What with several trips abroad and Grand-parenting duties I have not had much time in the Shop over the last few months:

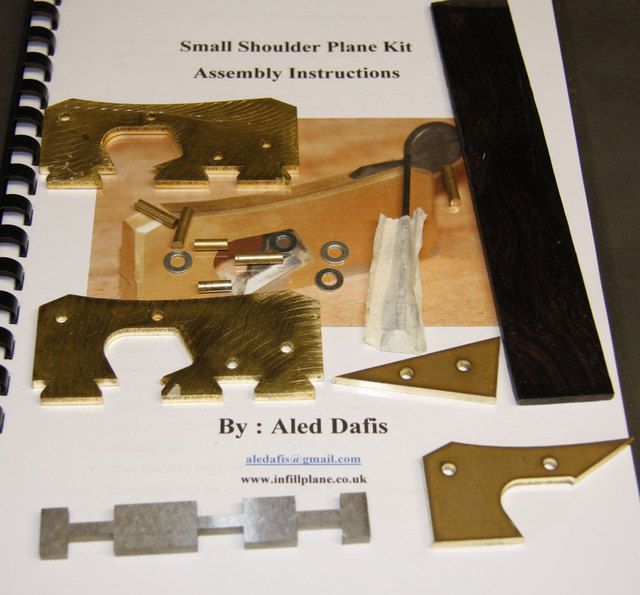

However in between stripping the paint from my garage door I managed to do a bit on Aled's Small Shoulder Plane Kit

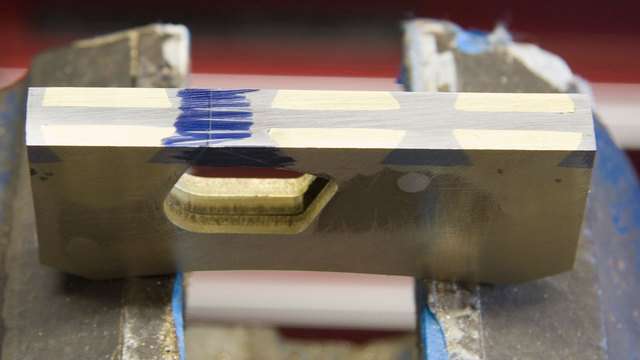

Dovetails cut and filed and temporary rivets fixed.

Now ready for peening!

(Some of the "shadows" are marker pen marks).

Rod

However in between stripping the paint from my garage door I managed to do a bit on Aled's Small Shoulder Plane Kit

Dovetails cut and filed and temporary rivets fixed.

Now ready for peening!

(Some of the "shadows" are marker pen marks).

Rod