More progress...

I decided to clean off the old green paint from the hub. I used an old drill with a wire wheel and spent 40 minutes getting all the paint off all off the hub components. This was my setup. I used my vice to hold each piece, cleaned them up and washed the grease off in the sink. Then gave them a good coat of lubricating wax to keep them relatively shiney.

Once everything was coated I went down to the local car place and bought some new grease.

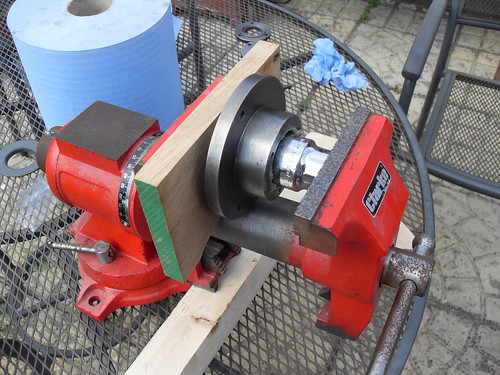

I gave the mating services in the hub a good coat and got the vice setup as shown. The bearings have been in the freezer since thursday! So, I got the setup ready, made sure the hub was ready and I had a correctly sized socket to act as a pushing block. Then I went to get the first bearing out of the freezer. I open the packet and quickly daube a load of grease all over it to keep the air away from it. Then put everything into the vice and press it in. It worked perfectly first time, a very nice controlled press. 30 seconds and it was done.

Next I placed the spacer into the hub, from the other side, and held it in place with a load of grease all around.

You can see the spacer here being held in the correct position by the grease.

Then I put the second bearing in. This was slightly more difficult than the first one. I used the same procedure but it just wouldn't begin to seat evenly. I ended up tapping the bearing in with a small hammer for the first 1-2mm. This worked fine and I only used the hammer until the bearing was on it's way. Then it was pressed in with the vice as per the first one.

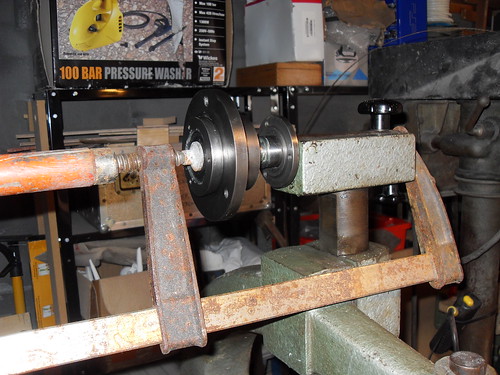

Once the hub was together I had to press it onto the shaft. I cleaned up the shaft and gave it a good coat of grease. I offered up the hub and helpfully it would go on about 2 mm just from hand pressure.

Once it was started I could get my "bearing presser" into place. This you will notice is just an old rusty clamp. I was going to use one of my largest record G-Clamps but its foot was too large for the bearing and the socket was too large to fit in the clamp. So I used this instead. The foot is the perfect size for the inner race.

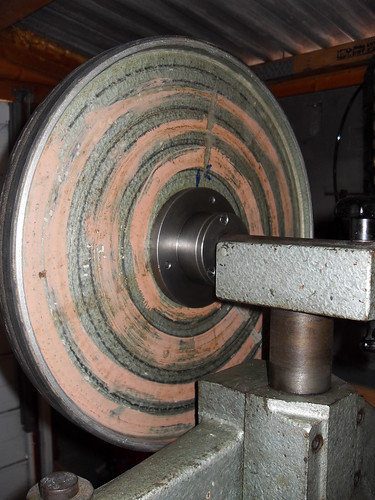

Once the hub was on it remounted the wheel and here it is in all it's glory!

It *still* doesn't spin for as long as the bottom wheel but it is completely silent! I can't hear it at all. Lovely.

So, all in all it was pretty easy to do and I like the bare metal finish. I'll have to keep an eye on it and it'll nead a coat of wax every now and then but it's done!

On to the next issue. The rattly motor mount!

Thanks all

Pete