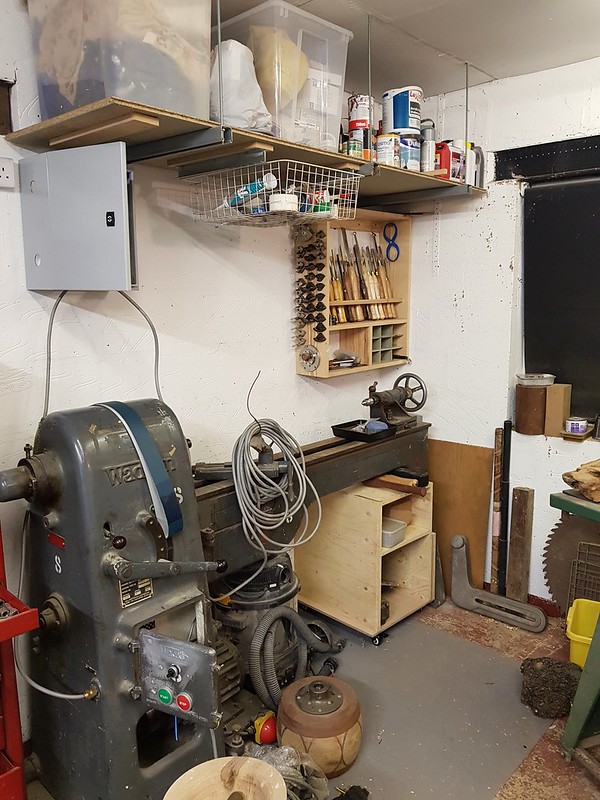

I've sold all the machines I didn't want now, and I've made my money back on the deal - and I've still got the wadkin lathe and the myford (given it to dad for his birthday!) Got the wadkin checked on my quick 3 phase testing rig at work and as expected it runs like a clock. Can't wait to start using it properly. I've made progress with the Harrison too - got the 240v motor out and am about ready to swap the 415v one back in. Once thats done I can move it back into it's final position.

In other tool acquisition news I've got the chance of clearing a local workshop full of industrial sized woodworking kit - if I get it out, clean it up and sell it on I get a cut of the profits - should work well. (or I'll just end up keeping the bits I want!) Can stick some pics up if anyone is interested when I get started on it?

Today I also picked up this:

From a terribly described facebook ad. From the pictures I thought it was a bench sized drill but when I got there and saw it I just rolled with it! Somewhat sweaty work deadlifting those chunks of iron into the van. Its a Grimston Electriska geared head drill. Not sure yet whether to keep it or sell when I've done it up - its possibly a bit excessive for my workshop (so is a wadkin RS though, right?), but its a lovely old machine. According to lathes.co.uk its a very early one with the gear levers on the right hand side of the head. So far it looks to be missing the rack the head winds up and down on but thats about it. All the pick-off gears are there, although one is missing a few teeth. Not bad for £80!

In other tool acquisition news I've got the chance of clearing a local workshop full of industrial sized woodworking kit - if I get it out, clean it up and sell it on I get a cut of the profits - should work well. (or I'll just end up keeping the bits I want!) Can stick some pics up if anyone is interested when I get started on it?

Today I also picked up this:

From a terribly described facebook ad. From the pictures I thought it was a bench sized drill but when I got there and saw it I just rolled with it! Somewhat sweaty work deadlifting those chunks of iron into the van. Its a Grimston Electriska geared head drill. Not sure yet whether to keep it or sell when I've done it up - its possibly a bit excessive for my workshop (so is a wadkin RS though, right?), but its a lovely old machine. According to lathes.co.uk its a very early one with the gear levers on the right hand side of the head. So far it looks to be missing the rack the head winds up and down on but thats about it. All the pick-off gears are there, although one is missing a few teeth. Not bad for £80!