Derek Cohen (Perth Oz)

Established Member

This should make a change from discussing sharpening :lol:

Hang about, I did have to sharpen a few chisels and spokeshaves. What is the best method ..... (hammer)

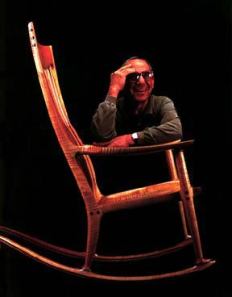

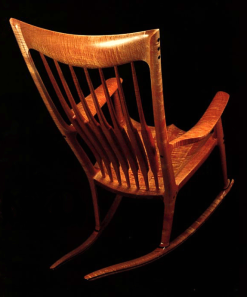

Well, I have finally begun building The Chair. There is an introduction to the project which, with the exception of a little lathe work and roughing out on the bandsaw, has a hand tool focus ..

http://www.inthewoodshop.com/Furniture/ ... ction.html

I have been busy the part week ... well, a few hours each day (as I am on leave) ..

Building the legs: http://www.inthewoodshop.com/Furniture/ ... eLegs.html

Templates: http://www.inthewoodshop.com/Furniture/ ... lates.html

Stretchers: http://www.inthewoodshop.com/Furniture/ ... chers.html

Tenons: http://www.inthewoodshop.com/Furniture/ ... enons.html

Morticing: http://www.inthewoodshop.com/Furniture/ ... tices.html

As always, any advice and discussion is welcomed.

Best wishes from Perth for the New Year

Derek

Hang about, I did have to sharpen a few chisels and spokeshaves. What is the best method ..... (hammer)

Well, I have finally begun building The Chair. There is an introduction to the project which, with the exception of a little lathe work and roughing out on the bandsaw, has a hand tool focus ..

http://www.inthewoodshop.com/Furniture/ ... ction.html

I have been busy the part week ... well, a few hours each day (as I am on leave) ..

Building the legs: http://www.inthewoodshop.com/Furniture/ ... eLegs.html

Templates: http://www.inthewoodshop.com/Furniture/ ... lates.html

Stretchers: http://www.inthewoodshop.com/Furniture/ ... chers.html

Tenons: http://www.inthewoodshop.com/Furniture/ ... enons.html

Morticing: http://www.inthewoodshop.com/Furniture/ ... tices.html

As always, any advice and discussion is welcomed.

Best wishes from Perth for the New Year

Derek