wallace

Established Member

Lovely job. I'm chomping at the bit to do my big RU lathe

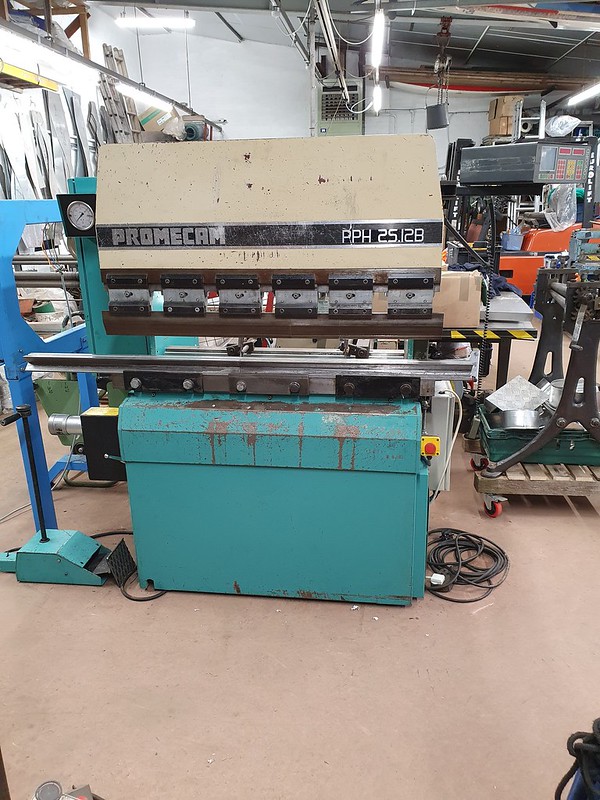

promecam

promecam plymovent

plymovent  Bandsaw before

Bandsaw before  Bandsaw finished

Bandsaw finishedTFrench":2gzc573g said:Can't wait to see that come together mate! What happened with the morticer they dropped?

Sent from my SM-G973F using Tapatalk

linisher

linisher linisher grinder

linisher grinder

5 C collet storage

5 C collet storage Die Filing Machine

Die Filing Machine TFrench":265vrgfv said:And another cool little machine has joined the restoration queue:

An excel no.2 Die filing machine. Most of the filing machines I've seen are benchtop sized. The guy had an even bigger one but they'd lost the table for it. Farmers.... (hammer) The rust isn't as bad as it looks - it moves freely so I'm hoping it will mainly be a clean up job...

adapter pin

adapter pin  original hole

original hole  finished job

finished jobIt can't half shift some wood! I need to make a couple of adapters so I can plug my extraction into it properly.Ooo, I've always wanted one of those disc/waterfall sander combos!