Well it is finally finished

Few more pictures from along the way first

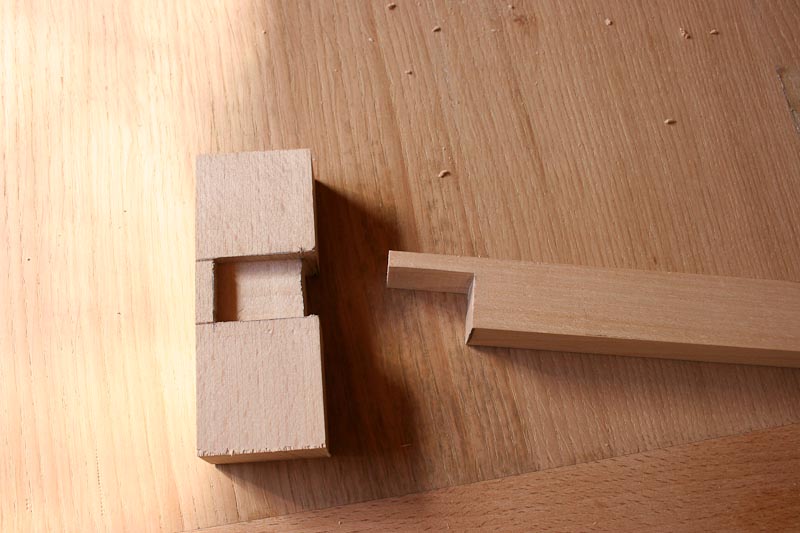

Wanted a strong joint to the handle so did this and glued it up before making the hand hole on the router table

So that the table panels were not wood on wood I drilled some 30mm holes and made some 'rubber' buttons from some semi hard foam with a fabric top surface that I had. You can also see a tapered hole that I added to locate the wings when extended.

This is the ground head of a stainless steel cap screw that is the alignment pin. It is set in the rail that has the wing fixed to it. This was taken with the table assembled so you can see that tapered hole above it.

I took advice at the Cressing Temple show and bought some finishing oil. Having tried it out on the leg frame and a test piece for the tops I have to say I don't like it. I tested it against Toolstations Flag branded yacht varnish (which by the way smells very similar) and the yacht varnish was more resistant to marks and abrasions. It also went on a lot nicer. Thinned down to the same viscosity as the 'oil' I couldn't tell much difference between them so i used it thinned as a soak in undercoat. Anyway suffice it to say I sprayed the tops with the yacht varnish.

The underside with its raising mechanism and handle. yes those are open knot holes in the Oak but they are well sealed with varnish.

I added some mounting strips and enclosed the moving areas to keep out wandering hands under the table.

Underside view

And finally....

I couldn't face making a video of it in action so I took a series of pictures with the camera on a tripod and a cable release. Then I downloaded a trial of a easy gif animator program and made what you should see below.

It's a bit grainy as I tried to keep the file size down.

Chairs can wait till next year