SkinnyB

Established Member

Wow! Didn't expect this kind of response.

To answer a few questions I read as reading through your posts:

Clamping was sufficient. 4 heavy duty F clamps.

I glued a 400mm section of Iroko onto the main upright then machined afterwards. Both surfaces were machined on the thicknesser.

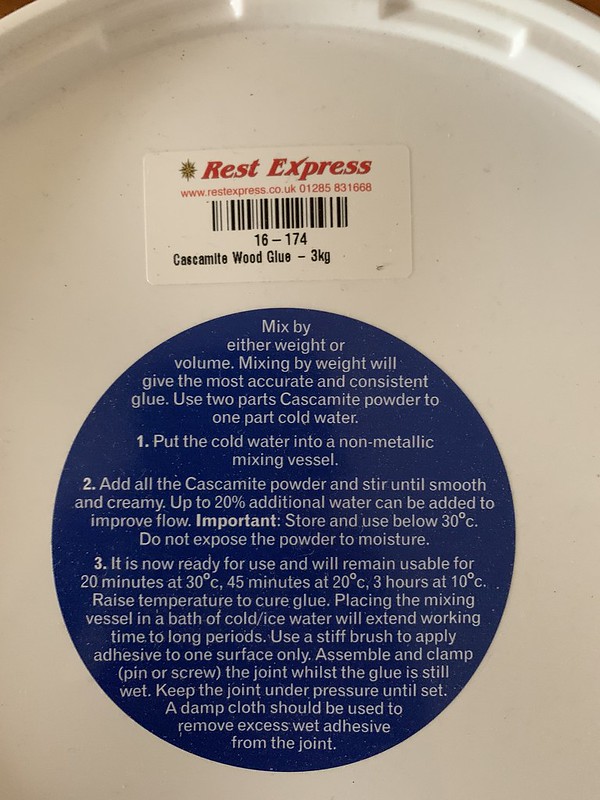

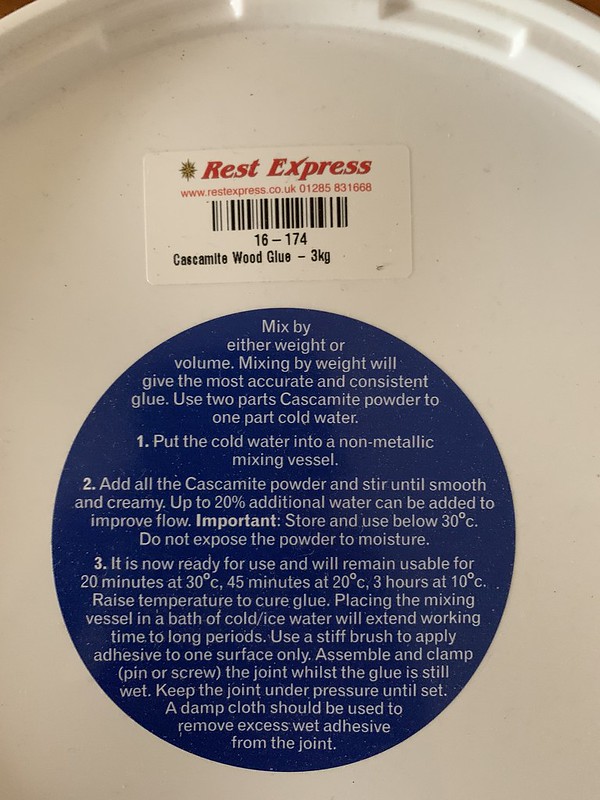

Glue was mixed to exact instructions as found on the bucket of Cascamite.

There was a good amount of squeeze out when clamped.

The wood was clamped at around 10c or a little less then brought inside the house. So this could be a factor.

Perhaps I should send some samples to Matthias Wandel for testing...

I will be sure to go with a doweled version next time to increase strength across this thinner section.

After discussion with my client and a previous company whom he had some bespoke Iroko windows off (who also said they had issues with Cascamite) we have decided to change glues.

Ill update once I know the brand. I think someone mentioned a red glue previously which is what I think it is.

Im getting a general feeling that Cascamite being a water based glue may not be the best glue. However I have used TB3 in the past with Teak/Iroko with success.

I think being an oily timber water based adhesives are not the way to go.

If I get time I will make up a few samples to of different glues and techniques.

Thanks for everyone input.

IMG_6780 by jamie skinner, on Flickr

IMG_6780 by jamie skinner, on Flickr

To answer a few questions I read as reading through your posts:

Clamping was sufficient. 4 heavy duty F clamps.

I glued a 400mm section of Iroko onto the main upright then machined afterwards. Both surfaces were machined on the thicknesser.

Glue was mixed to exact instructions as found on the bucket of Cascamite.

There was a good amount of squeeze out when clamped.

The wood was clamped at around 10c or a little less then brought inside the house. So this could be a factor.

Perhaps I should send some samples to Matthias Wandel for testing...

I will be sure to go with a doweled version next time to increase strength across this thinner section.

After discussion with my client and a previous company whom he had some bespoke Iroko windows off (who also said they had issues with Cascamite) we have decided to change glues.

Ill update once I know the brand. I think someone mentioned a red glue previously which is what I think it is.

Im getting a general feeling that Cascamite being a water based glue may not be the best glue. However I have used TB3 in the past with Teak/Iroko with success.

I think being an oily timber water based adhesives are not the way to go.

If I get time I will make up a few samples to of different glues and techniques.

Thanks for everyone input.

IMG_6780 by jamie skinner, on Flickr

IMG_6780 by jamie skinner, on Flickr