Mark A

Established Member

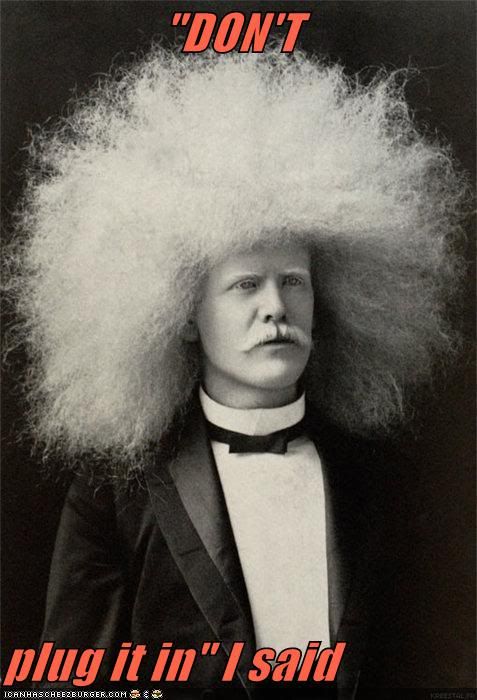

When using my belt sander connected to an old vacuum cleaner via a DIY "dust deputy" (traffic cone, 15l paint tin and a load of duct tape) I get static shocks when I touch the hose - one shock made my entire arm numb for about an hour. If I don't discharge the static on myself for a while I can actually see the sparks when I look down the hose and can hear it crackle a bit. Any thoughts on how I can prevent this??

Thanks

Thanks