Rhyolith

Established Member

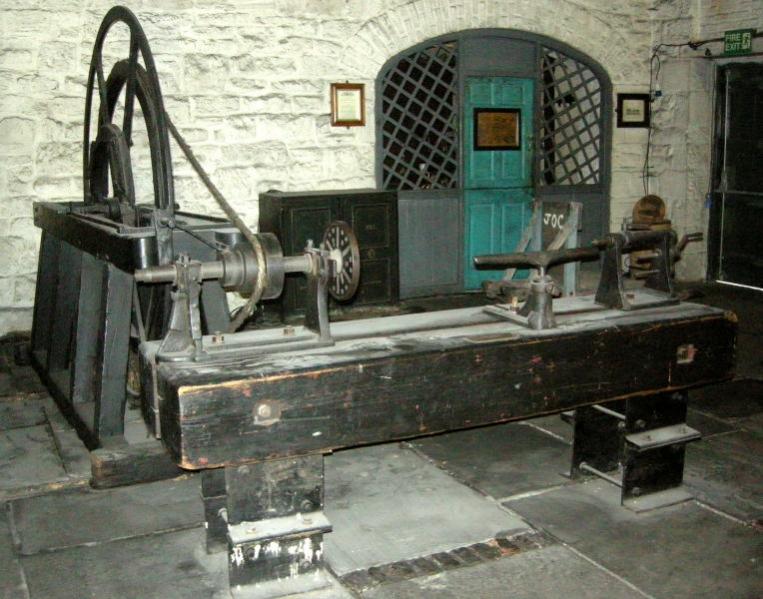

I have here what I think is a 19th Century wood Lathe from a water mill.

Llanio Mill Lathe by Rhyolith, on Flickr

Llanio Mill Lathe by Rhyolith, on Flickr

I think I know which mill it came from too thanks to a stamp on the tail stock:

Llanio Mill Lathe by Rhyolith, on Flickr

Llanio Mill Lathe by Rhyolith, on Flickr

This one: http://www.coflein.gov.uk/en/site/24765 ... ntium-mill

That is not that far from where I bought the lathe so I think that being its origin is quite plausible. The seller didn't know much about its origin. I never got round to going to look at this mill while I was in Wales so at the moment thats all I know.

Any further insights?

-----

I want to get it running and I have a few queries.

I believe this type of lathe would have had a wooden bed, which I don't have. It seems to fit well on some 3x6" i have, though these pieces are not long enough. Should I be using pine or hardwood? Where's the best place to source some decent quality bits?

I plane to mount it on two narrow A-frames, though i think most of these original were on two single 'pillars' rather than a frame. Like this: http://www.practicalmachinist.com/vb/at ... 030355.jpg

Any thoughts?

My biggest concern though is the set up to power this thing. It obviously runs on belts, from the ceiling originally I imagine, but i am not sure what I am doing here.

First problem is the belt set up. It cannot have the belts fed up from underneath as the base of the head stock is wider than the pulley (even the largest one), so it has to come from either above or to the side.

Second is the motor. Where do I get one and what am i looking for? I don't have 3 phase.

A scaler image (the ruler on top of the head stock pulley is a 30cm):

Llanio Mill Lathe by Rhyolith, on Flickr

Llanio Mill Lathe by Rhyolith, on Flickr

This is a long term project, at the moment I mainly want to know how much money I need to get this working and how long it would take.

As an aside: I feel kinda bad taking this piece of Welsh history so far from Wales, so once I am done with it I will return it to Ceredigion.

Llanio Mill Lathe by Rhyolith, on Flickr

Llanio Mill Lathe by Rhyolith, on FlickrI think I know which mill it came from too thanks to a stamp on the tail stock:

Llanio Mill Lathe by Rhyolith, on Flickr

Llanio Mill Lathe by Rhyolith, on FlickrThis one: http://www.coflein.gov.uk/en/site/24765 ... ntium-mill

That is not that far from where I bought the lathe so I think that being its origin is quite plausible. The seller didn't know much about its origin. I never got round to going to look at this mill while I was in Wales so at the moment thats all I know.

Any further insights?

-----

I want to get it running and I have a few queries.

I believe this type of lathe would have had a wooden bed, which I don't have. It seems to fit well on some 3x6" i have, though these pieces are not long enough. Should I be using pine or hardwood? Where's the best place to source some decent quality bits?

I plane to mount it on two narrow A-frames, though i think most of these original were on two single 'pillars' rather than a frame. Like this: http://www.practicalmachinist.com/vb/at ... 030355.jpg

Any thoughts?

My biggest concern though is the set up to power this thing. It obviously runs on belts, from the ceiling originally I imagine, but i am not sure what I am doing here.

First problem is the belt set up. It cannot have the belts fed up from underneath as the base of the head stock is wider than the pulley (even the largest one), so it has to come from either above or to the side.

Second is the motor. Where do I get one and what am i looking for? I don't have 3 phase.

A scaler image (the ruler on top of the head stock pulley is a 30cm):

Llanio Mill Lathe by Rhyolith, on Flickr

Llanio Mill Lathe by Rhyolith, on FlickrThis is a long term project, at the moment I mainly want to know how much money I need to get this working and how long it would take.

As an aside: I feel kinda bad taking this piece of Welsh history so far from Wales, so once I am done with it I will return it to Ceredigion.