Jacob

What goes around comes around.

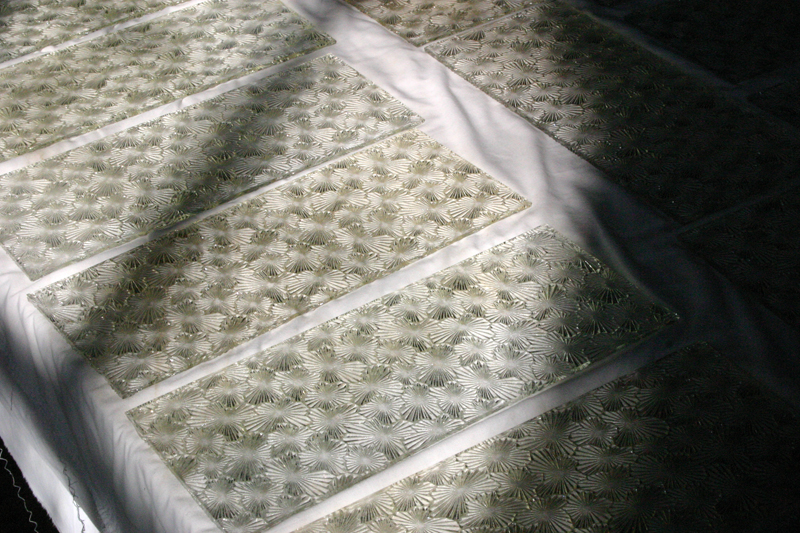

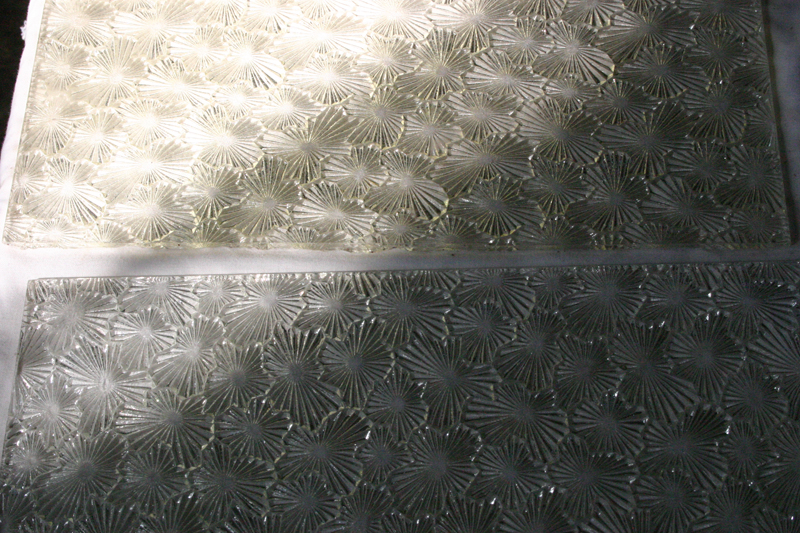

This way for a BIG WINDOW show - edited - this was a link to a now (nearly) defunct forum.

CHJ":29h5m0m8 said:Fingers crossed for the lifting in place, are you comissioned to do any internal refurbishing once the building is wind and weather proof ?

Tom K":13vn4bq3 said:CHJ":13vn4bq3 said:..... are you comissioned to do any internal refurbishing once the building is wind and weather proof ?

I believe that is Jacobs very own chapel. So yeah :lol: Nice ride Mr G

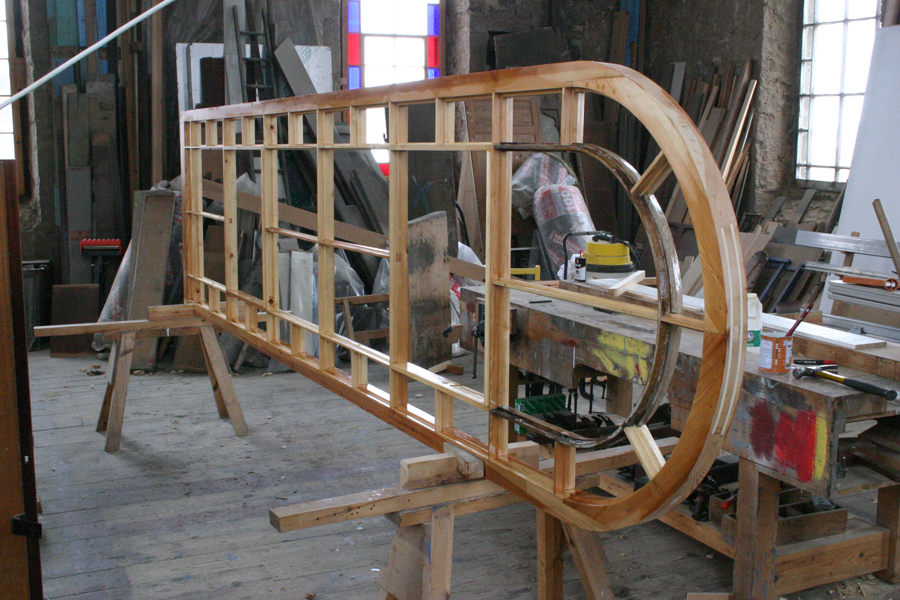

I've got to finish it to make making a living a lot easier - very difficult at the moment. I'll end up with a 1000 sq ft workshop in the basement, all dry, well lit and warm, and living space in the chapel above, with display space for furniture etc.CHJ":2kmpc3ee said:Tom K":2kmpc3ee said:CHJ":2kmpc3ee said:..... are you comissioned to do any internal refurbishing once the building is wind and weather proof ?

I believe that is Jacobs very own chapel. So yeah :lol: Nice ride Mr G

Ahh, should have taken the time to go back and check the history behind the thread.

No excuses really for not seeing the rest of the place refurbished to 'old craftsman picture book' standard then.

Who needs the time to make a living.

Steve Maskery":1o3dbyq8 said:I'd have to take out the old wooden windows and install UPVC.

Zimmer? Or Range Rover?Jacob":2tm6lr5p said:That's my current mode of transport on the right, not for much longer.