bugbear

Established Member

My guttering down pipe has come away from the wall, because

the old wall plugs have just dried out.

Does anyone have an old carpentry book giving instruction

in this old fashioned way of fixing "stuff" to walls?

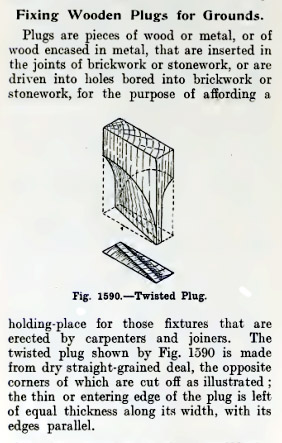

I know you use an axe to shape a block with a twist, so that

as it is hammered into a rectangular hole, tension

is created.

But I would appreciate info on sizes, amount of twist,

chosen timber etc (and, of course, the "unknown unknowns"... )

BugBear

the old wall plugs have just dried out.

Does anyone have an old carpentry book giving instruction

in this old fashioned way of fixing "stuff" to walls?

I know you use an axe to shape a block with a twist, so that

as it is hammered into a rectangular hole, tension

is created.

But I would appreciate info on sizes, amount of twist,

chosen timber etc (and, of course, the "unknown unknowns"... )

BugBear