Hi Aled

I certainly wouldn't be modest about your description...it makes perfect sense and is very understandable.

I made some cock-ups which I fully expected to do...the peining is and has always been a weak point of mine...getting the right size hammer...not hitting it too hard...being patient....knowing when to carry on and when to stop...but I will show later...

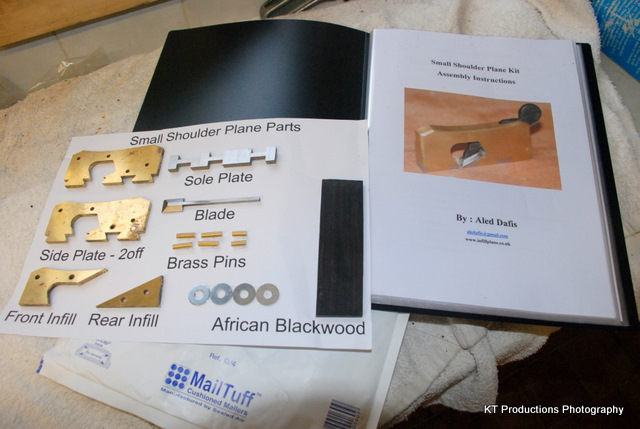

In the meantime some progress shots...the dovetails...

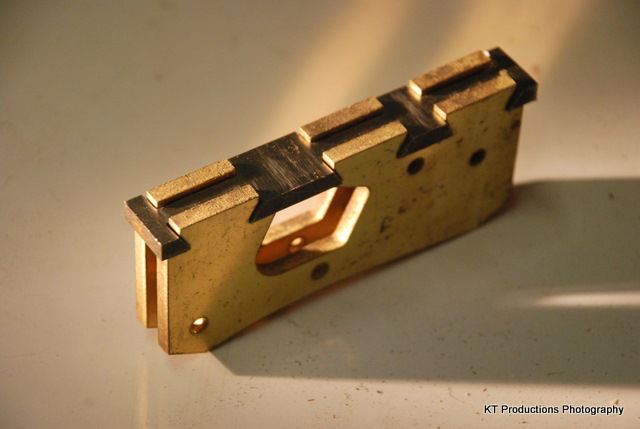

This I thought would be the difficult bit but it turned out to be the easiest bit....

I screwed up one side of one dovetail...near one end at the sawing stage....I thought it could be filled by peining but it was not so...I therefore have a tiny bit not filled in which we shall see at the finished...

But generally it came through this stage ok...

I didn't get any shots of the pin peining stage as I was too busy trying to get them right...but we shall see how good/bad they are later. I am not overly worried as I want this to be a working instrument so I was more worried about getting the iron at the right angle and the best mouth I could.

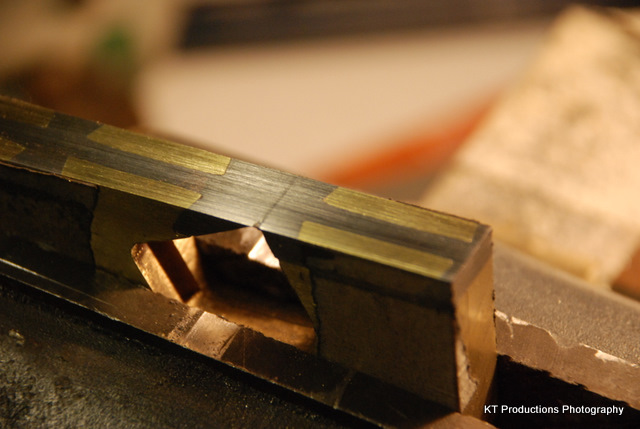

Getting it flat and square was something that Aled says is a "make or break" part...and it surely is...this bit made me think and take super care...but here is the breakthrough at the right angle and exactly where it should be....(this is almost atomic level breakthrough...there is no pencil line here...that is a ridge!)

See the void where I simply could not tease enough brass into the gap...it won't affect the operation but it is a PAIN! (no pun intended!)

There are also some tiny voids again were peining has not been aggressive enough at the corner of the dovetails...but what I wanted was the breakthrough to be correct and that worked a dream....

At this stage some more tips for those coming along...go buy a new bastard file....I tried to make do with my old one and it was knackered...just a few quid but BOY...did it help. Take the peining SLOWLY and patiently...not a major problem only from an esthetic point of view but none the less...it should be done slowly.

Back later with some more pictures....I have some work to do to get this baby square!

Jim