Last time on, Bandsaw SOS.

Ohhh you sod you!... :roll:

And now, the conclusion...

Once I had regained my composure, and sobriety, I went back to the machine.

The tyre had completely come off. It looks like it wasn't stuck down sufficiently first time round.

I remove the wheel and strip it with Nitro Mors and a wire brush and sand the outer mating surface to get the old glue residue off.

Then give it a coat of lubricating wax and refit it.

I then spend the best part of an hour fitting the tyre, checking the crown, removing the tyre, rotating it an inch, refitting and retesting.

The crown of the tyre *was* perfect despite the wheel being deformed and I wanted that back as close as I could get.

Eventually I get the point of best fit and mark the tire and wheel in several places so I could refit it in exactly the right place once the glue was on it.

I bought some evo stick (the type that allows some repositioning) and applied a thin coat to the tyre and wheel and left it to dry off.

Then a had to get it back on the wheel. The glue only allows repositioning if you don't apply pressure to the glued surfaces. How can you fit a tyre with now pressure? You can't, so I had to get it right first time.

No pictures of this as I was too busy getting the good fit back before the glue stuck fast. It went ok, I could reposition the tyre very slightly. I just had to get it fairly close first time round. The glue takes 24 hours to cure so that's what it got.

I reassembled the wheels and fitted the blade again and re-ran my unguarded test from the other end of the shop and the tyre held! WOOW!

Excited by my success I just started bolting the machine back together. And that is the end of the story. The machine is back together and works!

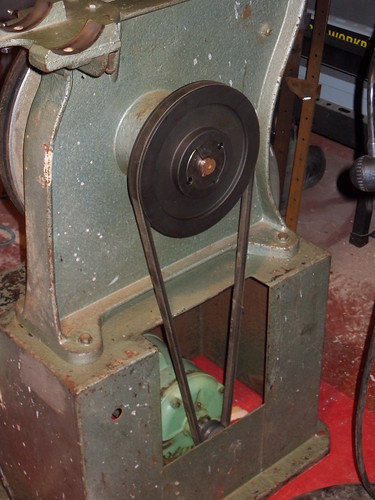

A shot from the back, note the missing upper-rear blade guard. I'll have to come up with something for that.

The table is as good as new!

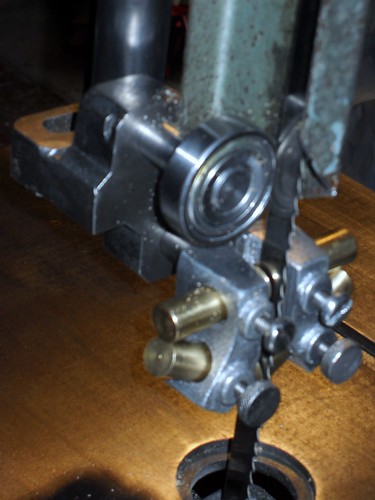

Top and bottom blade guides fitted and adjusted (nearly, they are not quite close enough yet)

Ignore the scattered clutter!

And the most important question : How good is it?

This is some inch oak I had knocking around.

Even with the fairly old and abused blade fitted it made short work of this. Slight burning on one side. I figure that is my lack of technique for now. Higher feed rate on the second piece eliminated the burning.

I think a new blade will get ordered soon.

So, how much has all this lot set me back? Was it worth it?

The saw, bearings for the top wheel, bearings for the blade guards, the pulley & taper bush, new grease, three bearing pullers, a tin of nitro mors, a tin of lubricating wax, glue and two wire wheels. Roughly £155.

Yes, it was worth it! :lol:

There is more I could do. It could do with repainting to be honest but I'll leave that until something else needs to be done. For now I want to get on with woodwork as opposed to machine restoration.

There is, however, the little matter of the Walker Turner floor standing drill press that is sat next to the saw... :lol:

Thankyou to everyone who has given advice or encouragement, it has been a very rewarding experience getting this chunk of cast iron back into shape.

Cheers.

Pete