i feel like you have mentioned previously but is your door already ordered?/ a set dimension? there is not much timber around it and i feel your whole wall is going to shake when you close the door, I would certainly look to beef up the surrounding even just extra noggins either side if your have no more timber would be a start.

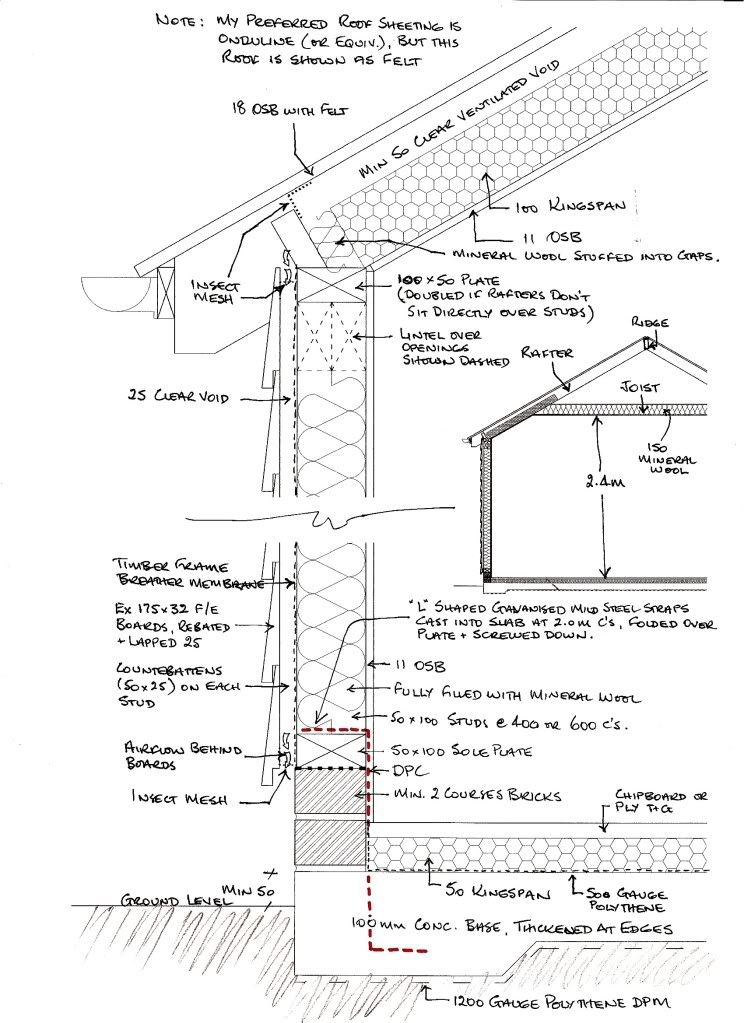

Regarding DPM DPC situation, I am no expert, I am a carpenter so I'm sure many others can weigh in with more expertise on the matter but here is my take, the dpc ontop of your brick course is merely to prevent water passing up through the masonry into the plate of your wall, the dpm is to keep all moisture outside of the inhabited space, you need it to run continously above anywhere moisture will be present ie masonry and below anything inside your finished space, at this point the best you can do is lay it ontop of your slab and lap it up the brick, here is where someone else needs to weigh in as in my opinion this is the crucial point, i think the dpc should be turned down and the dpm lapped over it with radbar tape sealing the joint between them, if dpc goes over dpm i feel theres a chance for rising moisture in the bricks to run across the underside of the dpc over the dpm and into your workshop.

At this point its a pain in the arse but not impossible to lift the walls as they are and get you DPM to run under the plates to create a continuous seal.

if none of this sound appealing at this point do the following, take battens, can be cheap 2x1 roof battens if your budget is tight, run them down your studs outside trapping your excess dpc down over the bricks and extending the lowest point of your cladding over the bricks to hopefully keep them from getting wet, you need to have a clearance of 150mm below your cladding so you will probably need to excavate a little around the base of your workshop to get some extra height. i know when money is tight extra spending seems impossible but getting the structure and outer skin of this build correct is key the rest can be done when you can and is easier to upgrade later down the road. if i were you, at this stage i would really consider giving a decent overhang all the way around your building, the size of a roofs overhang and the maintenance required for a building like this are directly proportional - more overhang = less maintenance, not to mention keeping the immediate ground around your workshop dry.

I hope all this doesn't sound like I'm having a go, it all comes from a good place but you are a stage where some things can and should be corrected to save potential issues down the road when if cost a lot and hurts a lot more to correct any issues.