guineafowl21

Established Member

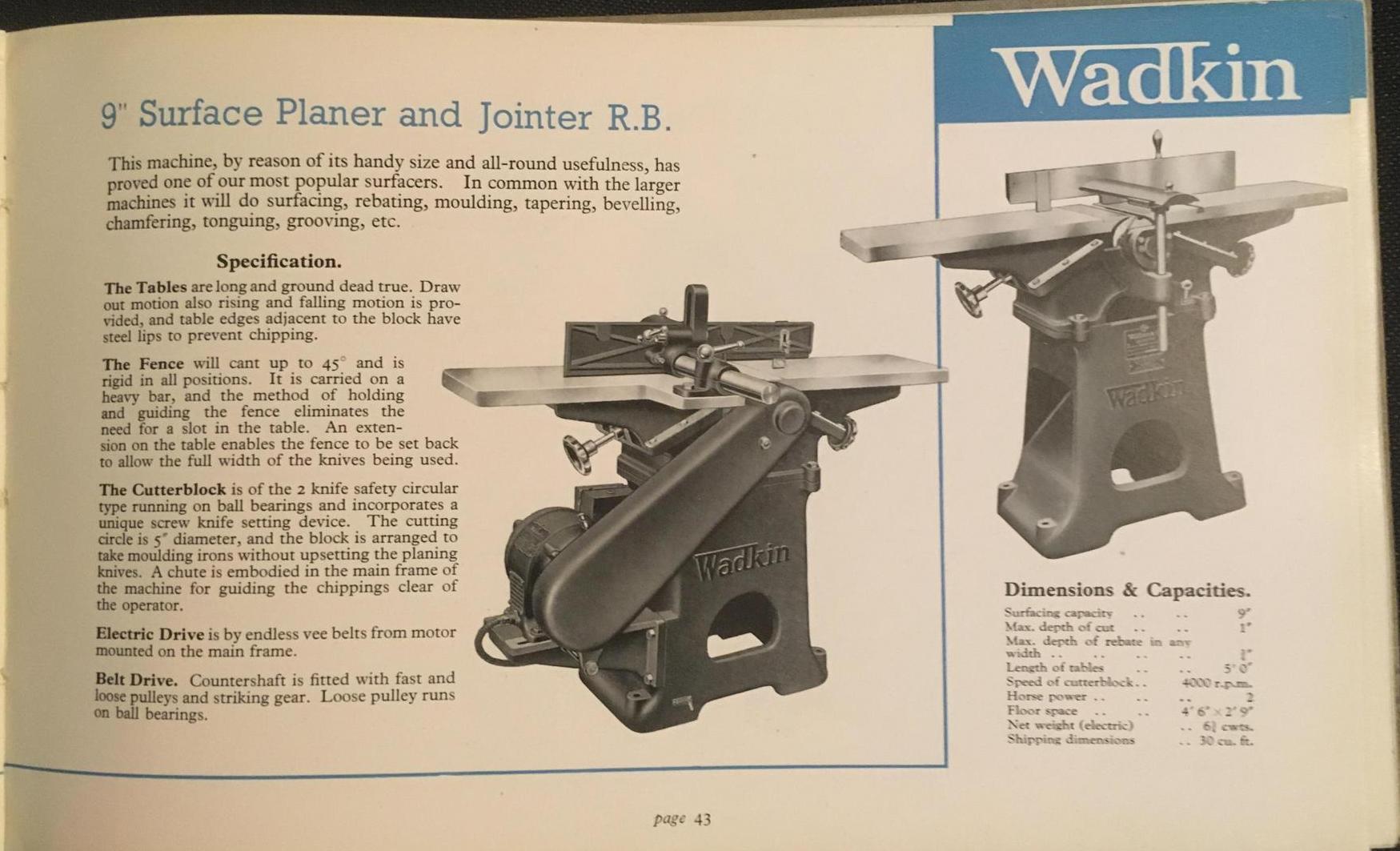

Does anyone know details of the motor fitted to these? I’m looking at one for sale, which appears to be unmodified, and three phase. I have three phase, but it would be a lot cheaper to run it from a VFD.

I’ve messaged the seller about the motor rating plate, but as with 50% of these cases they haven’t replied.

Is the motor dual voltage, or otherwise convertible? What hp?

I’ve messaged the seller about the motor rating plate, but as with 50% of these cases they haven’t replied.

Is the motor dual voltage, or otherwise convertible? What hp?