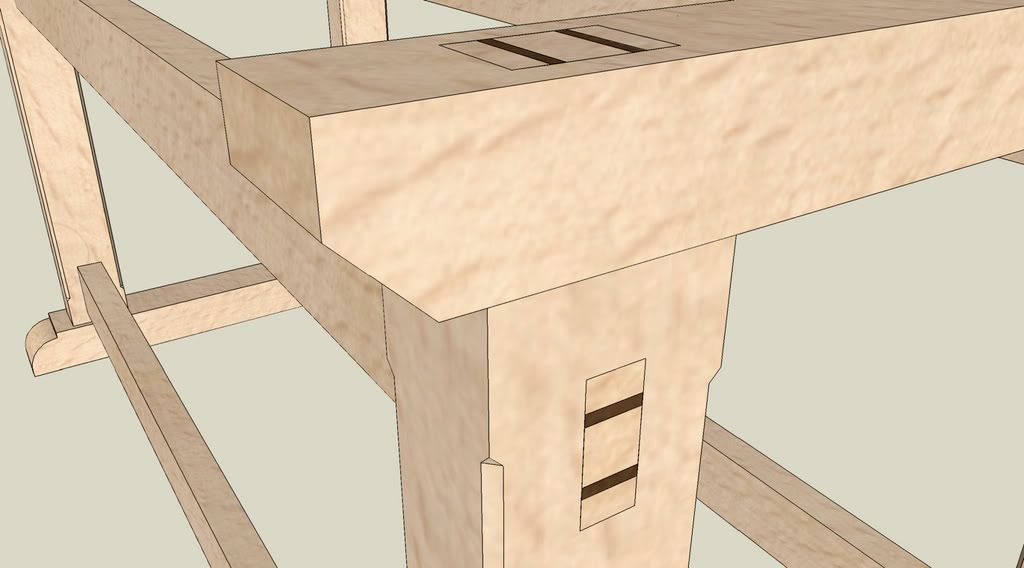

Oh don't get me wrong, I think a single tenon is fine in such a situation (OK that's not quite what I said above, I'll admit), and I bet mine is just a single. I just think it is a bit fat for the section, that's all.

My thinking has been coloured by the fact that I originally thought I was seeing end-grain of twin tenons, whereas it is actually the wedges I was looking at.

OK, moving on, I'd make the long rails knock-down, like a bed, otherwise that looks as if it's going to be one big mother to move.

Also, consider EXACTLY where your vice is going to go. I didn't do that calculation accurately enough on my bench, and it fouls the frame a bit. When you come to add the top, either make the top overhang the end enough to accommodate the vice with clearance (a base like that should be able to support a cantilevered vice without much problem, I'd have thought), or keep the frame far enough towards the end of the top to allow the movement of the vice on the inside of the frame. My preference would be for the former.