my mistake, looking again at the 1963 catalogue it is only the standard QR vice that has the cover. The 'D' model (the one with the dog in the front jaw) does not. I have never really looked into what happened to the design after the merger with Ridgeway and subsequent acquisition by Irwin but I suspect the cover was probably dropped in the late 70s/early 80s. Can you even get a modern copy with the screw and nut cover?

A bodgers workbench

- Thread starter user 29368

- Start date

Help Support UKworkshop.co.uk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

user 29368

Established Member

- Joined

- 12 Sep 2018

- Messages

- 79

- Reaction score

- 172

All done. Left it clamped up over night, it's as flat and level as I could have hoped for, the cauls did a good job. Will begin planing and sanding once it stops raining.

Thank you for the advice with this so far.

Thank you for the advice with this so far.

Attachments

user 29368

Established Member

- Joined

- 12 Sep 2018

- Messages

- 79

- Reaction score

- 172

It's been a while...

The project got delayed, however it's now finished and functioning as a work bench.

The vice isn't close enough to the edge, but other than that I'm happy with it. Way more solid than I'll need for what is light DIY work. Thank you for all the help a couple of months ago.

here are a few pictures.

![20180928_163222_resized[6514].jpg 20180928_163222_resized[6514].jpg](https://cdn.imagearchive.com/ukworkshop/data/attach/57/57437-20180928-163222-resized-6514-.jpg)

![20181007_132912_resized[6512].jpg 20181007_132912_resized[6512].jpg](https://cdn.imagearchive.com/ukworkshop/data/attach/57/57439-20181007-132912-resized-6512-.jpg)

Decided to fit a plywood top, (18mm) can be easily swapped when it gets worn out, secured in place with 4 t nuts and bolts.

The project got delayed, however it's now finished and functioning as a work bench.

The vice isn't close enough to the edge, but other than that I'm happy with it. Way more solid than I'll need for what is light DIY work. Thank you for all the help a couple of months ago.

here are a few pictures.

![20180928_163222_resized[6514].jpg 20180928_163222_resized[6514].jpg](https://cdn.imagearchive.com/ukworkshop/data/attach/57/57437-20180928-163222-resized-6514-.jpg)

![20181007_132912_resized[6512].jpg 20181007_132912_resized[6512].jpg](https://cdn.imagearchive.com/ukworkshop/data/attach/57/57439-20181007-132912-resized-6512-.jpg)

Decided to fit a plywood top, (18mm) can be easily swapped when it gets worn out, secured in place with 4 t nuts and bolts.

Attachments

Stanleymonkey

Established Member

Very nice!

Those pictures look like they have come straight from the pages of a diy magazine!

Those pictures look like they have come straight from the pages of a diy magazine!

Mike Jordan

Established Member

As stated you will need clamps at some stage so it's not money wasted, if all else fails think like a woodworker! Mortise and tenon joints are easy to draw bore together, no clamps or straps required.

bourbon

Established Member

very nice looking bench there. You must really must put some crap on it so It looks like my bench!

£17.99 (£1.80 / count)

£27.44 (£2.74 / count)

3M 8822 Disposable-fine dust mask FFP2 (10-pack)

Amazon.co.uk

£17.99 (£9.00 / count)

JORGENSEN 300mm Professional Woodworking Clamps 2 Pack, Quick Release Clamps for Wood, F Clamps Set

GreatStarTools

£12.50 (£1.25 / count)

£14.45 (£1.44 / count)

JSP M632 FFP3moulded Disposable Dustmask (Box of 10) One Size suitable for Construction, DIY, Industrial, Sanding, dust protection 99 Percent particle filtration Conforms and Complies to EN 149

Amazon.co.uk

£96.66

£102.61

O'SKOOL Mortise and Tenon Jig is Ideal for cabinets, Chairs, and Table Construction Using a Plunge Router

Amazon US

£13.99 (£2.80 / count)

VEVOX® FFP1 Dust Mask - Set of 5 - Valved Face Masks - Respirator - Protection e.g. for Construction, Building Work, Sanding, Woodworking, Fine Dusts, Aersoles or Particles

SLSK Ventures GmbH (UK)

Jacob

What goes around comes around.

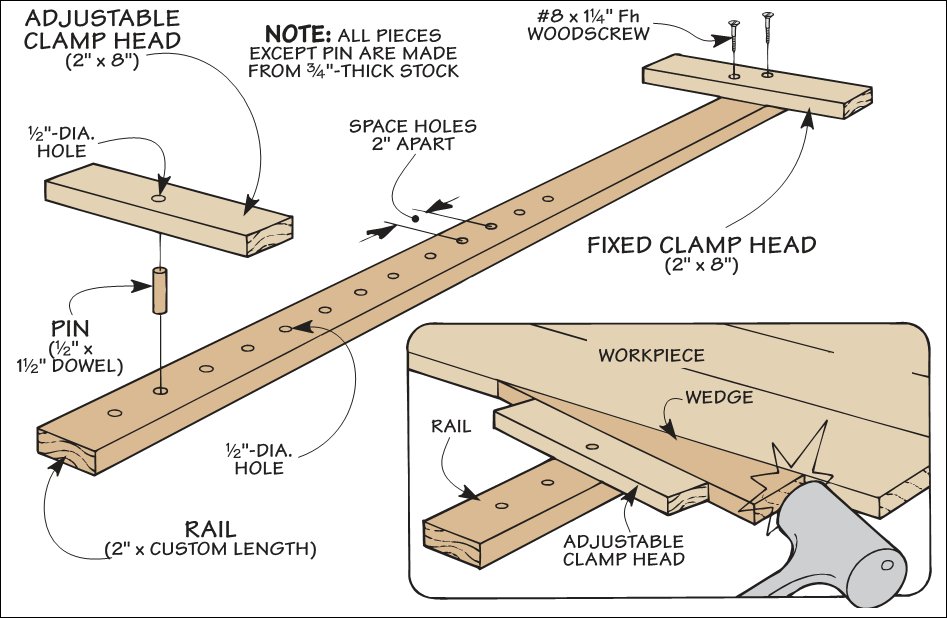

Could do Fitzroy's thing here but double it up so there's a top and bottom hole board with the pin going through both (bits of broom handle). Keeps it all straighter and allows more cramping pressure. Probably easier to glue just 2 or 3 at a time and you stay more in control. Cover the glue lines or the clamp with parcel tape or something so you don't glue the clamp or wedges to the workpiece. Use plenty of glue spread ALL OVER BOTH meeting faces.Fitzroy":2s5y0moy said:.......

....

Similar threads

- Replies

- 16

- Views

- 3K

- Replies

- 14

- Views

- 2K

- Replies

- 6

- Views

- 2K

- Replies

- 113

- Views

- 18K

![20180928_163222_resized[6514].jpg](https://cdn.imagearchive.com/ukworkshop/data/attachments/57/57437-d01ce758c4da5ff75f368a5afbfa80b6.jpg)

![20181007_132912_resized[6512].jpg](https://cdn.imagearchive.com/ukworkshop/data/attachments/57/57439-a109b6f4a6a72c97c21e319ca3df7572.jpg)