Night Train

Established Member

That's fair enough, no point plaining waste.

Plan ahead though to make sure that you are able to hold and support the work to allow for planing, shaping and cramping later on.

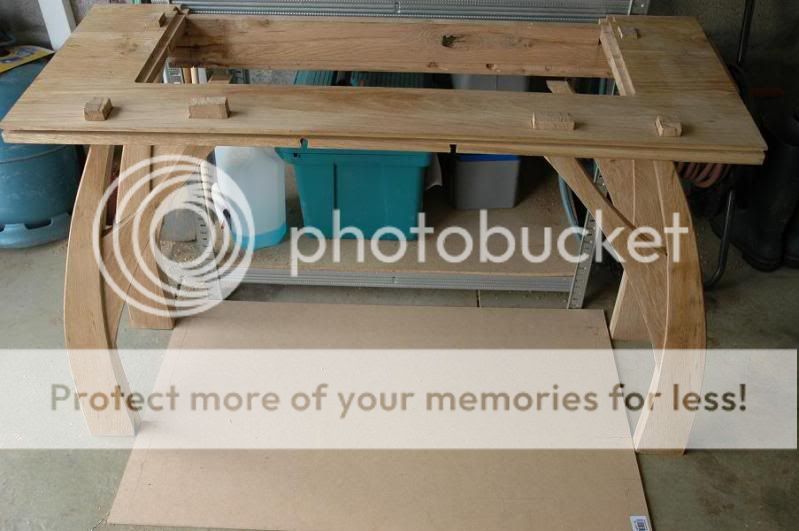

You can saw out the brace with a built in cramping block parallel to the back of the leg. The block can be sawn off later when it is assembled.

Plan ahead though to make sure that you are able to hold and support the work to allow for planing, shaping and cramping later on.

You can saw out the brace with a built in cramping block parallel to the back of the leg. The block can be sawn off later when it is assembled.