steamboat

Established Member

Hello all. I have a woodworking predicament I need advice with.

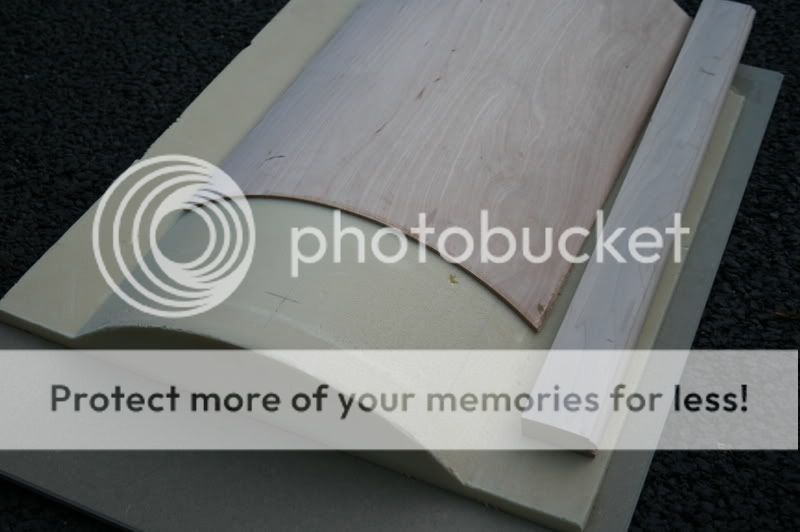

I am making a pair of loudspeakers and want curved sides. I am using 4m plywood eventually laminated together over a former to get the shape I need. Unfortunately as you can see from the pictures the wood is not conforming to the shape evenly over the entire length and the edges are wavy, which is obviously no good as the sides need to be very accurate. Has anyone got any suggestions from their own experiences?

Any help welcome

sorry cant work out how to add pictures [/img]

[/img]

I am making a pair of loudspeakers and want curved sides. I am using 4m plywood eventually laminated together over a former to get the shape I need. Unfortunately as you can see from the pictures the wood is not conforming to the shape evenly over the entire length and the edges are wavy, which is obviously no good as the sides need to be very accurate. Has anyone got any suggestions from their own experiences?

Any help welcome

sorry cant work out how to add pictures