MikeG.

Established Member

It doesn't need to be ply. OSB is much cheaper, and is the standard board used in these circumstances these days.

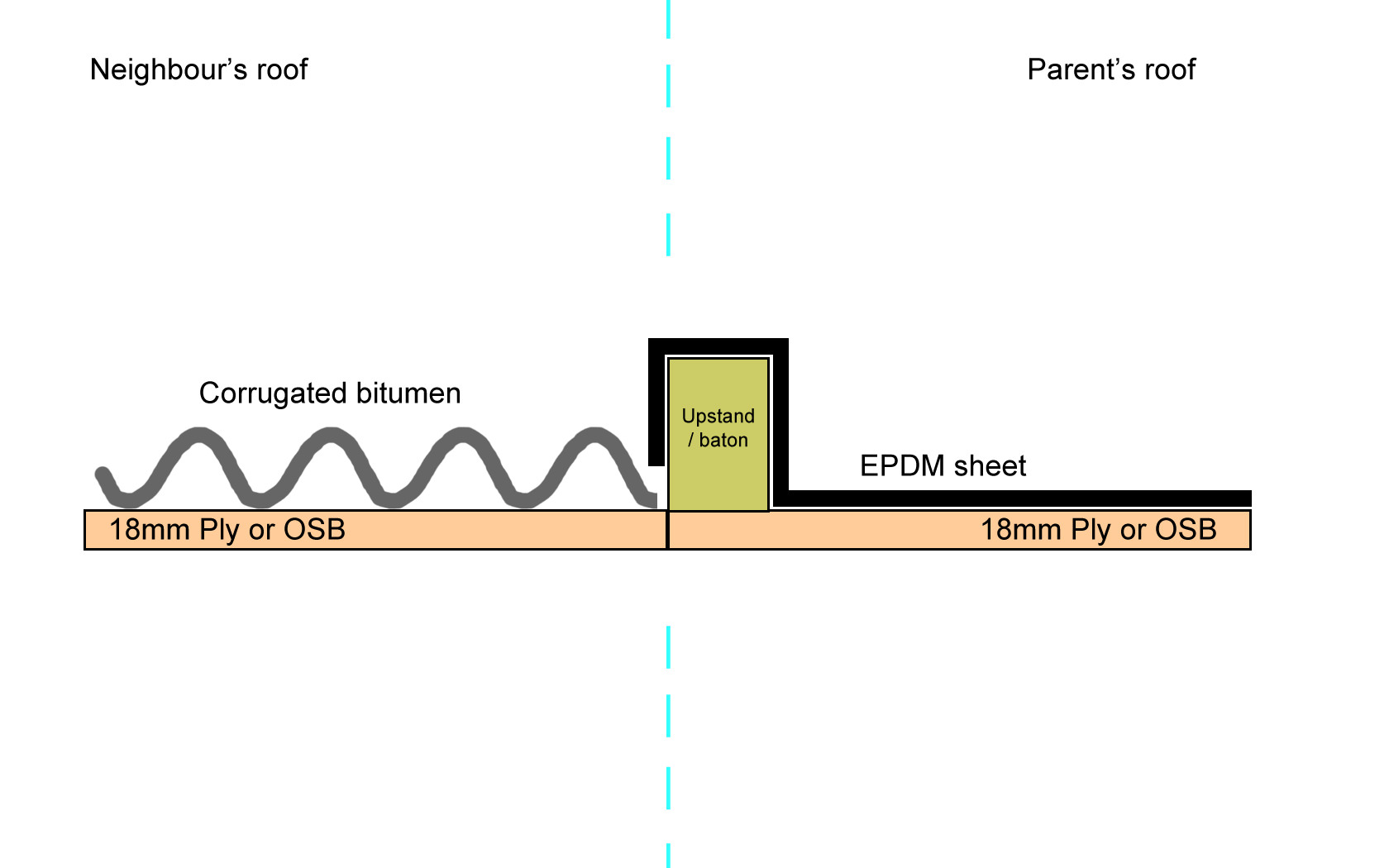

MikeG.":ccdpteei said:You need a flashing over the corrugated roof, or, indeed, under it, and terminating at the top of the upstand. Then you need to dress your EPDM over the upstand and over the top of that flashing, and down over its face. Given that EPDM won't glue to the flashing, you'll need to fix a piece of timber over the top-most part of the flashing, level with the top of your upstand, and fix your EPDM to that, with their proprietry plastic moulding. You should form a drip of the EPDM by doubling it up, such that water drips off it without getting into contact with your second piece of wood.

MikeG.":3w5bzfpk said:I think that the corrugated roof looks like a bitumen-impregnated product such as Onduline. I don't think you'll get anything to stick to that for long. However, they do their own proprietry flashing, which also doubles as a ridge and verge board. You'd have to cut it down to the height of your timber upstand (and the stuff is murder to cut..........it will cost you a saw), but I think it's probably your best bet. You should make that timber upstand as big as you possibly can.........at least 100x50 on edge, and better still if it was 150x50. You'll need to fasten it down very securely.