I recently blew some savings on a TS-200 from Axminster, just before the prices went up (largely because I had been watching it for a while, and from past eBay auctions I figured I'd be able to sell it on at not much of a loss if I wasn't happy with it). I knew it wasn't going to be perfect, and I'm willing to mess around with it to get it running well. I've used it for basic rips and crosscuts and I'm very happy with it on the whole, I still have all my fingers and there are no dents in the garage door behind it, so I'm getting caught up in the moment!

I knew from the outset that I would have trouble finding aftermarket accessories to fit the nonstandard mitre slot - but I happened across the Milescraft featherboard at a decent price, and since it advertised a 5/8" mitre runner on the packaging, I thought I'd give it a go. In case there's anyone else out there with a TS-200 and a desperate desire to buy a third-party featherboard, it fit fine after a couple of minutes' sanding down the aluminium runner (and filing down a bit of burr on the edge of the mitre slot on the table). It locks nice and securely, and adjusts back and forth.

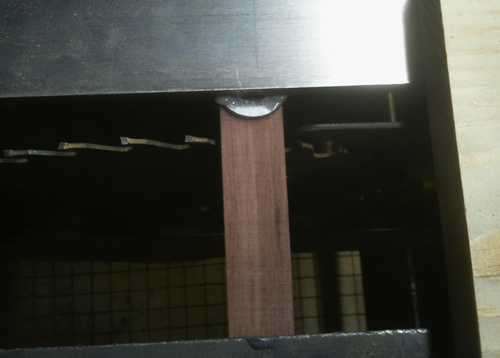

But that's not why I'm posting - see, the next thing I thought I'd do was make a zero-clearance insert, following along with one of Steve M's DVDs; it seemed like a good idea, not least since I've already seen a few smaller offcut bits drop into the table and rattle around something rotten between the blade and the crown guard and the internal blade guard before getting spat out at the bottom in several pieces. I've found a piece of smooth-faced hardboard the exact thickness necessary to sit flush on the little ledge that supports the supplied aluminium insert, I've discovered the radius to cut the corners (3/4") and fashioned a piece (well, three pieces, actually) which sits perfectly in the hole in the table... but as can be seen from the below picture, there's a small problem in the support department:

The ledge actually only runs about half-way around the hole, and there's nothing to support the insert on the left-hand side (top of photo). Since I expect a not-inconsiderable amount of force to be exerted downwards on this thing, at least at the front, I'm a bit worried that it may be pulled down, flipped sideways into the hole and disappear forever! With the blade fully retracted here, the insert would fairly easily tip into the gap on the left with only a little more pressure than it took to pop it into place in the first place.

Now, I've checked out the extents of the blade's and the riving knife's travel and I'm pretty sure that there's a good centimetre at the front and back which will never be intruded upon - at least not with this size blade - but I'm unsure as to how to go about attaching something to support the insert. My first thought is to get the epoxy glue out and just glue a washer or something to the underside of the table, poking out into the gap a little to provide a small ledge, but I'm not convinced it'll be especially strong. I'm not emotionally prepared (yet!) to go drilling into the table if I can possibly avoid it, or I'd just tap a hole and attach said washer with a cut-down machine screw... does anyone have any other advice? Or am I worrying about nothing, and if I screw the insert down into the provided screwholes I'll never have a problem anyway?

(I'm also wondering as a future project about fashioning a less-protruding riving knife; I gather from past threads on the subject that the important things are "tool steel", a thickness somewhere between the thickness of the blade's body and the thickness of the teeth, and mounting it with a closed slot so it doesn't fly off and stab me in the face, but if anyone has any other advice I'm all ears! Can one cut ~2mm tool steel with a hacksaw, or is that going to be messy enough it wouldn't make a good knife?)

I knew from the outset that I would have trouble finding aftermarket accessories to fit the nonstandard mitre slot - but I happened across the Milescraft featherboard at a decent price, and since it advertised a 5/8" mitre runner on the packaging, I thought I'd give it a go. In case there's anyone else out there with a TS-200 and a desperate desire to buy a third-party featherboard, it fit fine after a couple of minutes' sanding down the aluminium runner (and filing down a bit of burr on the edge of the mitre slot on the table). It locks nice and securely, and adjusts back and forth.

But that's not why I'm posting - see, the next thing I thought I'd do was make a zero-clearance insert, following along with one of Steve M's DVDs; it seemed like a good idea, not least since I've already seen a few smaller offcut bits drop into the table and rattle around something rotten between the blade and the crown guard and the internal blade guard before getting spat out at the bottom in several pieces. I've found a piece of smooth-faced hardboard the exact thickness necessary to sit flush on the little ledge that supports the supplied aluminium insert, I've discovered the radius to cut the corners (3/4") and fashioned a piece (well, three pieces, actually) which sits perfectly in the hole in the table... but as can be seen from the below picture, there's a small problem in the support department:

The ledge actually only runs about half-way around the hole, and there's nothing to support the insert on the left-hand side (top of photo). Since I expect a not-inconsiderable amount of force to be exerted downwards on this thing, at least at the front, I'm a bit worried that it may be pulled down, flipped sideways into the hole and disappear forever! With the blade fully retracted here, the insert would fairly easily tip into the gap on the left with only a little more pressure than it took to pop it into place in the first place.

Now, I've checked out the extents of the blade's and the riving knife's travel and I'm pretty sure that there's a good centimetre at the front and back which will never be intruded upon - at least not with this size blade - but I'm unsure as to how to go about attaching something to support the insert. My first thought is to get the epoxy glue out and just glue a washer or something to the underside of the table, poking out into the gap a little to provide a small ledge, but I'm not convinced it'll be especially strong. I'm not emotionally prepared (yet!) to go drilling into the table if I can possibly avoid it, or I'd just tap a hole and attach said washer with a cut-down machine screw... does anyone have any other advice? Or am I worrying about nothing, and if I screw the insert down into the provided screwholes I'll never have a problem anyway?

(I'm also wondering as a future project about fashioning a less-protruding riving knife; I gather from past threads on the subject that the important things are "tool steel", a thickness somewhere between the thickness of the blade's body and the thickness of the teeth, and mounting it with a closed slot so it doesn't fly off and stab me in the face, but if anyone has any other advice I'm all ears! Can one cut ~2mm tool steel with a hacksaw, or is that going to be messy enough it wouldn't make a good knife?)