apj101

Member

- Joined

- 27 Aug 2008

- Messages

- 16

- Reaction score

- 0

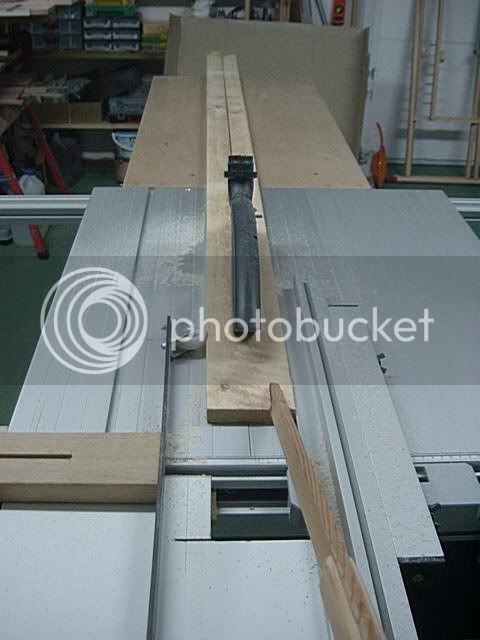

Morning folks, I bought a axminster ts200 at the weekend, decent saw for the price point (although probably too big far my little shop  )

)

Recall a few people on this site have this saw and wanted to ask a few questions.

The table fence isn’t really long enough, it only goes about 1/3 – ½ the length of the table and therefore doesn’t clear the saw blade, while good to prevent kick back it makes the final few cm’s a pain to cut as there is little support……how did/would you chaps go about fixing this, could fit a sacrificial fence that is longer than the existing fence, but not sure how to do that and ensure squareness. Plus a perm sacrificial fence would permanently throw out my ruler on the sliding arm.

Also there is no bloody adjustment on the fence to square it up! Fortunately its pretty square at the moment, but cant be sure it will stay that way, especially if I put a sacrificial fence on it. Any thoughts?

Overall im happy with the saw, but keen to see comments on the fence issues.

Recall a few people on this site have this saw and wanted to ask a few questions.

The table fence isn’t really long enough, it only goes about 1/3 – ½ the length of the table and therefore doesn’t clear the saw blade, while good to prevent kick back it makes the final few cm’s a pain to cut as there is little support……how did/would you chaps go about fixing this, could fit a sacrificial fence that is longer than the existing fence, but not sure how to do that and ensure squareness. Plus a perm sacrificial fence would permanently throw out my ruler on the sliding arm.

Also there is no bloody adjustment on the fence to square it up! Fortunately its pretty square at the moment, but cant be sure it will stay that way, especially if I put a sacrificial fence on it. Any thoughts?

Overall im happy with the saw, but keen to see comments on the fence issues.