I've got several nicely shaped chisels that just aren't that good (robert sorby, most notably, but also some older buck brothers).

It occurred to me that some of the things that work well on knives may also work well on chisels, but until recently I didn't pay enough attention to really figure it out. I can also reharden chisels (handles on and all), so it's really not that much of a priority.

But I decided I'd try the knife bevel thing (determining where an edge fails and eliminating only that, and not overstrenghthening anything else because it'll increase cut resistance - in chisels, this is cut and wedging resistance, though I suppose knives are the same).

what I've come up with is this:

* at 28 degrees flat bevel, my sorby chisels don't hold up well. Actually, no chisels that I have will really hold up well.

* I've come to figure out with experimentation that I can use a buffer to apply the final bevel to a very very tiny part of a chisel bevel and get far better penetration from the chisel, and edge holding that is monstrously better

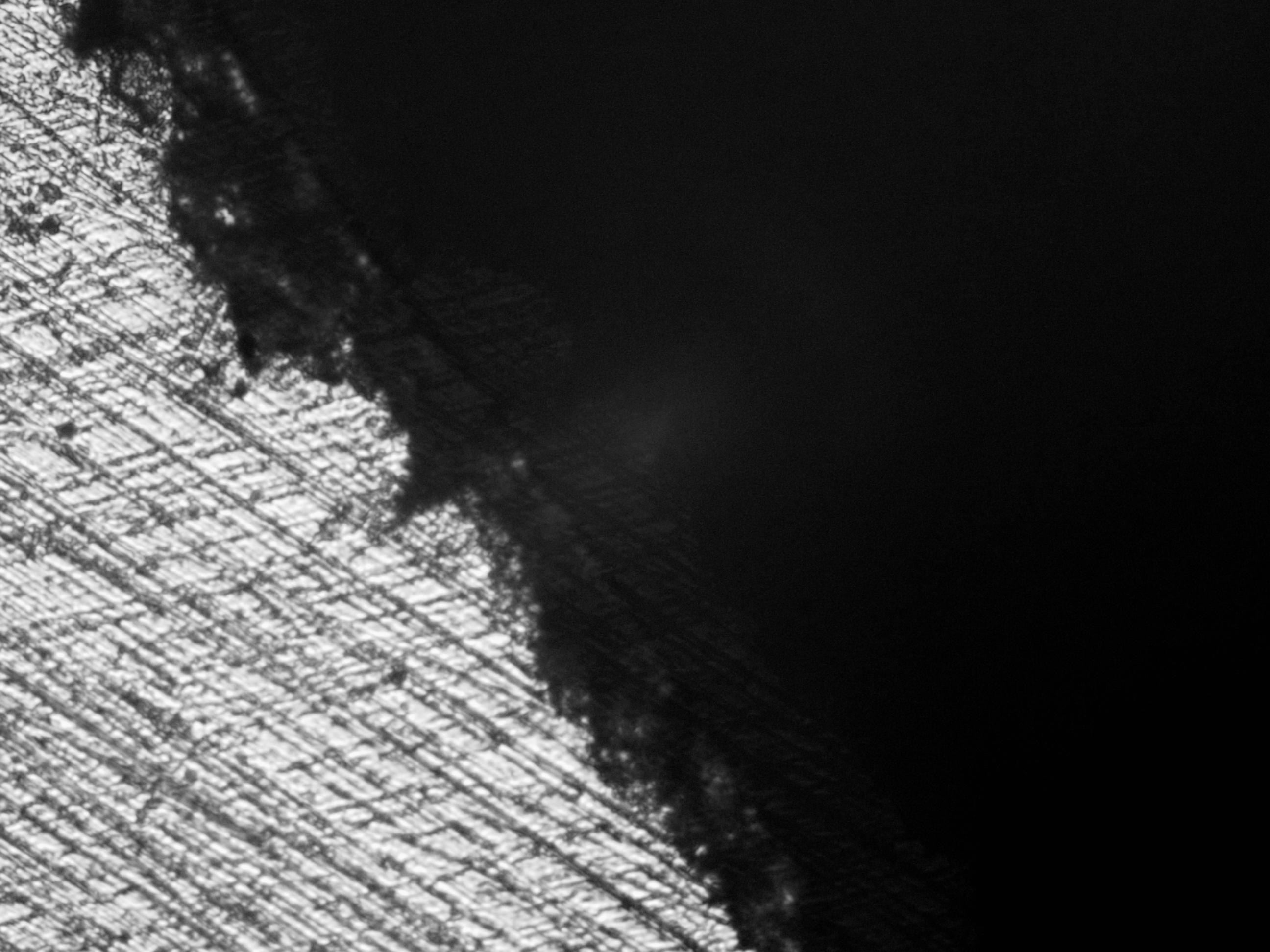

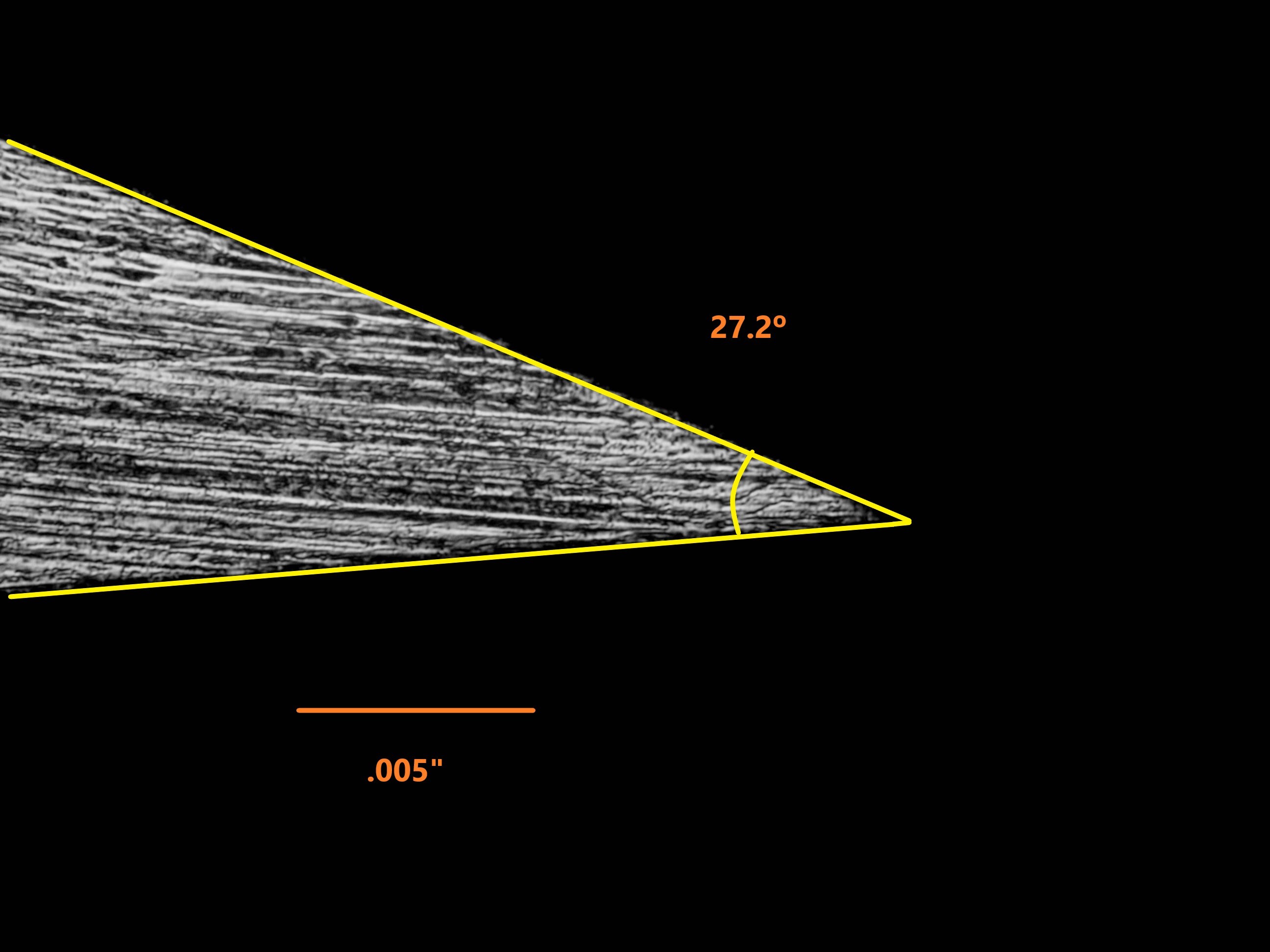

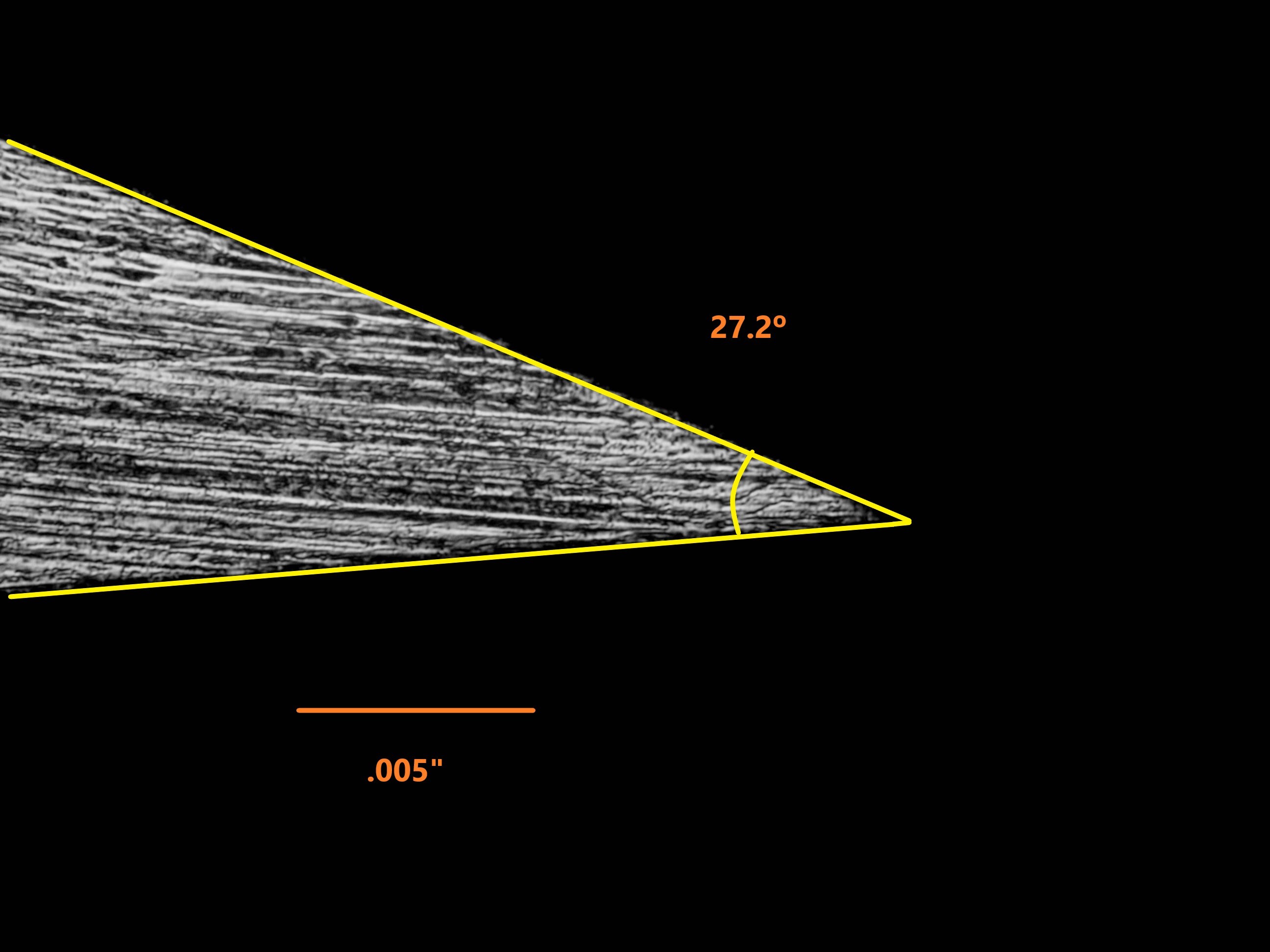

Pictures of this edge are as follows (targeting 28 degrees, came up around 27.2 - flat microbevel on a 20-couple primary).

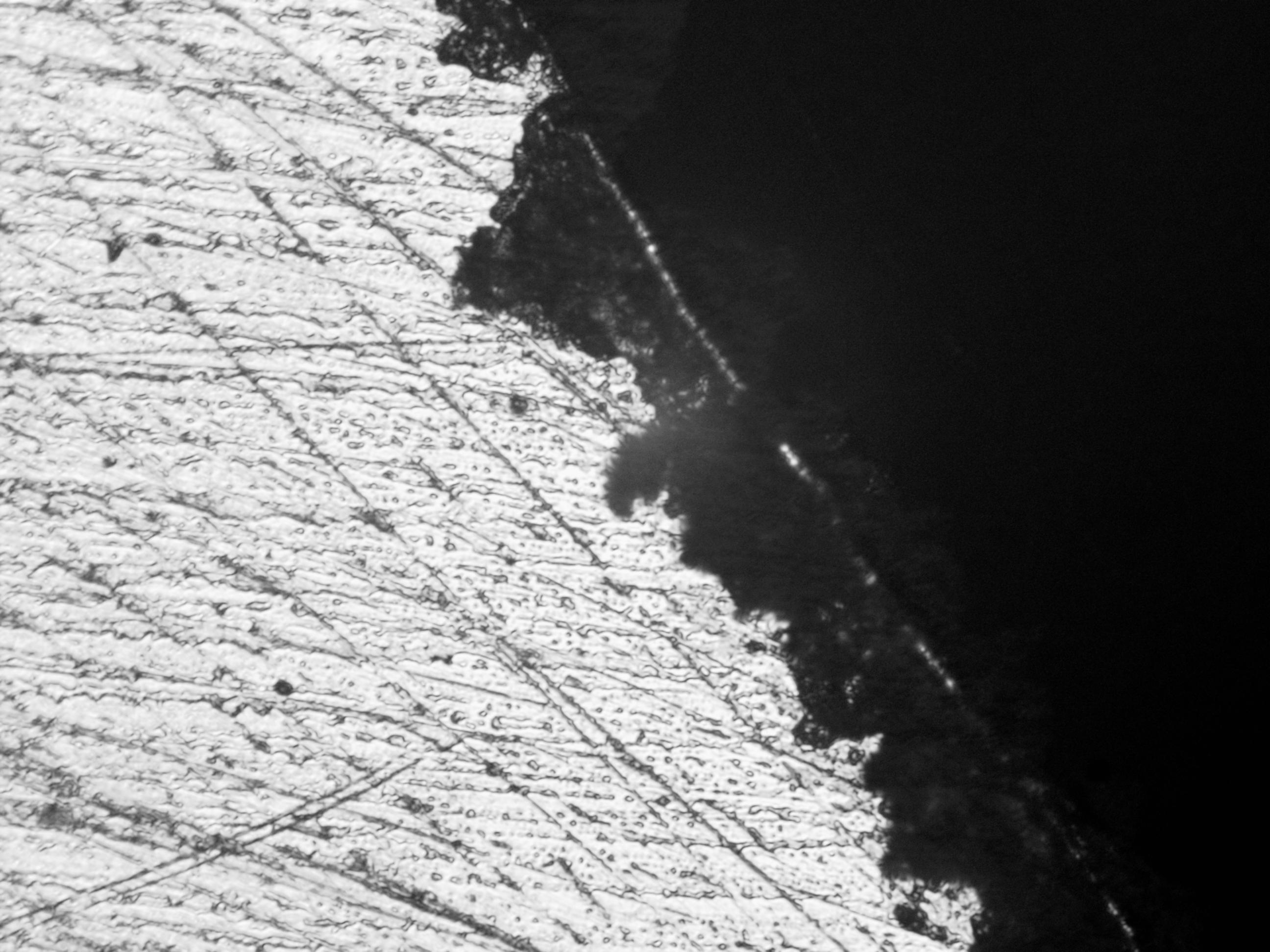

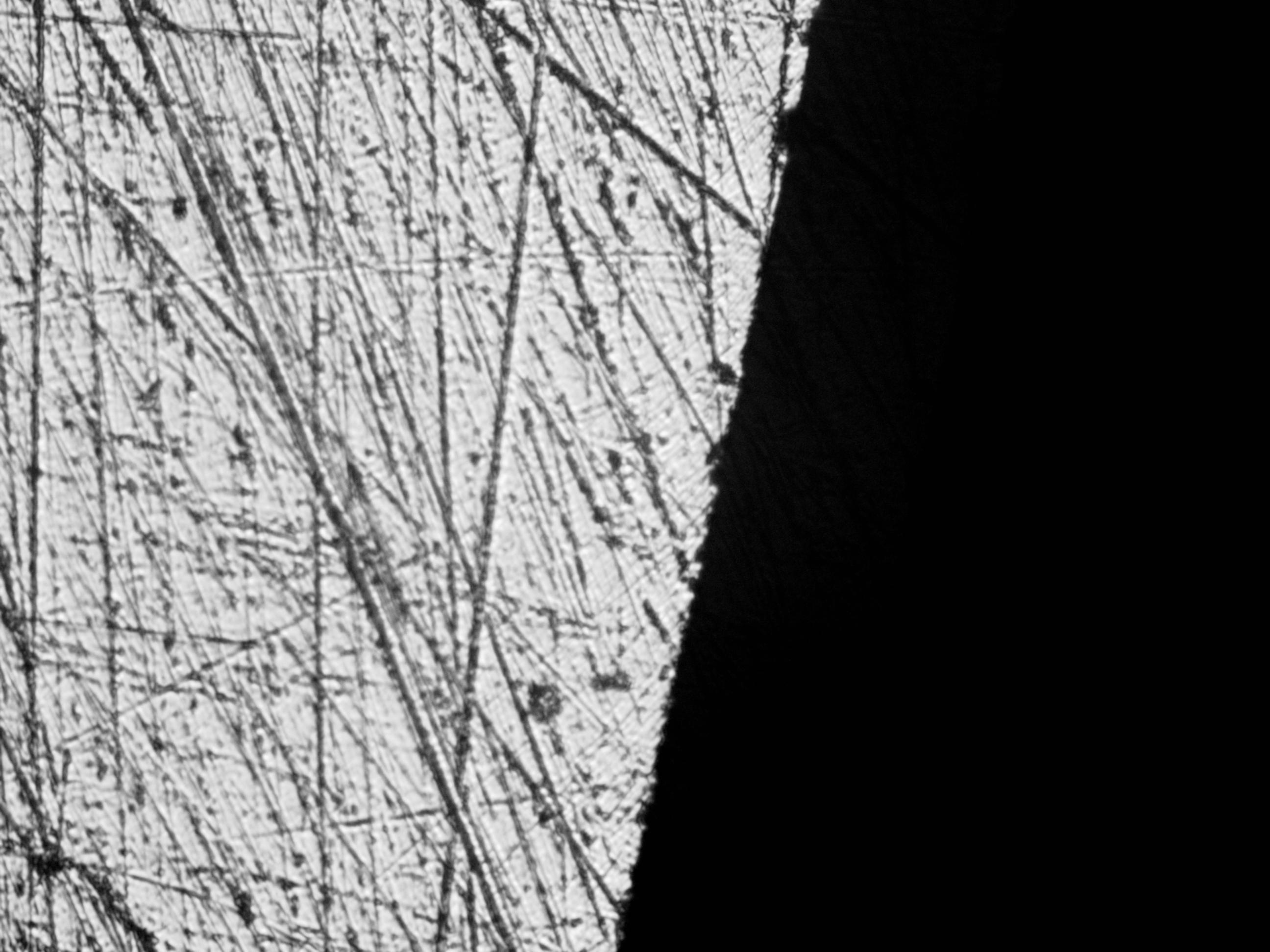

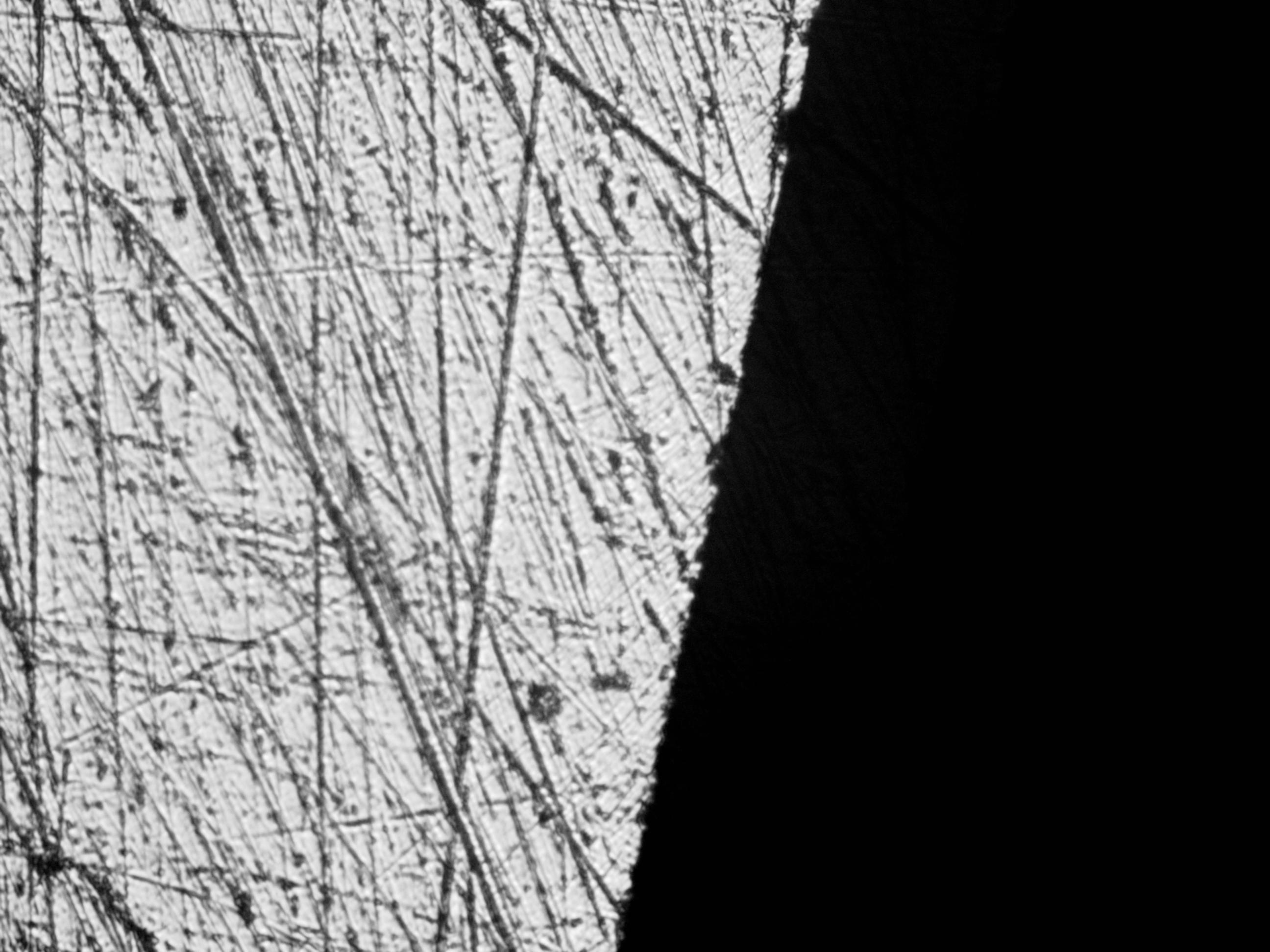

Here's what this chisel looked like after malleting two socket's worth (halfblinds, more or less) of smooth relatively easy working american beech:

These pictures are the same magnification - about two hundredths of an inch from top to bottom.

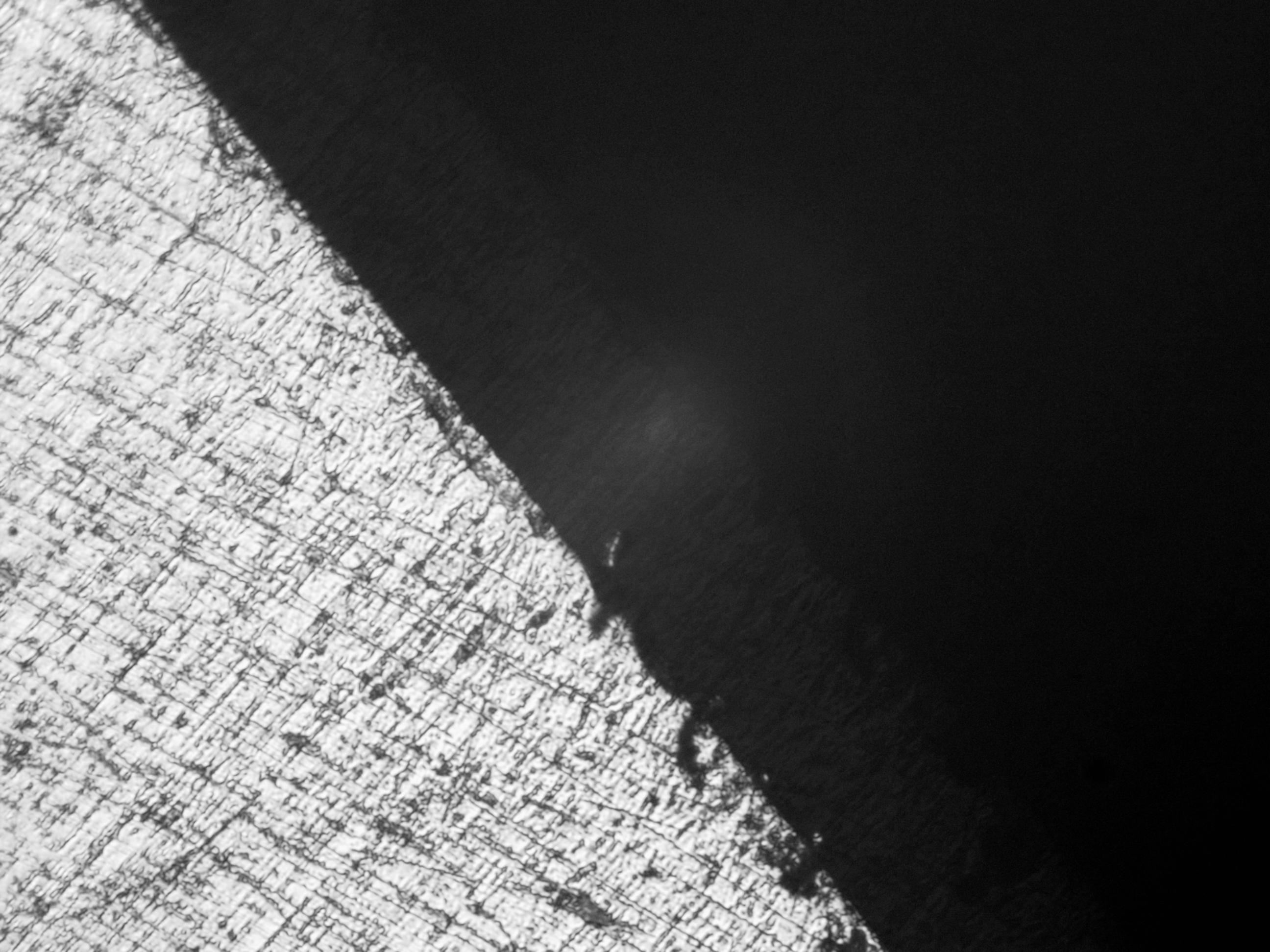

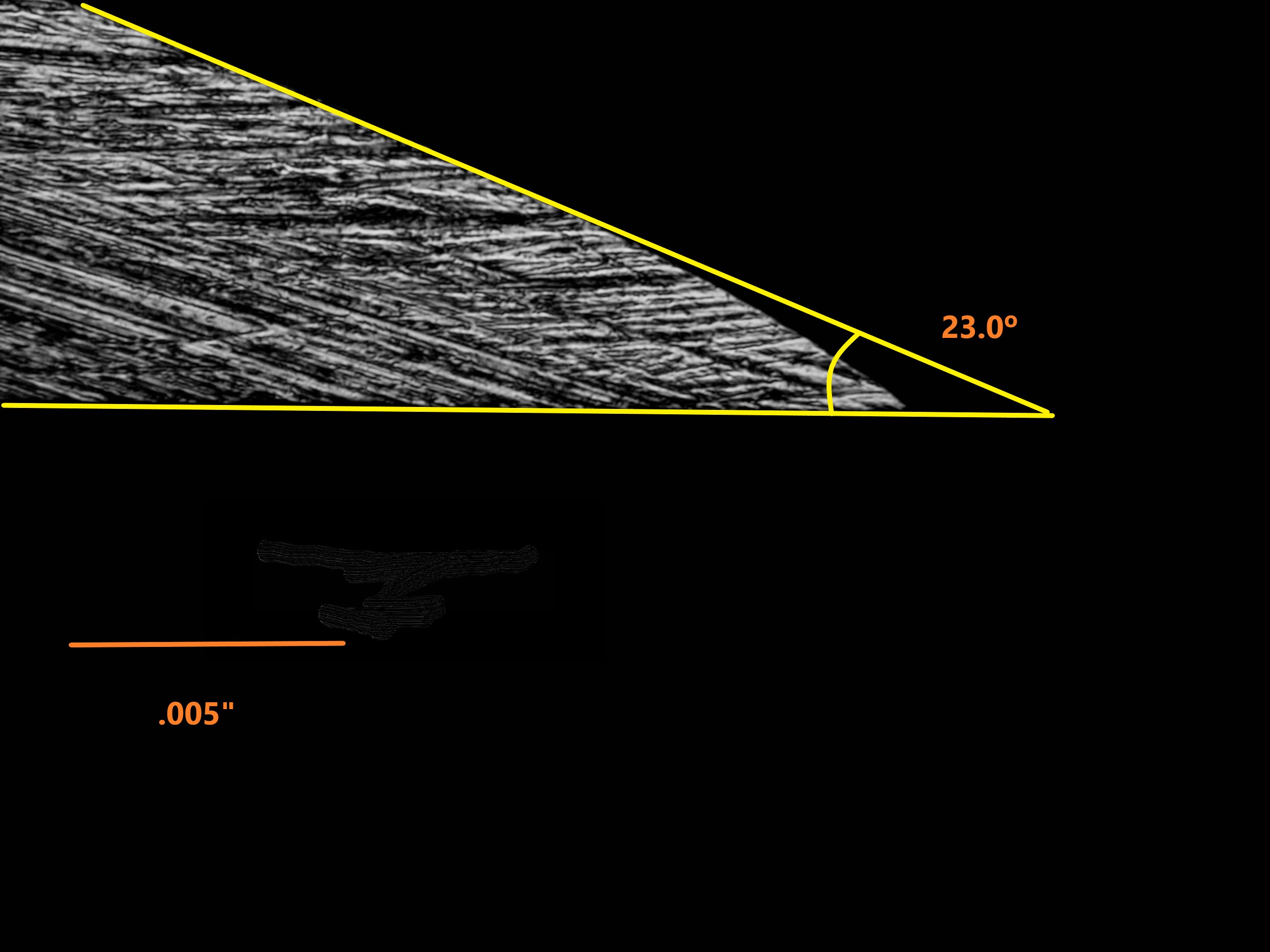

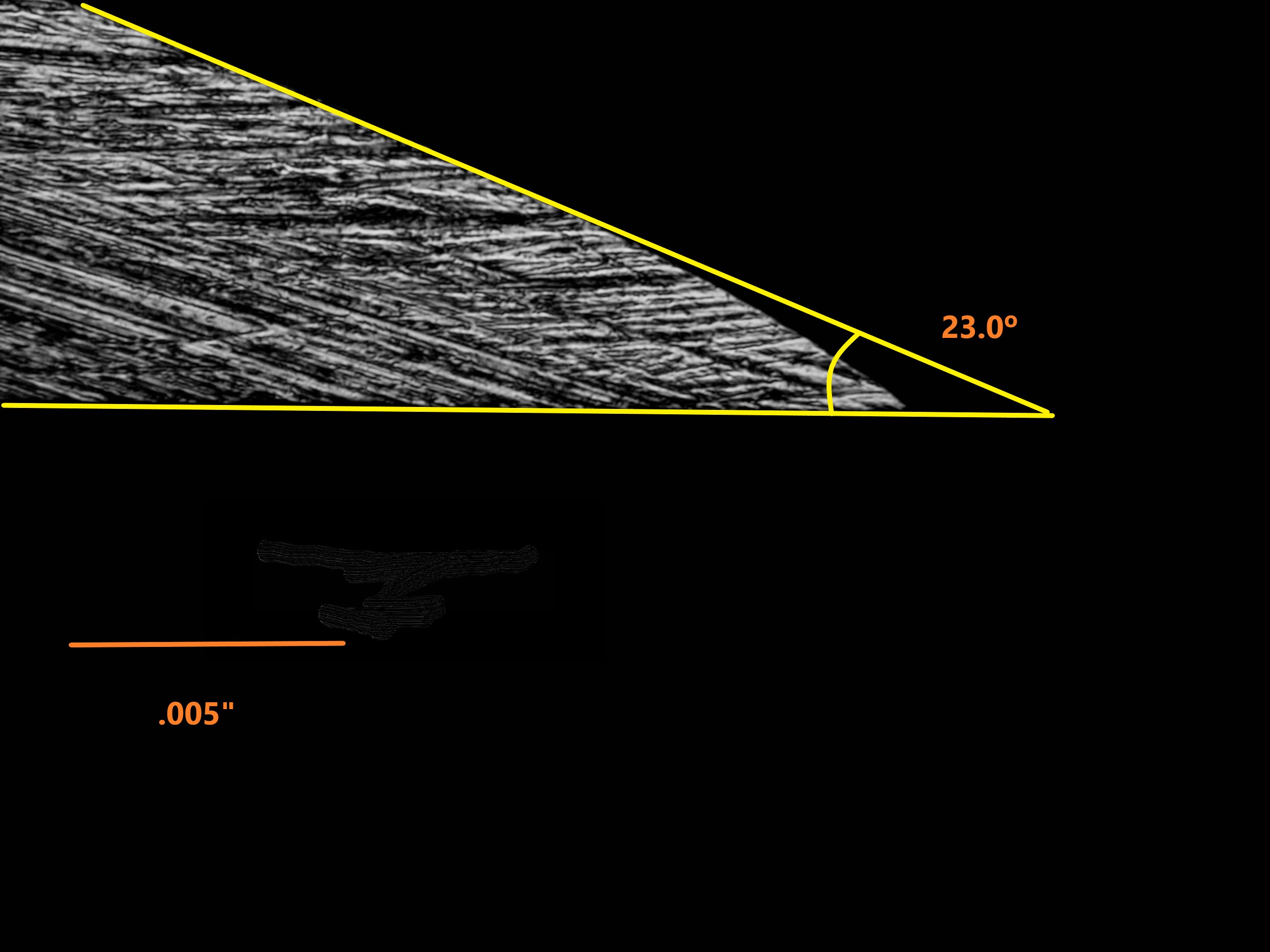

And here's the profile that solves this better than I expected - you are seeing the secondary bevel only at 23 degres, and the last 5-7 thousandths has been rounded over with a buffer just a little.

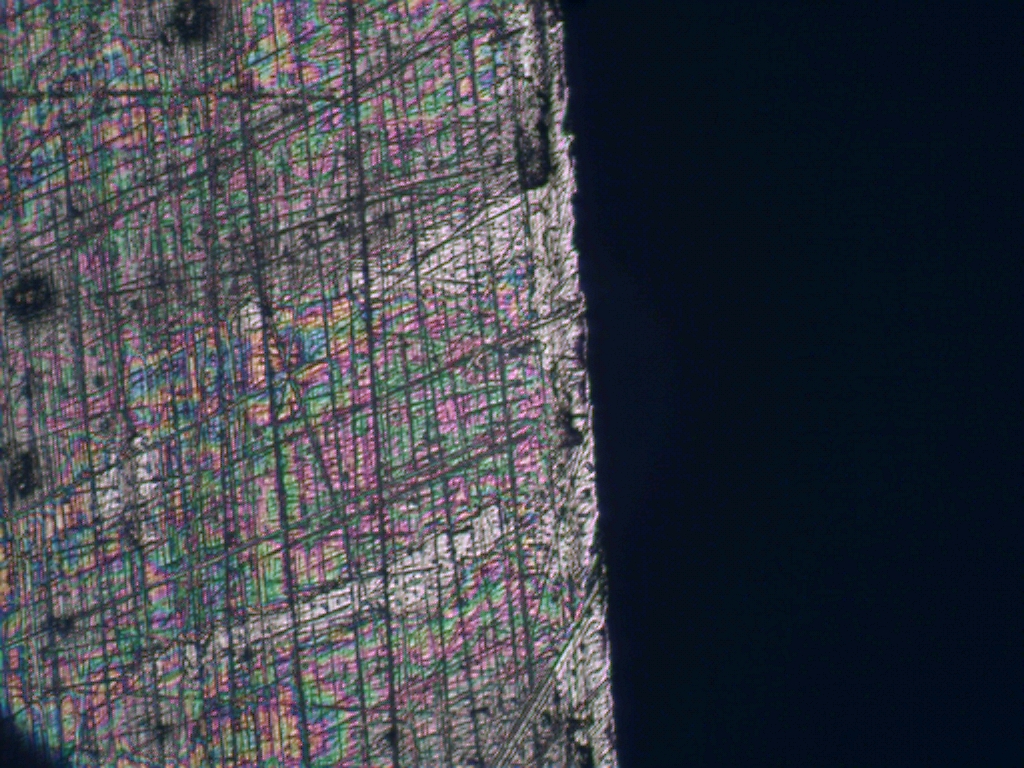

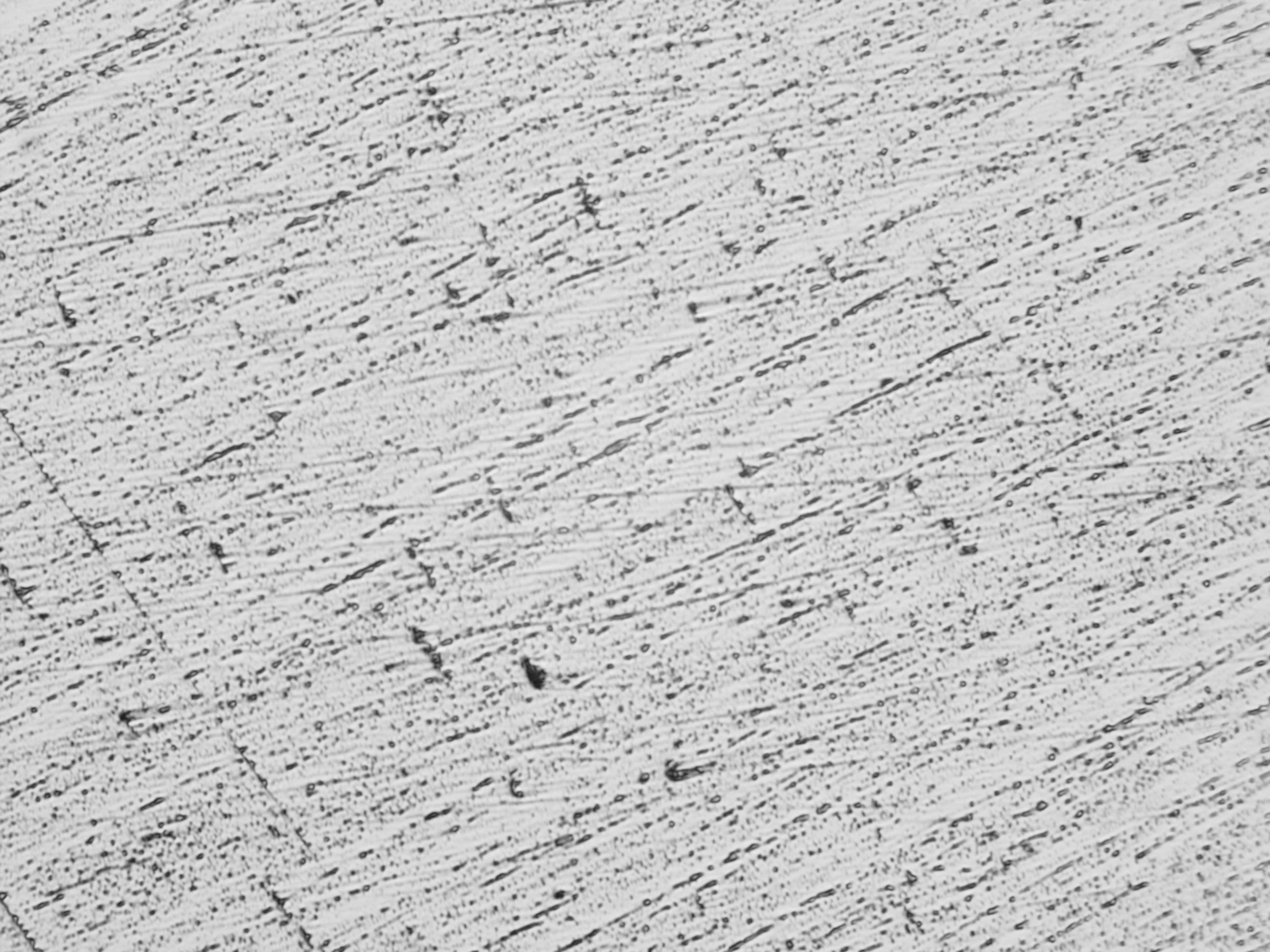

And here's what the back of the chisel looks like through the same wood (though at 1" wide, it actually took less in terms of mallet striking power to get this chisel through beech than it took the 28 degree chisel at 3/4ths wide). Fewer strikes and with less striking power.

I'd done a fairly poor job of preparing the back of this second chisel, but the reduction in edge damage is striking. Even if I'm not!!

I'm referring to this sharpening method as "the unicorn bevel", because we're often chasing unicorns in woodworking. In this case, it's finding a bevel that penetrates wood with less resistance, but holds up much better.

You can see where the damage usually occurs - it starts in the first couple of thousandths of the edge, and then as it gets deflected or chips, things go downhill from there. If we can prevent it from the start, things proceed far better.

The overall setup of this edge is something like follows

*20 degree primary

*23-25 degree secondary (just as any other microbevel method is applied, if the second bevel gets too long or steep, just regrind

* buff the very tip for about 5 seconds cotton buff then, 8 stitched, on a very cheap buffer (you have to experiment a little bit until both goals are met) for about 5 seconds with calcined alumina bar around 5 microns. none of these details are vitally important, but the finish level from the 5 micron stick on a cotton buff is about as good as 1 micron abrasive, maybe better (the buff doesn't have enough strength for the abrasive to really dig in).

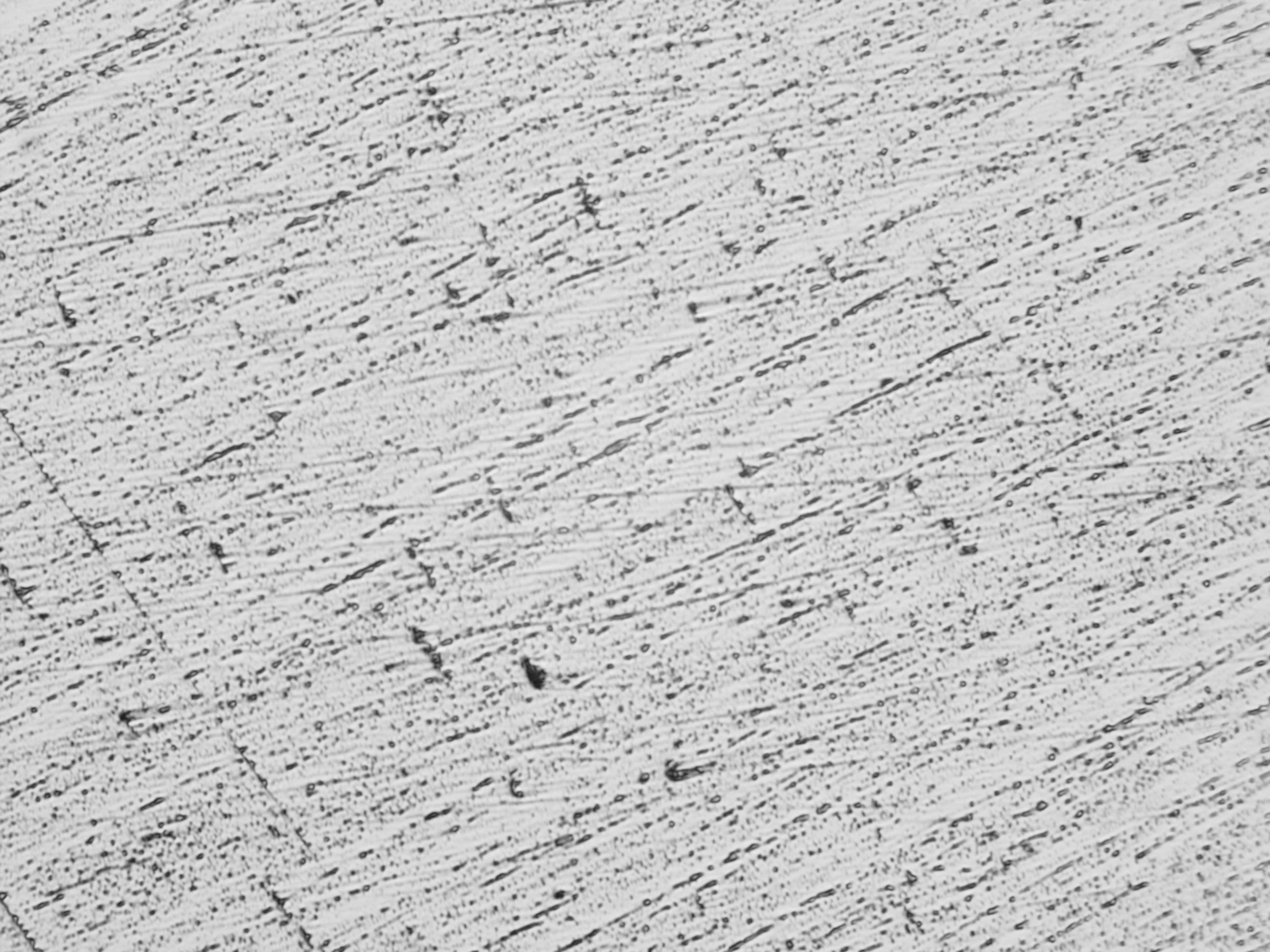

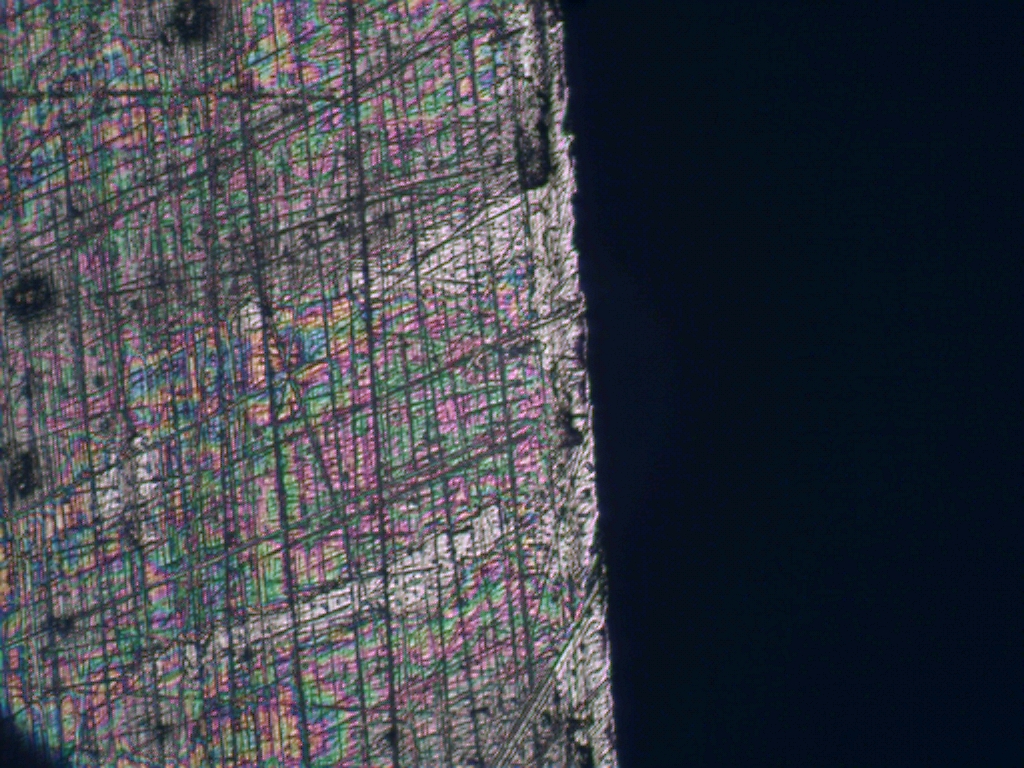

(that's the finish left by this fairly coarse buffing media - most of the lines are just light oil - it's really hard to wipe that off until it's gone at this magnification level).

For comparison, here is an edge from a black dan's arkansas stone with a polished honing surface.

The sharpening cycle time for this is about 30 seconds, even with some edge damage (you can still just abuse the chisel needlessly and damage the edge further up than the modifed area, but that's kind of dumb).

With this method, we have very simply done the following - removed or modified the very tip of the chisel where failure starts and propagates, and then taken advantage of the ability to narrow the edge behind it because that's not really where failure occurs, so why increase the amount of work done and wedge wood with it?

not just great for chopping, but also supreme for paring chisels. The cutting ability of this edge is as good as anything I've ever used sharpened any way I've ever sharpened. It's incredible. For those who keep a filthy shop as I do, nothing ever seems to stick in the buff and contaminate it, either.

It occurred to me that some of the things that work well on knives may also work well on chisels, but until recently I didn't pay enough attention to really figure it out. I can also reharden chisels (handles on and all), so it's really not that much of a priority.

But I decided I'd try the knife bevel thing (determining where an edge fails and eliminating only that, and not overstrenghthening anything else because it'll increase cut resistance - in chisels, this is cut and wedging resistance, though I suppose knives are the same).

what I've come up with is this:

* at 28 degrees flat bevel, my sorby chisels don't hold up well. Actually, no chisels that I have will really hold up well.

* I've come to figure out with experimentation that I can use a buffer to apply the final bevel to a very very tiny part of a chisel bevel and get far better penetration from the chisel, and edge holding that is monstrously better

Pictures of this edge are as follows (targeting 28 degrees, came up around 27.2 - flat microbevel on a 20-couple primary).

Here's what this chisel looked like after malleting two socket's worth (halfblinds, more or less) of smooth relatively easy working american beech:

These pictures are the same magnification - about two hundredths of an inch from top to bottom.

And here's the profile that solves this better than I expected - you are seeing the secondary bevel only at 23 degres, and the last 5-7 thousandths has been rounded over with a buffer just a little.

And here's what the back of the chisel looks like through the same wood (though at 1" wide, it actually took less in terms of mallet striking power to get this chisel through beech than it took the 28 degree chisel at 3/4ths wide). Fewer strikes and with less striking power.

I'd done a fairly poor job of preparing the back of this second chisel, but the reduction in edge damage is striking. Even if I'm not!!

I'm referring to this sharpening method as "the unicorn bevel", because we're often chasing unicorns in woodworking. In this case, it's finding a bevel that penetrates wood with less resistance, but holds up much better.

You can see where the damage usually occurs - it starts in the first couple of thousandths of the edge, and then as it gets deflected or chips, things go downhill from there. If we can prevent it from the start, things proceed far better.

The overall setup of this edge is something like follows

*20 degree primary

*23-25 degree secondary (just as any other microbevel method is applied, if the second bevel gets too long or steep, just regrind

* buff the very tip for about 5 seconds cotton buff then, 8 stitched, on a very cheap buffer (you have to experiment a little bit until both goals are met) for about 5 seconds with calcined alumina bar around 5 microns. none of these details are vitally important, but the finish level from the 5 micron stick on a cotton buff is about as good as 1 micron abrasive, maybe better (the buff doesn't have enough strength for the abrasive to really dig in).

(that's the finish left by this fairly coarse buffing media - most of the lines are just light oil - it's really hard to wipe that off until it's gone at this magnification level).

For comparison, here is an edge from a black dan's arkansas stone with a polished honing surface.

The sharpening cycle time for this is about 30 seconds, even with some edge damage (you can still just abuse the chisel needlessly and damage the edge further up than the modifed area, but that's kind of dumb).

With this method, we have very simply done the following - removed or modified the very tip of the chisel where failure starts and propagates, and then taken advantage of the ability to narrow the edge behind it because that's not really where failure occurs, so why increase the amount of work done and wedge wood with it?

not just great for chopping, but also supreme for paring chisels. The cutting ability of this edge is as good as anything I've ever used sharpened any way I've ever sharpened. It's incredible. For those who keep a filthy shop as I do, nothing ever seems to stick in the buff and contaminate it, either.