You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

canvas stretcher frame joint

- Thread starter Woodmonkey

- Start date

Help Support UKworkshop.co.uk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Brentingby

Established Member

Looks like that one was made on the tablesaw. Steve Maskery's Ultimate Tablesaw Tenon Jig would be an excellent tool for this.

Sgian Dubh

Established Member

A year or two back we did some research on working these joints and discovered there are machines dedicated solely to cutting them, intended no doubt for workshops that had enough stretcher bar work to make buying a machine viable. Here's a link to one machine manufacturer: http://www.stegherr.net/en/picture-fram ... e-brf.htmlBrentingby":1msvenog said:Looks like that one was made on the tablesaw. Steve Maskery's Ultimate Tablesaw Tenon Jig would be an excellent tool for this.

The alternative we came up with was to use a dedicated sawblade and moulder blocks all on the spindle moulder, but it would have involved four set ups which is time consuming.

I think for a one off, if that's what woodmonkey's asking about, the most likely approach I'd take would be with the spindle moulder, much as described above. It would have to be that or go with a largely hand worked approach that might include routers and jigs. Lastly, these stretcher bars are pretty economical to buy, even at a custom size from artists suppliers, and that might be a reasonable way to go, which would save a lot of time faffing about until the methodology is worked out. Slainte.

Once you open up the joint with the wedges, to stretch the canvas, the mitre isn't doing anything.

You could get the same effect with a plain tenon and slot mortice joint, with slender wedges working against the side of the tenon in one direction and the shoulders in the other direction.

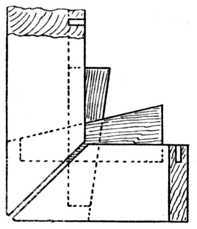

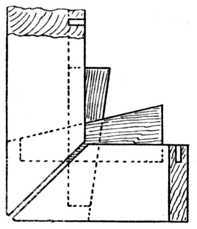

Alternatively, there is a variant in which the two grooves are run straight through, and the ends cut off with a simple mitre through the whole thickness of the wood. Tapered wedges fit into the slots across two pieces, holding the corners together in the plane of the picture while wedging it apart in the other directions.

These just need through grooves (table saw, router or plough plane, whichever you prefer) with a little bit of angle cutting at the ends, which could easily be done with a narrow chisel or a wide saw.

A diagram makes it clearer!

(From William Fairham's book on Woodwork Joints, available here and elsewhere.

You could get the same effect with a plain tenon and slot mortice joint, with slender wedges working against the side of the tenon in one direction and the shoulders in the other direction.

Alternatively, there is a variant in which the two grooves are run straight through, and the ends cut off with a simple mitre through the whole thickness of the wood. Tapered wedges fit into the slots across two pieces, holding the corners together in the plane of the picture while wedging it apart in the other directions.

These just need through grooves (table saw, router or plough plane, whichever you prefer) with a little bit of angle cutting at the ends, which could easily be done with a narrow chisel or a wide saw.

A diagram makes it clearer!

(From William Fairham's book on Woodwork Joints, available here and elsewhere.

Woodmonkey

Established Member

Thanks fellas. I was asked by an artist friend if I could price up making a few for him, he was complaining of the cost to buy them (typically skint artist I guess). Sounds like i would struggle to make them for less than a supplier with a dedicated machine. I don't have a spindle moulder.

They're made on a shaper using cutters that work a bit like a cope and stick bit - I worked for company where we used thousands of stretcher bars a year and we looked into making them but it was too much cost to be worth it as they can be made in China for beans

£49.91

£58.33

Mefape Mortise and Tenon Jig Tools for Woodworking Routers, Tenon Cutter, Manual Mortising Machine, Invisible Slotting Machine Jig Stand, 3-Axis Guide Rail for Adjust Trimming Length and Width

wangshijuntianjinhongyuegongyipin

£10.10

£15.48

Portwest Browguard with Clear Visor, Size: One Size, Colour: Clear, PW91CLR

Amazon.co.uk

£34.99 (£3.50 / count)

£39.99 (£4.00 / count)

VonHaus Chisel Set - 10pcs Woodworking Tools Set - Wood Carving Tools, Wood Chisel Sets with Sharpening Stone, Honing Guide and Storage Case

VonHaus UK

£15.99 (£1.60 / count)

£27.44 (£2.74 / count)

3M 8822 Disposable-fine dust mask FFP2 (10-pack)

Amazon.co.uk

£10.19 (£0.39 / count)

£11.99 (£0.46 / count)

Nicpro Carpenter Pencil with Sharpener, Mechanical Carpenter Pencils Set with 26 Refills, Case, Deep Hole Marker Construction Pencils Heavy Duty Woodworking Pencils for Architect (Black, Red)

NicproShop EU

£9.99 (£1.00 / count)

£14.45 (£1.44 / count)

JSP M632 FFP3moulded Disposable Dustmask (Box of 10) One Size suitable for Construction, DIY, Industrial, Sanding, dust protection 99 Percent particle filtration Conforms and Complies to EN 149

Amazon.co.uk

£16.99

£19.99

Respirator Mask,Safety Dust Face Cover,Dust Face Cover Paint Face Cover,Gas Mask With Filter,For Paint,Dust And Formaldehyde,Sanding,Polishing,Spraying And Other Work

ShenZHEN CIRY MINGYANG LITIAN ELECTRONIC ECOMMERCE

£199.00

£360.17

Trend Portable Benchtop Router Table with Robust Construction for Workshop & Site Use, 240V, CRT/MK3

Amazon.co.uk

£24.99

Facemoon Reusable Masks,Safety Masks,Dual Filter Masks, Paint, Dust, Epoxy Resin, Construction, Welding, Sanding, Woodworking, Chemical Reusable Gas Masks

ShenZHEN CIRY MINGYANG LITIAN ELECTRONIC ECOMMERCE

Sgian Dubh

Established Member

You almost certainly wouldn't get close to matching the price of mass produced standard size stretchers unless you're willing to work for peanuts and, as I said earlier, even custom size stretcher bars aren't overpriced, or at least that how it seems to me. Slainte.Woodmonkey":10r2a6gf said:Sounds like i would struggle to make them for less than a supplier with a dedicated machine.

Steve Maskery

Established Member

Whilst I am very grateful for Brentingby's endorsement of the UTTJ, even I would acknowledge that it would be quite a job to build it just for this task. Sure, it could be used for it, and the results would be excellent, you would just need to do the mitres, but it's probably only worth building the jig if you plan to use your TS for tenon work generally.

S

S

woodchip

Established Member

I pay around £4 for a pair of bars (so £8 a frame), including wedges, so I really don't think it's worth trying to make them yourself. Leave it to the mass producers.

Similar threads

- Replies

- 9

- Views

- 750

- Replies

- 4

- Views

- 497

- Replies

- 6

- Views

- 223