honest, not that much force to hold wood still for planing) or a ring with a pair of grub screws and a small dimple or flat put in the shaft. both are easy enough to do.

a gert big pair of nuts :shock: . you aren't likely to find them as it looks like a very old square thread form. so you have a couple of choices. 1 is a roll pin through the shaft, it will work but if you use it with dogs across the bench it may not stand up to the pressure (or it might to be honest, not that much force to hold wood still for planing) or a ring with a pair of grub screws and a small dimple or flat put in the shaft. both are easy enough to do.

memzey

Established Member

Doesn’t the threaded screw part block the bottom of the moving block, making it difficult to raise and lower the dog?

Similar threads

- Replies

- 39

- Views

- 1K

- Replies

- 15

- Views

- 2K