condeesteso

Established Member

I may be getting a reputation for being a bandsaw nut, and it may be deserved.

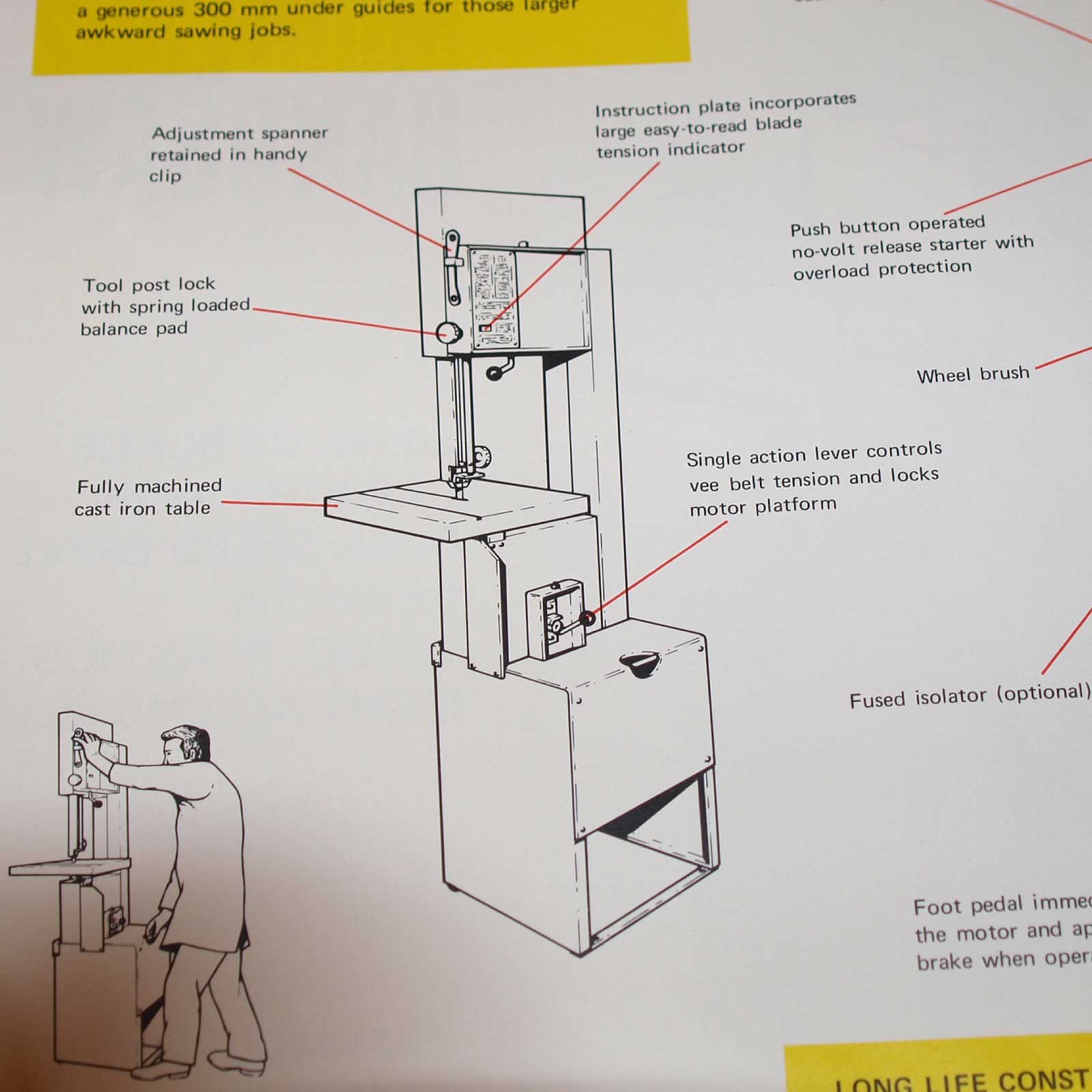

I recently acquired a 352, and before I got it did some online research (though I probably missed some info) - couldn't find much in the way of an overall summary and 'review', so for the possible benefit of anyone thinking about getting one, I shall do one here. Maybe some questions for fellow-owners also.

Here's one - what does this do? It is not set as the bolt from top should presumably work on the cam below.

So, this one is serial 111314 (no date on plate). I plan a trip to A.L.T. Saws in Gillingham for a few little bits for it, the odd knob etc. The man at ALT used to work at Startrite and seems to know a lot about these machines - handy he is close to me.

I bought it miles away, described as MINT... and it definitely is NOT.

But mechanically / technically it is good and working very well now, after a tune-up:

Lower guides (Vee shape blocks) are same at upper so interchangable. I like the fact the lower assembly can be height adjusted, so once it is set, move the entire block up below the table, which is relieved around the blade aperture. I reckon the blade enters the lower guides maybe 5mm under the exit of the cut. Simple and very good indeed. (Here the lower yellow guard is dropped down for access.

Here are the upper guides - one half-inch spanner (supplied) does everything. And this one has the circle-cutter attached also.

The spanner does almost everything. I suspect they may go astray sometimes. I like the fact the cutting guide on rating plate lists bakelite, strawboard... and bone

The trunnion is robust but simple. Mine is missing the angle indicator... may find one at ALT but I never rely on them anyway

The safety switches (upper here) can cause issues, but mine are fine, and I suspect if the hinges and catches are well-adjusted all will be good.

The fence on mine is the steel slab version (I think some later had extruded ali fences?). It is an outstanding fence, rock solid. I have added a larger hardwood fence for deep ripping but that is removable. Pics of that later. The steel fence also has a depth stop (tenons etc) which is also rock solid and might be handy sometimes.

The table was an issue. It is in 2 halves and they didn't align correctly with a slight dip in left-hand around the centre. ALT advised me the trunnion mount is structural and shims are normally used to level the 2 halves. So feeler gauges and shim material, half an hour later it's good now. I used my Tsaw table and laid the 352 table face down, then shimmed and bolted everything up.

4" dust extract shute emerges deep inside the base cabinet, so I will fit some extension to save crawling under.

So it isn't mint, but it sure works very well. i have ripped veneers 8" plus with great success - I think that is a very demanding test of the machine, blade and setup, and I am happy with the outcome.

I'll get back with pics of fence etc, but generally very pleased. These 352s are widely respected, and deserve to be. Simple, rugged, very solid where they need to be, wheel balance excellent, blade tracks very true and stable with all the guides backed right away. Currently running a Tuffsaws 3/4 fastcut [112"] which I think is the perfect blade for precision ripping hardwoods on a machine this size.

Any other knowledge on these machines, please do add, and when I get to ALT I shall add more no doubt.

edit: some numbers for it:

1790 x 545 x 670 mm

355mm wheels

throat 350mm

height under guides approx 275mm

weight 118Kg

.75Kw motor (1Hp) - so far that has seemed plenty.

Max blade width 3/4", length 112"

I recently acquired a 352, and before I got it did some online research (though I probably missed some info) - couldn't find much in the way of an overall summary and 'review', so for the possible benefit of anyone thinking about getting one, I shall do one here. Maybe some questions for fellow-owners also.

Here's one - what does this do? It is not set as the bolt from top should presumably work on the cam below.

So, this one is serial 111314 (no date on plate). I plan a trip to A.L.T. Saws in Gillingham for a few little bits for it, the odd knob etc. The man at ALT used to work at Startrite and seems to know a lot about these machines - handy he is close to me.

I bought it miles away, described as MINT... and it definitely is NOT.

But mechanically / technically it is good and working very well now, after a tune-up:

Lower guides (Vee shape blocks) are same at upper so interchangable. I like the fact the lower assembly can be height adjusted, so once it is set, move the entire block up below the table, which is relieved around the blade aperture. I reckon the blade enters the lower guides maybe 5mm under the exit of the cut. Simple and very good indeed. (Here the lower yellow guard is dropped down for access.

Here are the upper guides - one half-inch spanner (supplied) does everything. And this one has the circle-cutter attached also.

The spanner does almost everything. I suspect they may go astray sometimes. I like the fact the cutting guide on rating plate lists bakelite, strawboard... and bone

The trunnion is robust but simple. Mine is missing the angle indicator... may find one at ALT but I never rely on them anyway

The safety switches (upper here) can cause issues, but mine are fine, and I suspect if the hinges and catches are well-adjusted all will be good.

The fence on mine is the steel slab version (I think some later had extruded ali fences?). It is an outstanding fence, rock solid. I have added a larger hardwood fence for deep ripping but that is removable. Pics of that later. The steel fence also has a depth stop (tenons etc) which is also rock solid and might be handy sometimes.

The table was an issue. It is in 2 halves and they didn't align correctly with a slight dip in left-hand around the centre. ALT advised me the trunnion mount is structural and shims are normally used to level the 2 halves. So feeler gauges and shim material, half an hour later it's good now. I used my Tsaw table and laid the 352 table face down, then shimmed and bolted everything up.

4" dust extract shute emerges deep inside the base cabinet, so I will fit some extension to save crawling under.

So it isn't mint, but it sure works very well. i have ripped veneers 8" plus with great success - I think that is a very demanding test of the machine, blade and setup, and I am happy with the outcome.

I'll get back with pics of fence etc, but generally very pleased. These 352s are widely respected, and deserve to be. Simple, rugged, very solid where they need to be, wheel balance excellent, blade tracks very true and stable with all the guides backed right away. Currently running a Tuffsaws 3/4 fastcut [112"] which I think is the perfect blade for precision ripping hardwoods on a machine this size.

Any other knowledge on these machines, please do add, and when I get to ALT I shall add more no doubt.

edit: some numbers for it:

1790 x 545 x 670 mm

355mm wheels

throat 350mm

height under guides approx 275mm

weight 118Kg

.75Kw motor (1Hp) - so far that has seemed plenty.

Max blade width 3/4", length 112"