It's pretty easy to see if a lathe's been abused - visible damage on the ways, any movement in the apron/carriage/slides. So long as thats all good and the main bearings sound and feel good, everything else can be fixed. Assume its chuffing heavy and if you dont have the kit to move it, pay someone who does and knows what they're doing. Unless you're an idiot like me who does this a lot then its a one time expense.Very jealous. I do like my little mini lathe (Chinese special, Sieg SC2 clone) but I'd love a "proper" old one like that. Quite a few come up for sale around where I live, but the unknowns of specs/sizes/weights/transport always makes me chicken out.

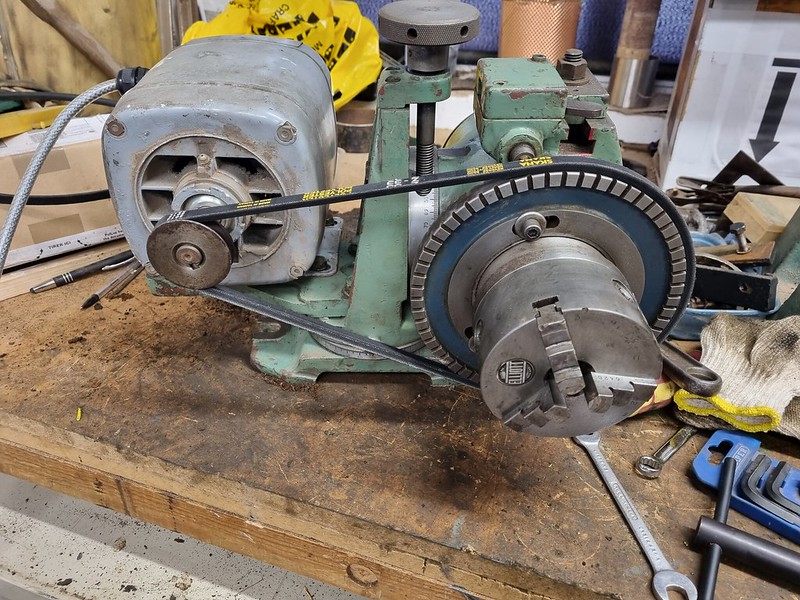

Got the last dovetail slide on the little deckel grinder moving last night - a few taps with a Thor No2 persuading stick and it gave up resisting. Tonight I pulled the work spindle apart and reassembled. The workholding part is all free and easy now, just need to get the old wheel off, rewire it and it should be good for a test.

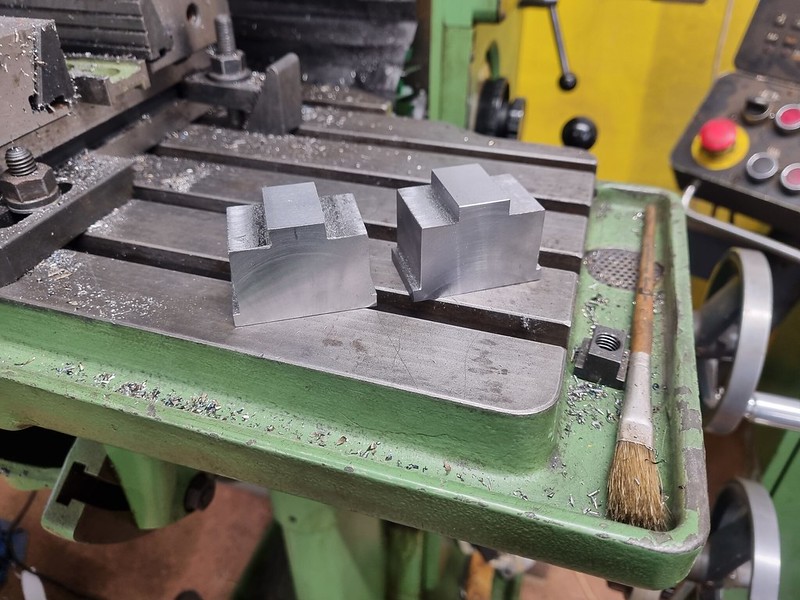

vice jaw inserts

vice jaw inserts Leinen Vice

Leinen Vice