Mr Ed

Established Member

As discussed in other threads I am weighing up the options on new (larger) bandsaws. I am interested to know peoples opinions / preferences on the type of guide.

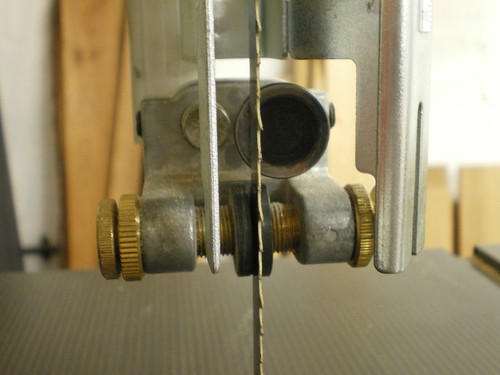

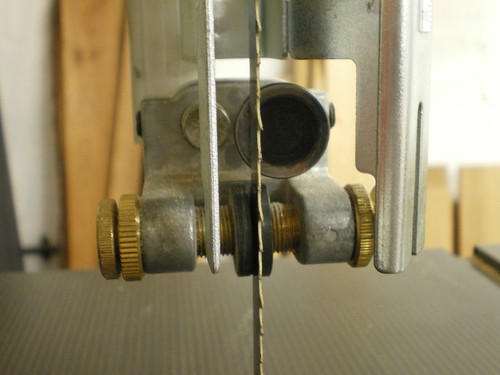

Currently I have this type on my Scheppach Basato 3;

I don't get on particularly well with these and think the type with the bearings at 90 degrees to this would be better. They seem to me to support the blade better and stand more chance of rotating effectively with the blades movement.

I know David Charlesworth swears by his lignum vitae blocks, which is not something I have tried. In this same veign are ceramic and other composite material blocks, which seem more popular in the US.

I see the guide system as a key part of the machines accuracy and therefore significant in the selection of a machine. What does anybody think?

Cheers, Ed

Currently I have this type on my Scheppach Basato 3;

I don't get on particularly well with these and think the type with the bearings at 90 degrees to this would be better. They seem to me to support the blade better and stand more chance of rotating effectively with the blades movement.

I know David Charlesworth swears by his lignum vitae blocks, which is not something I have tried. In this same veign are ceramic and other composite material blocks, which seem more popular in the US.

I see the guide system as a key part of the machines accuracy and therefore significant in the selection of a machine. What does anybody think?

Cheers, Ed