DBT85

Established Member

Stop the drill press!!!

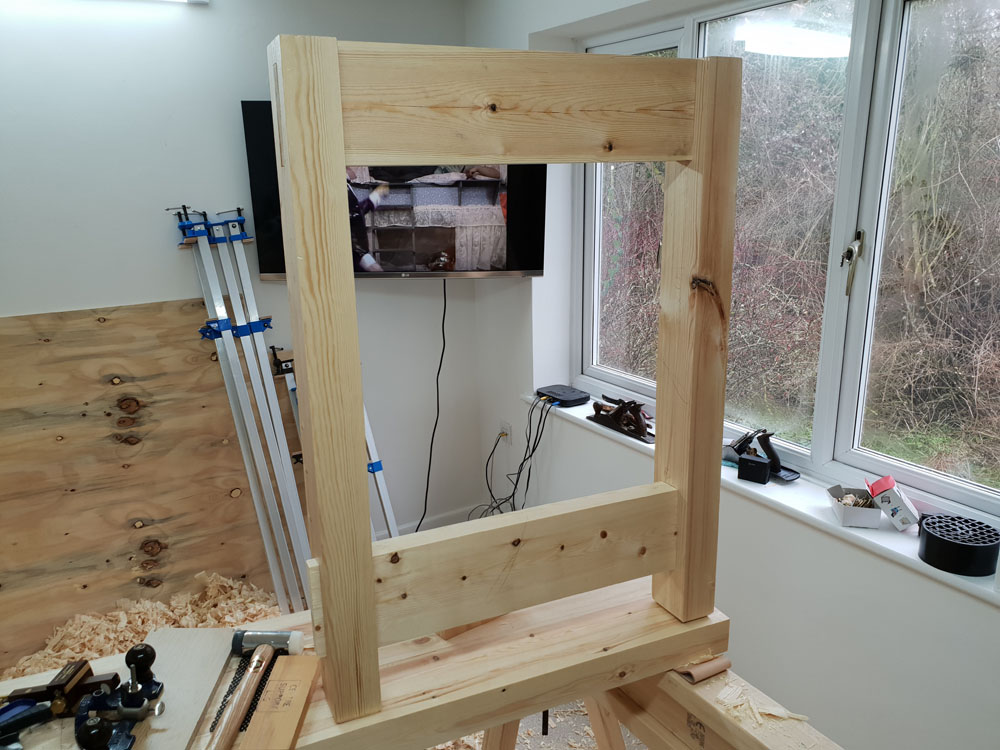

I have, at long last, started joinery!

I finally got around to getting one end of each leg square, then got my legs cut to length at 900mm and took the corners off the ends that'll be on the floor.

From there I started marking up my first leg, making notes for myself to help when I do the other 3. This first leg is going to be for the face vice end, so the top rail will sit flush with the top of the leg.

The legs for the other end will have the rail dropped 50mm to allow the bars for an end vice to pass through.

Like NickN, I went with a 24mm mortise rather than the speced 18mm. Just looked weedy by comparison.

First pass down the mortise complete. Not too shabby for a first attempt. Probably took too large a bite from time to time.

Got all the way through quite readily, then cleaned up and cut the haunch.

And last but not least, some nice waste.

My Lidl chisel is holding its edge nicely so I'm wondering if the one Nick had issue with was just a bad batch?

Have to say it went quicker than I expected for my first go. I was being very careful not to wander from my lines. Very pleased with the result though!

Anyway, I got 1/4 of the way through the other mortise before baby bedtime put paid to my efforts as i'm in the room next door! As of Wednesday I've got a lot of time to get going so hopefully I can make more progress. It was so satisfying finally doing something other than planing!

I have, at long last, started joinery!

I finally got around to getting one end of each leg square, then got my legs cut to length at 900mm and took the corners off the ends that'll be on the floor.

From there I started marking up my first leg, making notes for myself to help when I do the other 3. This first leg is going to be for the face vice end, so the top rail will sit flush with the top of the leg.

The legs for the other end will have the rail dropped 50mm to allow the bars for an end vice to pass through.

Like NickN, I went with a 24mm mortise rather than the speced 18mm. Just looked weedy by comparison.

First pass down the mortise complete. Not too shabby for a first attempt. Probably took too large a bite from time to time.

Got all the way through quite readily, then cleaned up and cut the haunch.

And last but not least, some nice waste.

My Lidl chisel is holding its edge nicely so I'm wondering if the one Nick had issue with was just a bad batch?

Have to say it went quicker than I expected for my first go. I was being very careful not to wander from my lines. Very pleased with the result though!

Anyway, I got 1/4 of the way through the other mortise before baby bedtime put paid to my efforts as i'm in the room next door! As of Wednesday I've got a lot of time to get going so hopefully I can make more progress. It was so satisfying finally doing something other than planing!