sploo

Somewhat extinguished member

After preparing the stock for my inside out Xmas ornament (an-inside-out-xmas-ornament-t102181.html) I had some of the diamond shaped pieces left, so decided to use them to make some (admittedly fairly small) coasters.

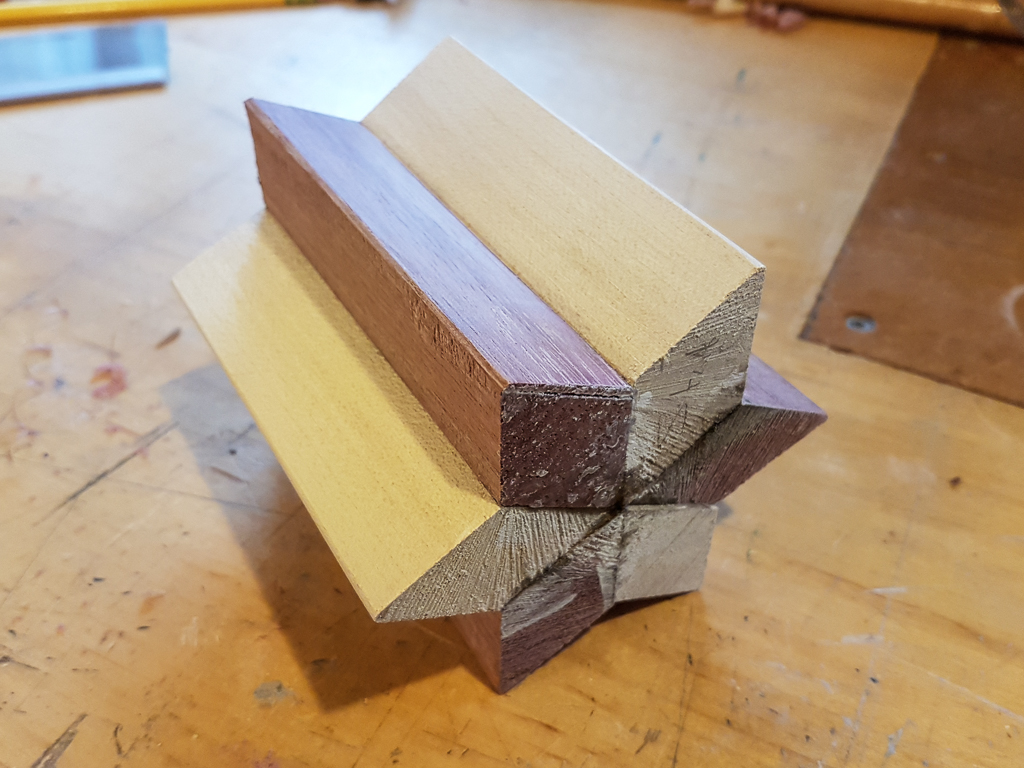

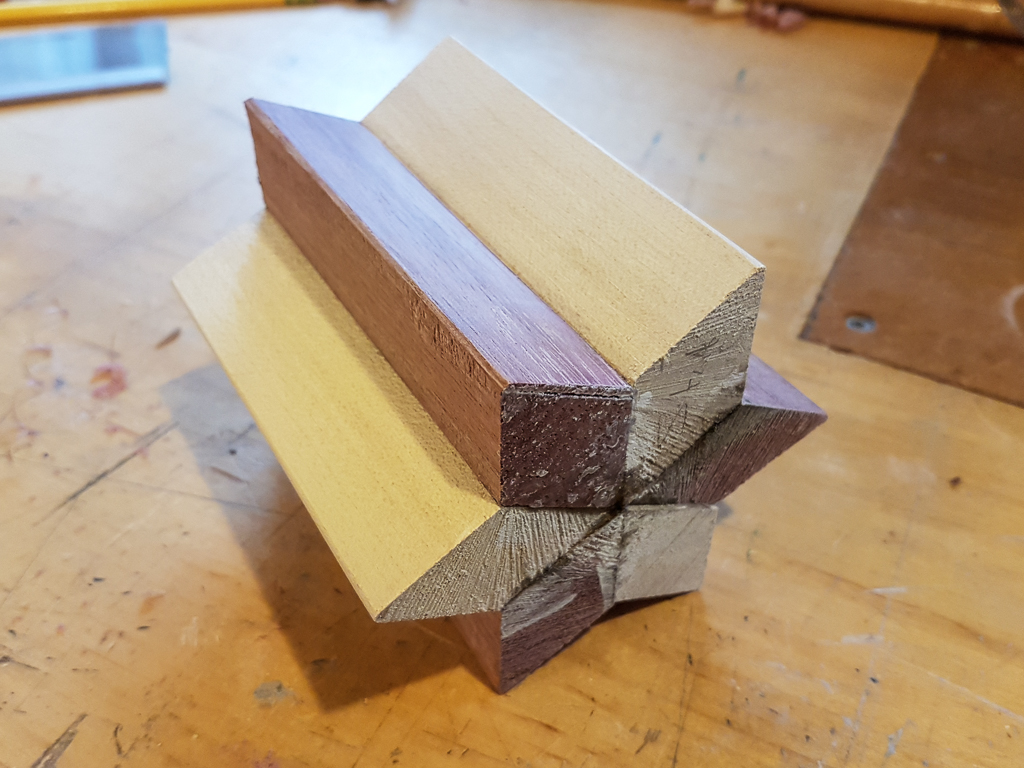

I did a better job of joining the two halves (of three diamonds), so no nasty gaps this time:

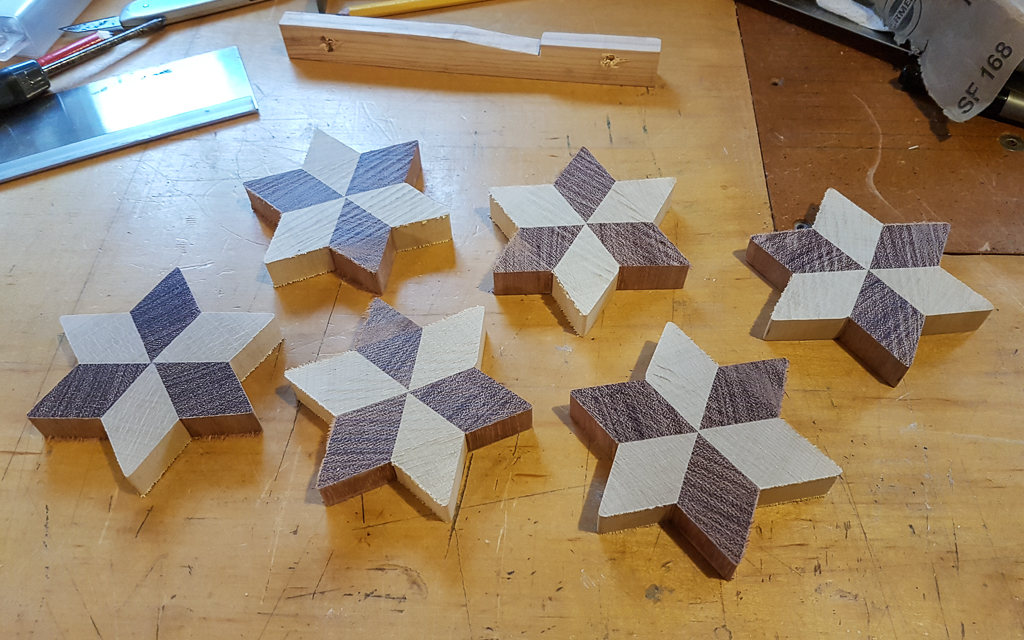

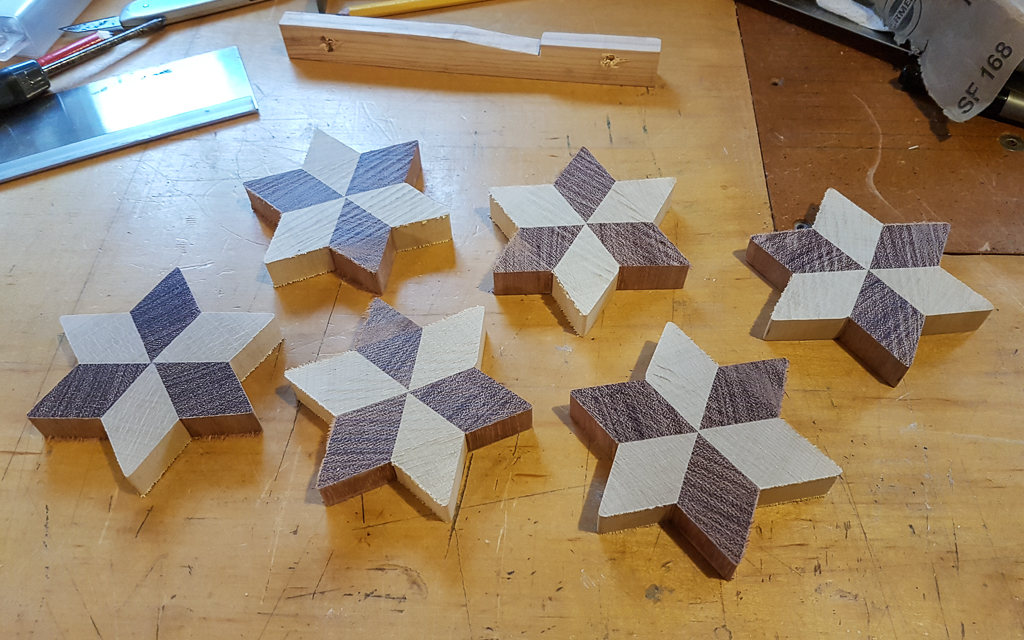

They are too big for my table saw, so I sliced them up using the bandsaw:

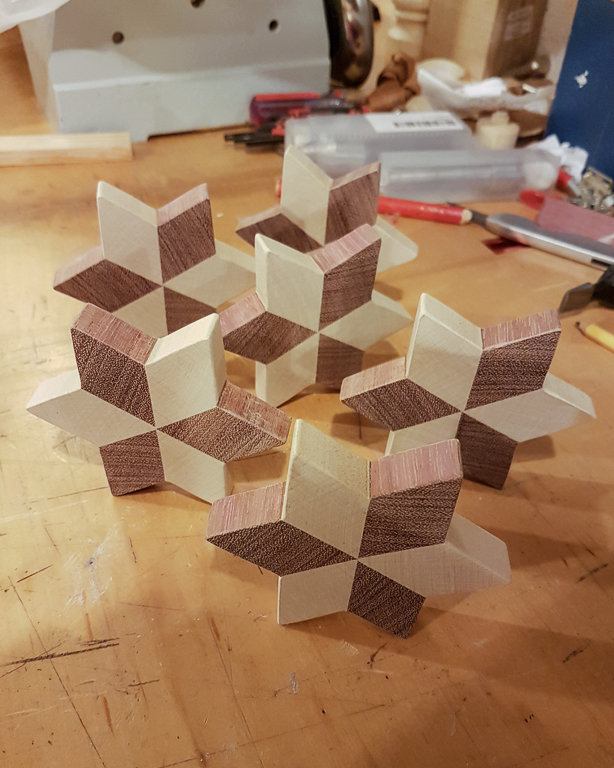

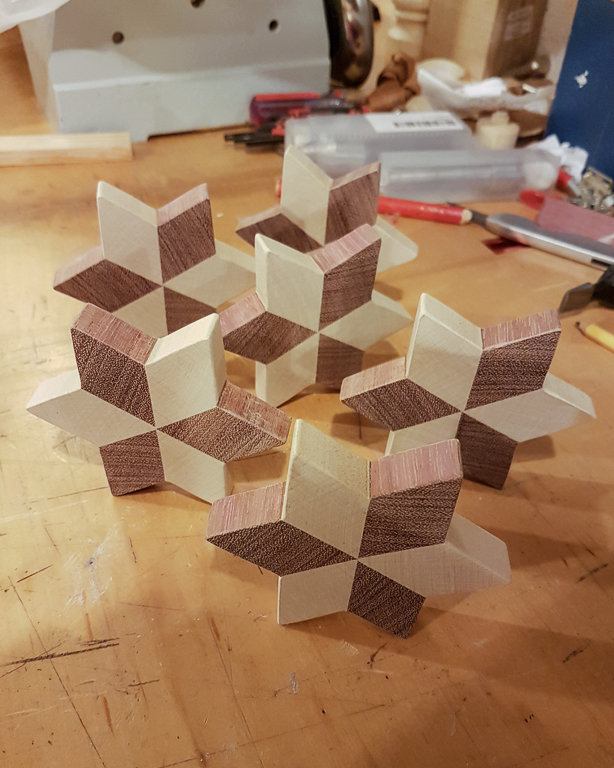

I don't have a drum sander, so it was a combination of my disc sander and then finer grits on a flat surface:

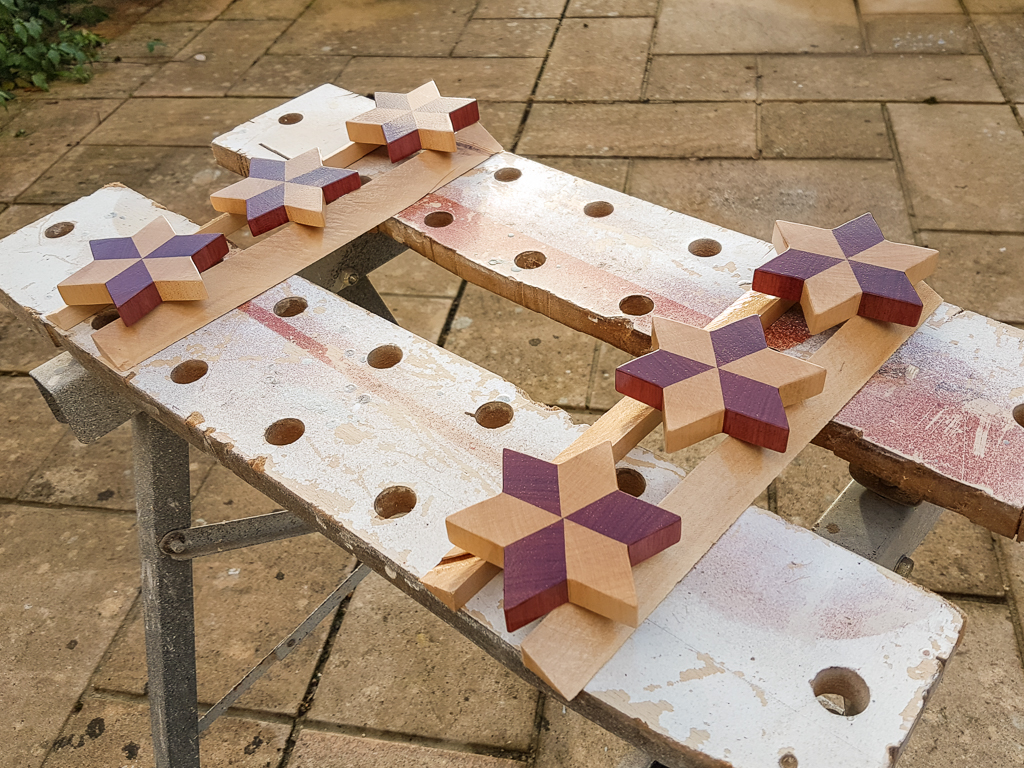

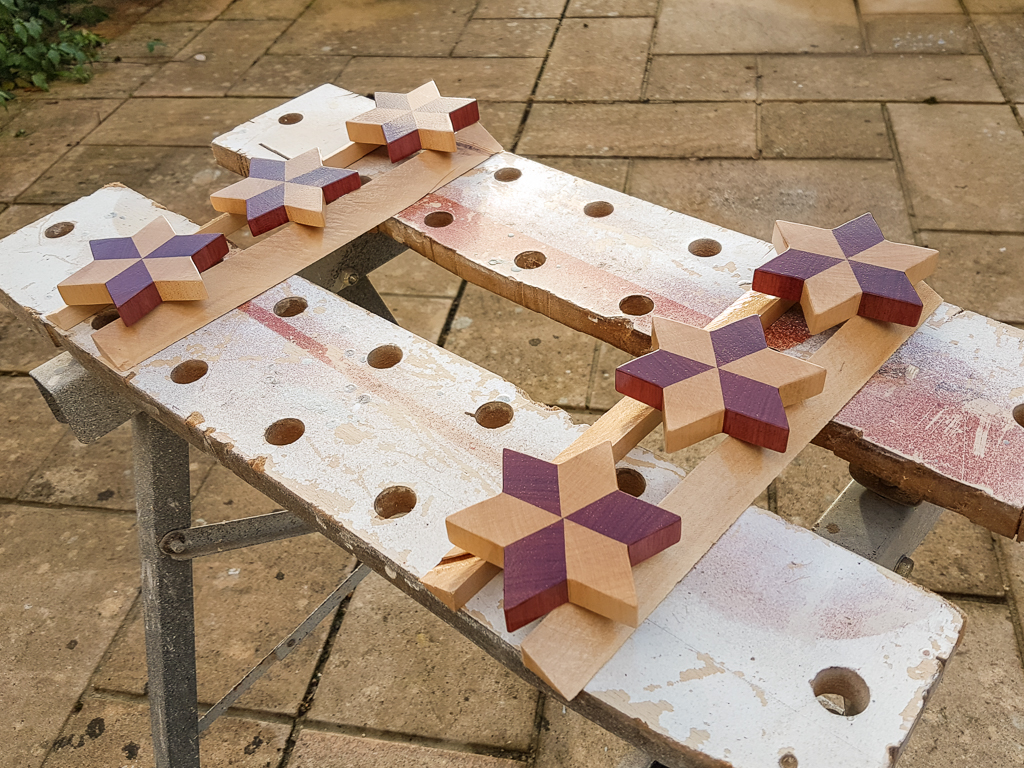

I then gave them a coat of Danish oil, left them for over a week, and applied a few coats of acrylic clear lacquer (Halfords brand):

Finally, I left them for another couple of weeks and gave them a light sand with 600 then 1000 grit wet and dry, and then another couple of coats of the lacquer (no photos of that, but they ended up silky smooth).

I did a better job of joining the two halves (of three diamonds), so no nasty gaps this time:

They are too big for my table saw, so I sliced them up using the bandsaw:

I don't have a drum sander, so it was a combination of my disc sander and then finer grits on a flat surface:

I then gave them a coat of Danish oil, left them for over a week, and applied a few coats of acrylic clear lacquer (Halfords brand):

Finally, I left them for another couple of weeks and gave them a light sand with 600 then 1000 grit wet and dry, and then another couple of coats of the lacquer (no photos of that, but they ended up silky smooth).