I completed the Lingerie Chest this weekend, and moved it to our bedroom to recuperate from the cold of the workshop.

It was comforting to see the pieces still looking quite good …

Here it is in the nook that was always to be its home.

What I would like to share with you are the details that I have been working on over the past few weeks. These have been fun to do, especially as they were planned right at the outset, but left until the end.

The first task was not so fun, if I am honest. In fact I wanted to avoid the risk I needed to take, and enquired of a few people whether they could spot the problem. I was reminded that, if you have to ask, then there is an issue. What was the issue? It lay with the fitting of the handles.

Here is an older picture of the drawers taken after the handles were fitted ..

What is difficult to see is that the drawers are bowed, while the handles are designed for a flat drawer face. As a result, there are gaps at each end …

I dreaded having to chisel into the drawers to seat the handles. In the end, I knew I could not leave them like this. Fortunately I came up with an alternate plan, which was to file the raised sections of the handle into a profile that matched to drawer fronts.

To do this I build a profile of the bow, taped on 120 grit sandpaper, and lapped the handles on this …

Despite fantasies of the handles disintegrating, it turned out all good.

The second area involved the “jewelry drawer”.

Facing the chest (48” high), my wife is tall enough to look down into the top drawer.

Since this drawer is to hold jewelry, it needed to be locked. I did not wish to add more hardware than necessary and so, instead of a lock-and-key, added a Quaker Lock.

A Quaker lock is simply a spring-loaded wedge under the drawer. It is made of the following parts: thin, flexible (straight-grained) strip of wood, a thin wedge, and screws …

These are put together to create a spring wedge, which extends to the rear of the drawer blade ..

To release the Quaker lock, first open the second drawer, then reach underneath and push up the spring while simultaneously pulling out the drawer.

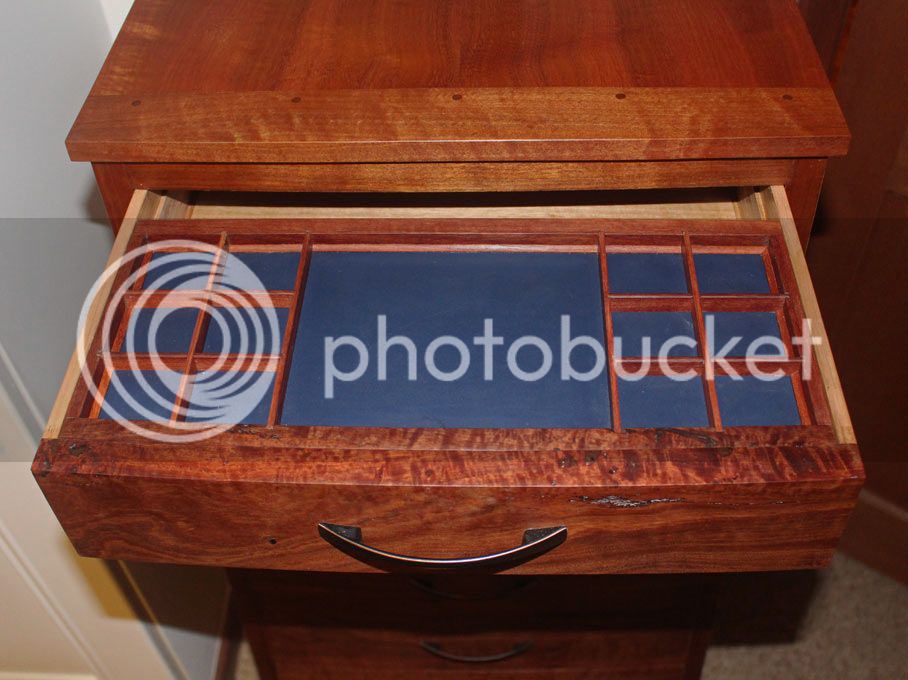

The top drawer opens to reveal the upper jewelry tray (spaces for ear rings) …

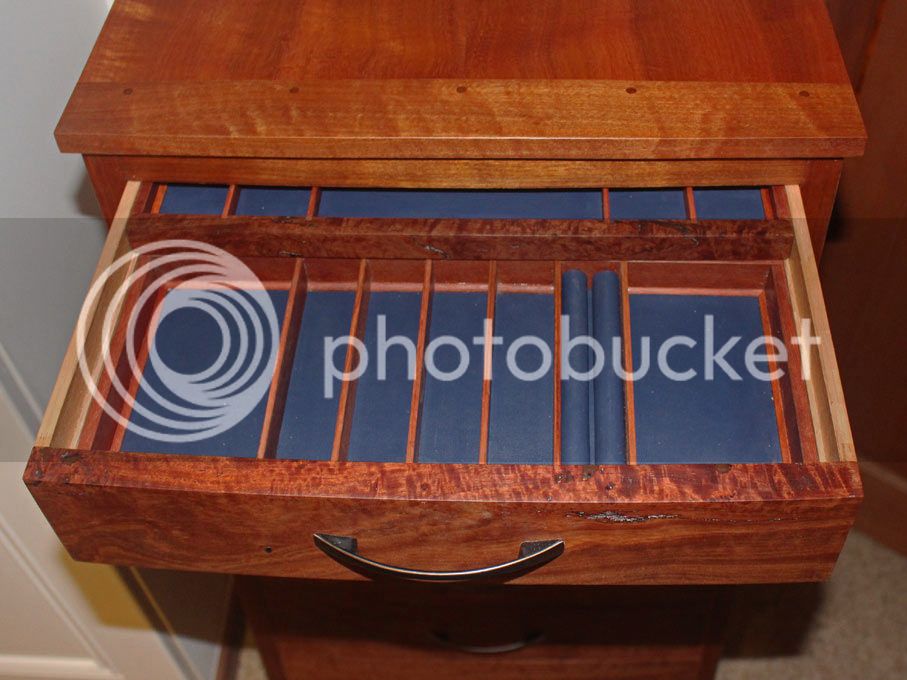

Sliding it back reveals the lower jewelry tray (spaces for necklaces and rings) ..

The construction of these trays was based on a different design to the drawers. Slips were used in the drawers, but the trays needed to maximize the space inside, which left the 3mm (1/8”) thick drawer bottoms 3mm from the lower edge.

As can be seen below, the lower pin is not enclosed, which allows more space for the drawer bottom groove ..

The drawer bottoms were covered in 1.2mm thick leather. This was attached with contact glue (I used a brand that permitted some movement for repositioning up to 3 minutes after placement). The edges were tidied up with coved beading.

That coved beading was a real bugger to make and fit as it was so tiny. The drawers were for the most part easy to fit. However, the compound curves behind the drawer fronts and at the top of the mirror (which curves to match the bow drawers) required extra attention.

The jewelry trays are easy to lift out of the drawer. The idea for fitting them came from the sliding tills in tool chests. To do this with these drawers, the inside of the drawer sides was squared up with filler pieces. To ensure that the lower drawer does not slide away from the front position, clips were added to the rear (they are shelf rests and just push into the sides). These can be removed if needed. There is now hidden space behind the lower tray.

The third area involves the mirror recess. This was also covered in leather …

Here is one example of the coved beading around the mirror (so difficult to photograph owing to the reflections) ..

And so we come to the end of this build. All-in-all, it stretched over 18 months (closer to 14 months of actual build time on weekends), which is my longest project to date.

Thanks for looking.

Regards from Perth

Derek