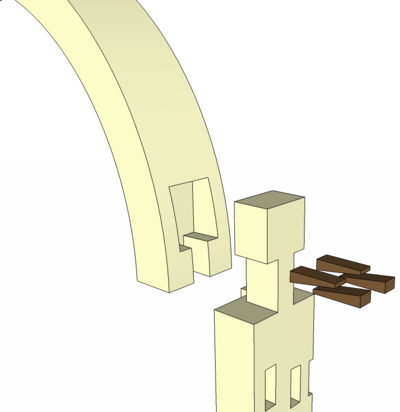

Wurm - for the glue blocks what they mean is something like this:

https://www.pinterest.co.uk/pin/176766354098993858/

There are two common types - reusable removable ones that are clamped to the work first then the angled clamp applied after, usually for repeated work.

The second is little more than a wedge that has been cut to a corresponding angle from the other angled face you wish to clamp and then glued onto the workpeice for clamping - once the clamping has been done and the glue dry - it's then cut and planed off.

In your case you take a sliding bevel and take a reading setting the body of the bevel so its sitting on the end of the arch mitre joint and angle the bevel part to match the average of the arch angle.

Then you get a bit of scrap large enough for your clamp head and cut it to that angle, and then glue it to the side of the door frame roughly in the middle - ensuring that the angled face you don't glue is the correct one and should be approximately parallel to the arch curve - also making sure it's not so low the clamp face can't reach it - you want to try to get the clamp face as close to the middle of the stock on both peices as possible or uneven pressure could lead to the inside glue joint being tight and the outside having a gap.

I'm not explaining it so well.... this might help you get the gist:

https://www.google.com/search?rlz=1C1AS ... APmd-2iA08

It is pretty straightforward... but remarkably complex to explain without a good reference !

Basically you're trying to make a block so that when the face of the clamp sits flat on the arch - it has a corresponding bit of wood on the side of the door stile opposite that matches the angle of the clamp face as it is presented.

Grab a clamp and put the bottom face roughly in the middle of the arch, then look at the top head and the angle of the clamp face in relation to the side of door stile - that's the angle you want to replicate in a block of scrap wood.

err hope that helps?