LuptonM

Established Member

Move over James May, you have nothing on me. How long would it take to make a shooting board. An hour perhaps. Not me, I've already probably taken about 4 hours over a couple of days and I am not quite finished!!!

I just have to make the bottom hook and finish applying some tung oil that I think has a best before date of 2001 and has been open for at least 5 years. I guess once finished I'll have to work out how to use the damn thing. I've noticed the sides of plywood don't respond well to hand planing- can't really get it smooth

Sort of a mock up below;

It taken a fair while mainly cos I've cut it to dimensions with a builders diy saw, and my sawing technique is pretty rough. This means it takes a while for me to get the cut surface smooth and flat.

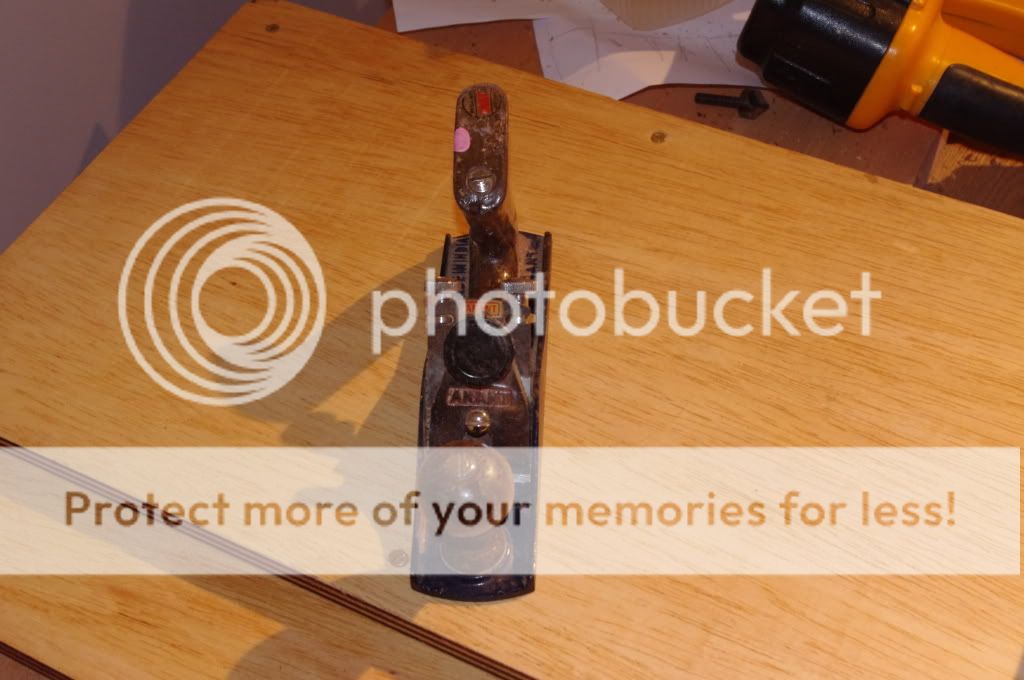

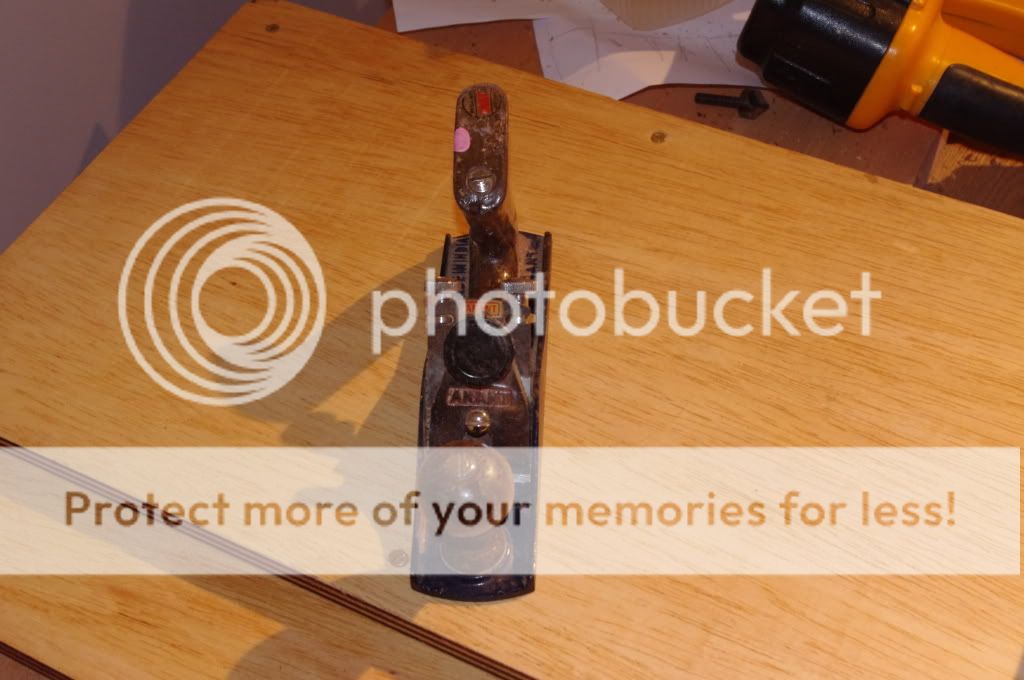

I am using my dad's pride and joy (cough cough), an anant no.3 smoother as a-kind-of-scrub plane- pictured below to get the surfaces sort-of flat

Workspace ain't to great to be honest. My workbench is sort of in the kitchen. My parent have decided that their shoe box of a kitchen isn't big enough and have knocked down the wall in between it and the 'spare room'. So lots of junk is sort of collecting round my bench while they do some work. My workbench was supposed to be in the garage but my grandfather (one of 2) has moved into a nursing home and my parents are having to sell his flat in order to fund his care, so all his unwanted possessions are occupying the garage for the time being.

I just have to make the bottom hook and finish applying some tung oil that I think has a best before date of 2001 and has been open for at least 5 years. I guess once finished I'll have to work out how to use the damn thing. I've noticed the sides of plywood don't respond well to hand planing- can't really get it smooth

Sort of a mock up below;

It taken a fair while mainly cos I've cut it to dimensions with a builders diy saw, and my sawing technique is pretty rough. This means it takes a while for me to get the cut surface smooth and flat.

I am using my dad's pride and joy (cough cough), an anant no.3 smoother as a-kind-of-scrub plane- pictured below to get the surfaces sort-of flat

Workspace ain't to great to be honest. My workbench is sort of in the kitchen. My parent have decided that their shoe box of a kitchen isn't big enough and have knocked down the wall in between it and the 'spare room'. So lots of junk is sort of collecting round my bench while they do some work. My workbench was supposed to be in the garage but my grandfather (one of 2) has moved into a nursing home and my parents are having to sell his flat in order to fund his care, so all his unwanted possessions are occupying the garage for the time being.