The gear cutters are Thorntons - I was lucky they came with the Unimat.

It maybe worth considering buying ready cut pinions and wheel blanks from Ian Cobb because I think you need 3 different cutters?

Here's a pic of the overall pinion cutting using a dial gauge on the cross slide to check depth of cut:

Here's a filing rest I made to file the tiny flats on the Minute Hand/Hour Hand Bush:

This is two tubes - one inside the other and when made up gives this train (hands not connected yet)

The two files are in fact scraper/burnisher for polishing the brass.

Good luck

Rod

It maybe worth considering buying ready cut pinions and wheel blanks from Ian Cobb because I think you need 3 different cutters?

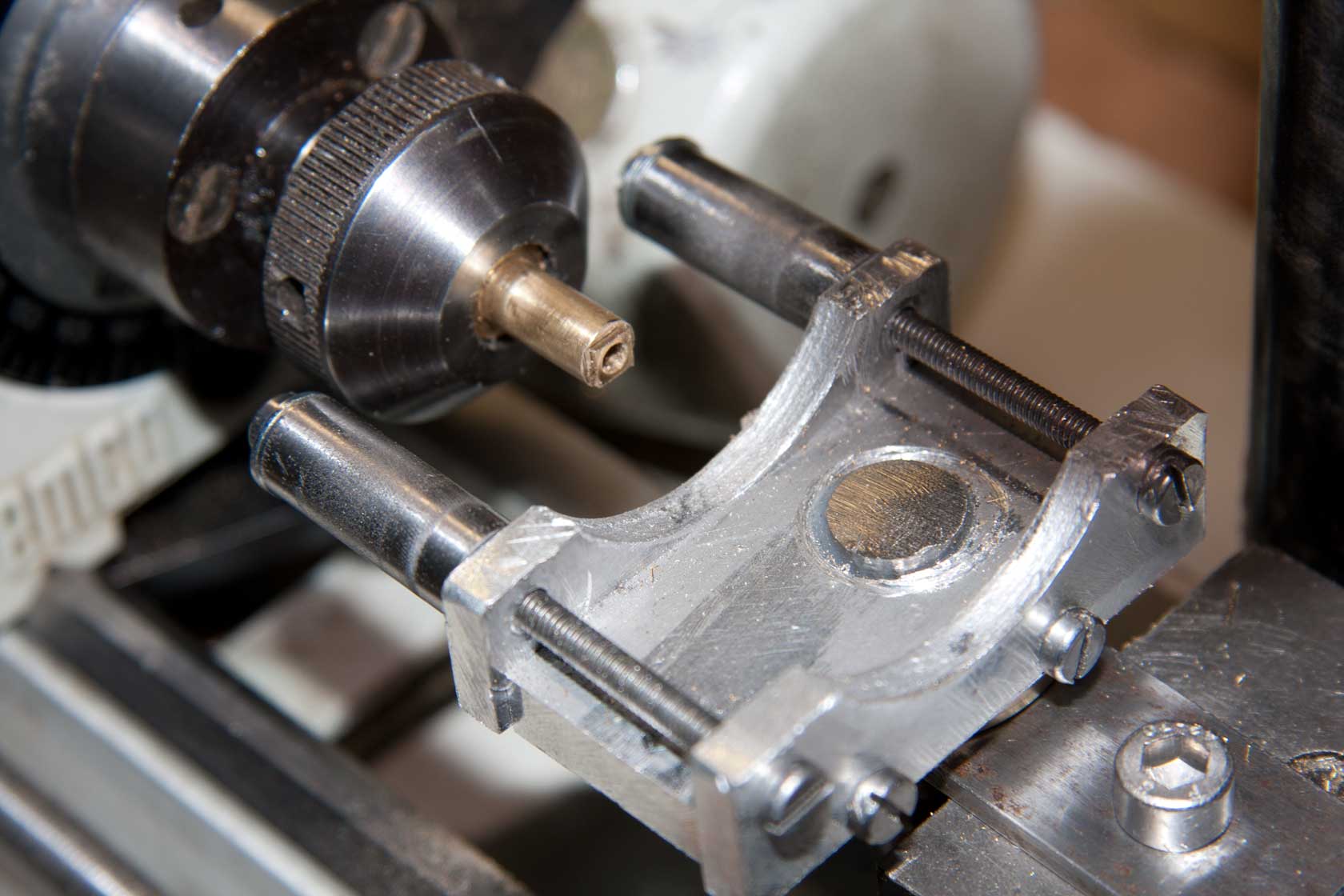

Here's a pic of the overall pinion cutting using a dial gauge on the cross slide to check depth of cut:

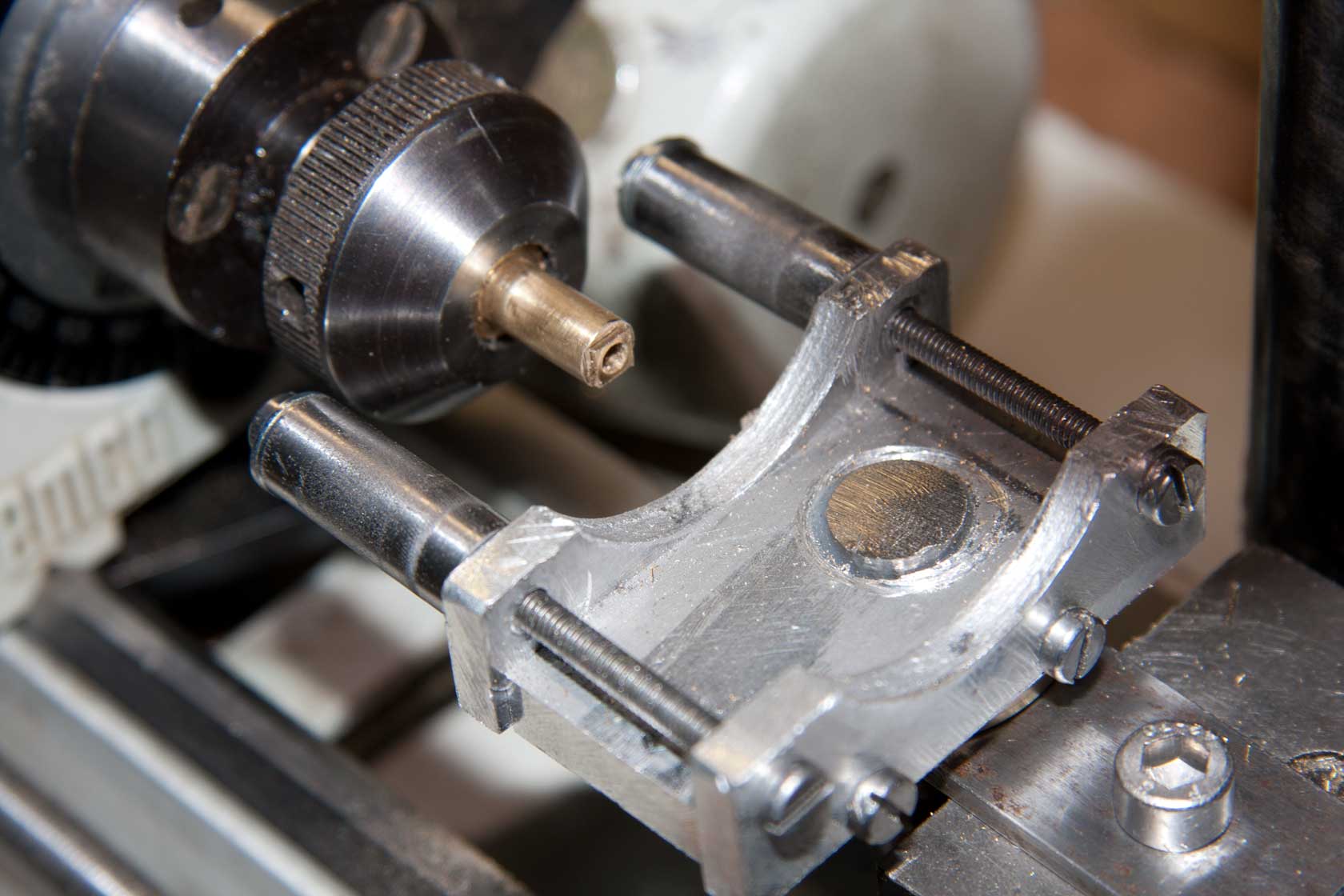

Here's a filing rest I made to file the tiny flats on the Minute Hand/Hour Hand Bush:

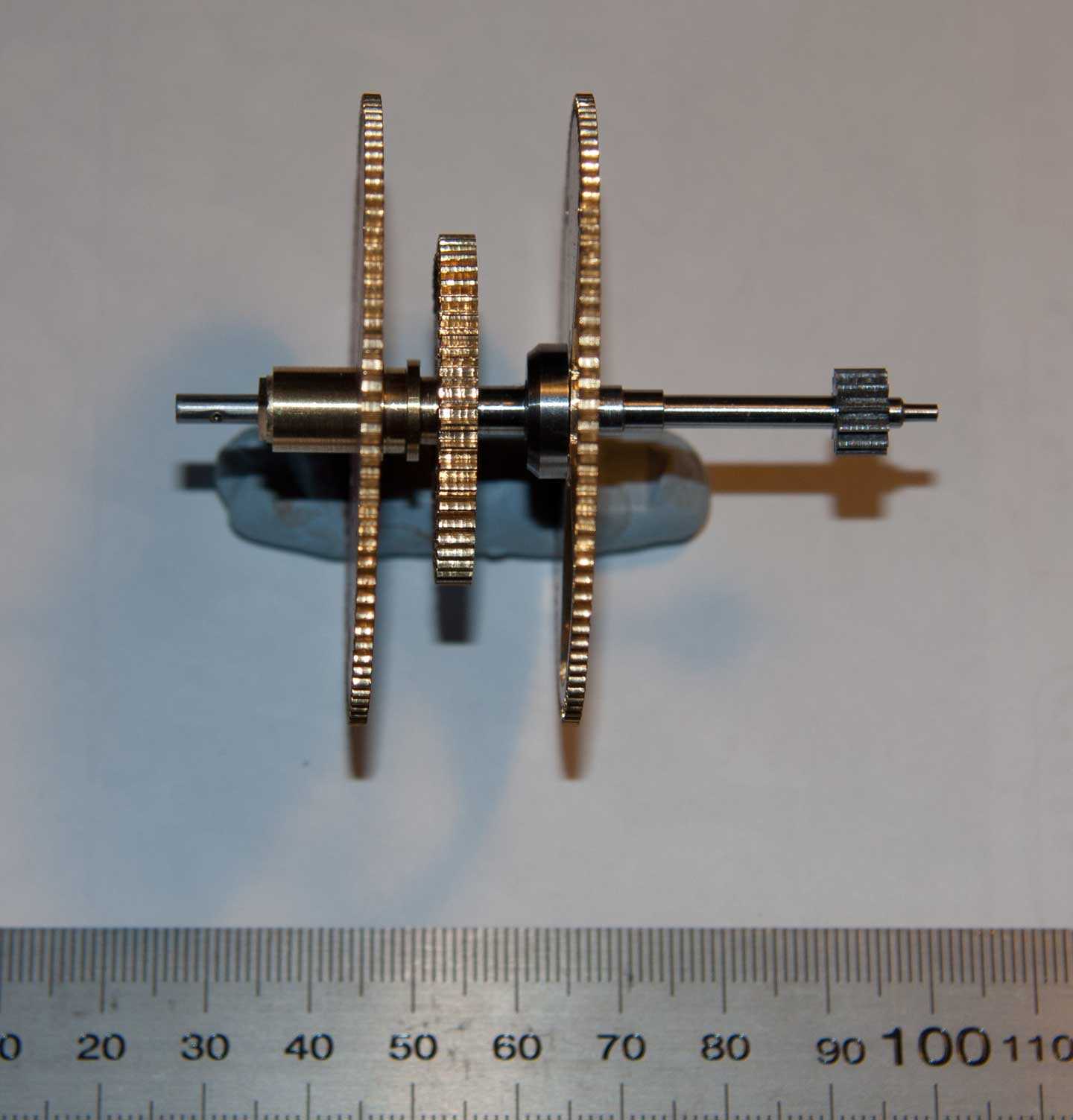

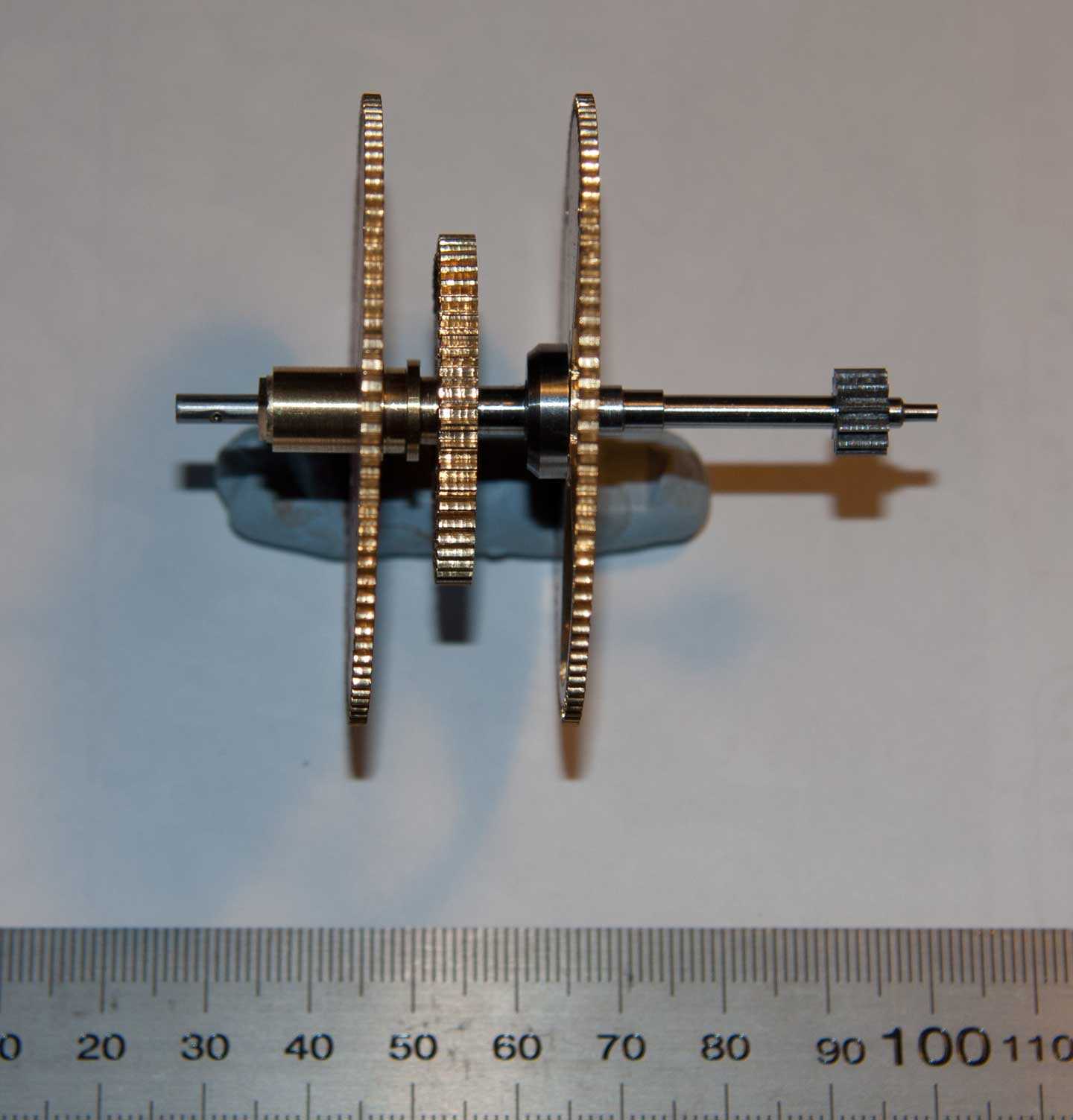

This is two tubes - one inside the other and when made up gives this train (hands not connected yet)

The two files are in fact scraper/burnisher for polishing the brass.

Good luck

Rod