TrimTheKing

Established Member

Thanks Dave

I still don't get the rotation bit (brain just isn't working today), but I think from the other answers I have worked out what the issue is.

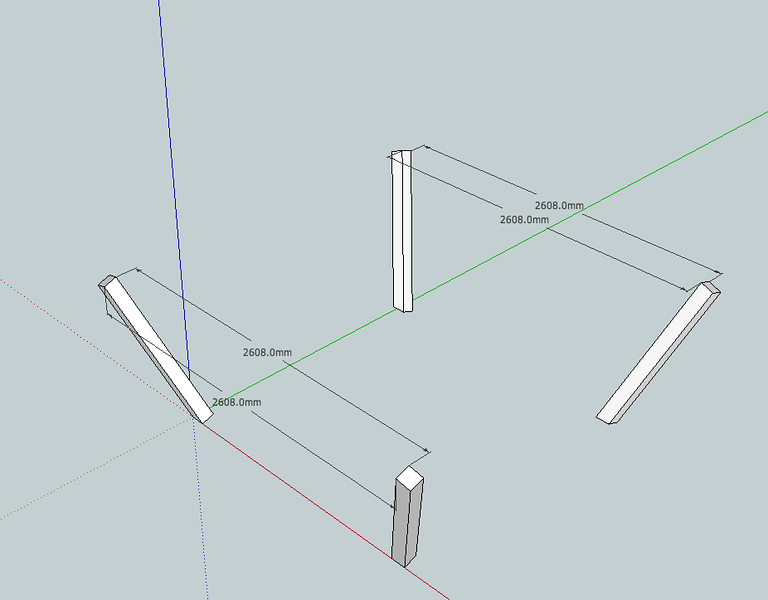

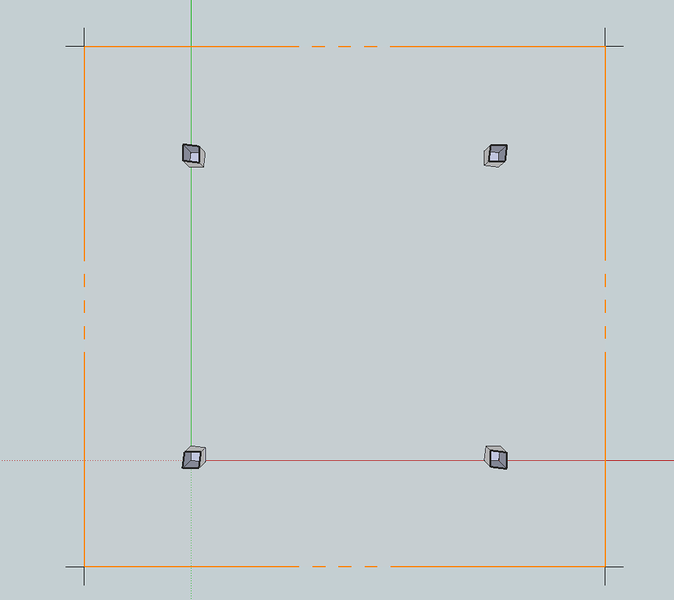

From these pics you can see that I have decided to keep the 5deg splay on the side rails too and compensate for the angle by angling the inner rail that the slats will rest on.

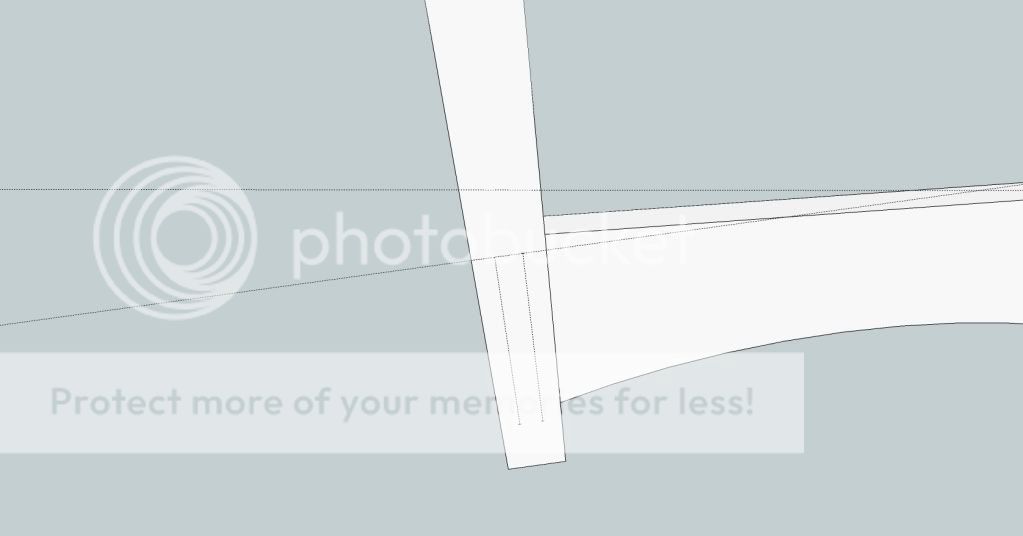

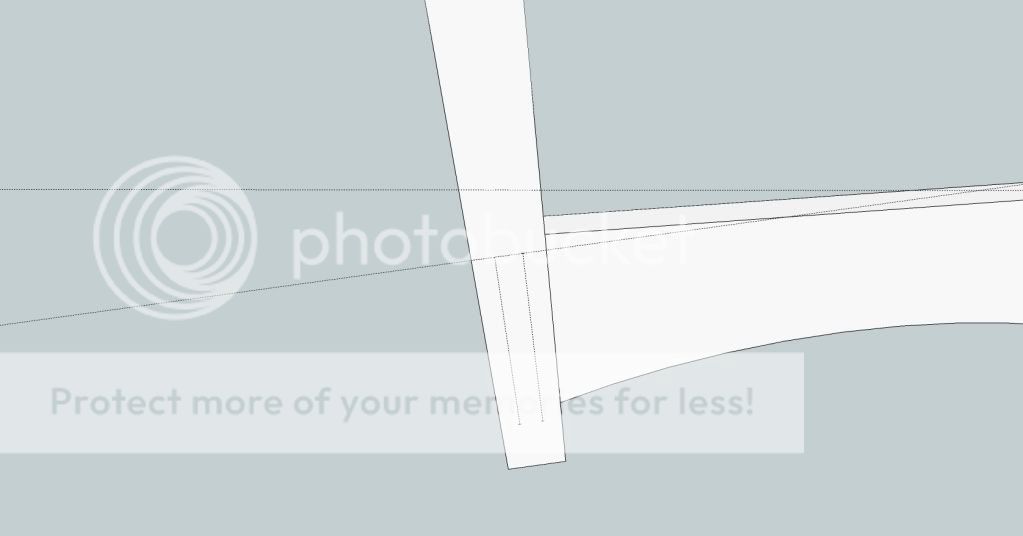

As per Chris' post, because I have marked up the guide points from the bottom edge of the leg (which is obviously at a 5 deg angle) the the inside faces of the rail are higher thus bringing in the small (0.22mm) gap you can see here.

In reality I don't think this tiny gap will make any difference at all to the build process but if anyone can offer a better way to do these side rails then I would be most happy.

Dave - As you say, when I build it I will build the head/foot boards flat and introduce the angle later, but I think I will still encounter this problem when I cant them backwards, or am I missing something (highly probable)...

I still don't get the rotation bit (brain just isn't working today), but I think from the other answers I have worked out what the issue is.

From these pics you can see that I have decided to keep the 5deg splay on the side rails too and compensate for the angle by angling the inner rail that the slats will rest on.

As per Chris' post, because I have marked up the guide points from the bottom edge of the leg (which is obviously at a 5 deg angle) the the inside faces of the rail are higher thus bringing in the small (0.22mm) gap you can see here.

In reality I don't think this tiny gap will make any difference at all to the build process but if anyone can offer a better way to do these side rails then I would be most happy.

Dave - As you say, when I build it I will build the head/foot boards flat and introduce the angle later, but I think I will still encounter this problem when I cant them backwards, or am I missing something (highly probable)...