oddsocks

Established Member

This was going to be a WIP post but issues with my flickr photo account meant i've now completed it .....plenty of pictures!

Some years ago I built a round table in oak but this has gone black despite treatments. My wife also wanted a rectangular table (I walked into that one when I asked where the table had gone and why were the chairs spaced in a rectangle on the decking).

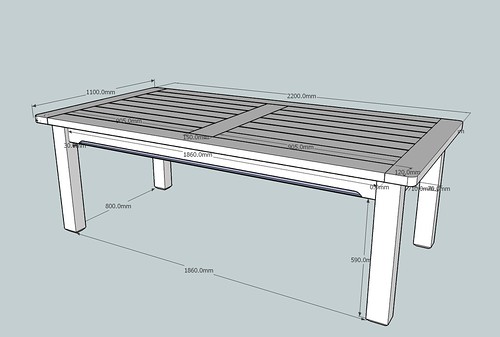

The brief was to seat 8 without them hitting the legs, so this sketchup...

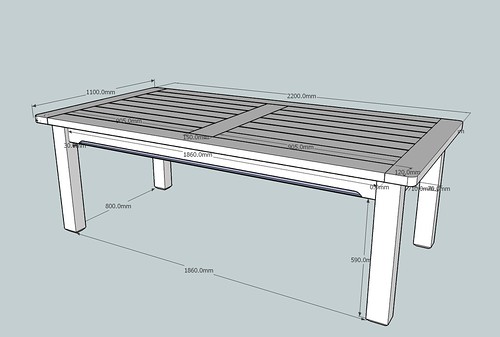

became this table after 7 days of work....

The number of slats increased from 7 to 8 based on appearance during the dry fit. Also an error on my part meant the length of the top became 2.1m not 2.2m (the leg frame stayed as intended).

Now for the build....

I sourced the timber from Thorogoods in Ardleigh nr Colchester at £45 p cu ft, total was £330 with VAT. I know SLhardwoods etc are showing £35 per cu ft, but Thorogoods were convenient and put out the 3 pallets of 4", 1" and 1.5" in their selection area for me to sort through, and the timber was excellent.

I had to buy the full boards so it was fun working out how to get most of it from a 4m x 260mm x 100mm single board (£200 + VAT ouch!) and then cut it to fit into the A6 estate. As well as the 4" board I also needed 2 boards at 4m x 260mm x 1" for the slats. Here's the boards as taken to the car (my ryobi oneplus alligator saw did the cutting at the timber yard)

marked up...

and cut on the bandsaw (record BAS350 with dragon sw M42 blade that was not new) - the use of rollers was essential to support the weight. By the end of all the resawing the blade was finally beginning to struggle -but I have used it for a year.

Ryobi in use again

and the final stack 4 hours later waiting to be planned and jointed etc. The slats are in the vertical

Work calls, so i'll post more images later

EDIT - timeline and WIP pics at the end of page 1

Some years ago I built a round table in oak but this has gone black despite treatments. My wife also wanted a rectangular table (I walked into that one when I asked where the table had gone and why were the chairs spaced in a rectangle on the decking).

The brief was to seat 8 without them hitting the legs, so this sketchup...

became this table after 7 days of work....

The number of slats increased from 7 to 8 based on appearance during the dry fit. Also an error on my part meant the length of the top became 2.1m not 2.2m (the leg frame stayed as intended).

Now for the build....

I sourced the timber from Thorogoods in Ardleigh nr Colchester at £45 p cu ft, total was £330 with VAT. I know SLhardwoods etc are showing £35 per cu ft, but Thorogoods were convenient and put out the 3 pallets of 4", 1" and 1.5" in their selection area for me to sort through, and the timber was excellent.

I had to buy the full boards so it was fun working out how to get most of it from a 4m x 260mm x 100mm single board (£200 + VAT ouch!) and then cut it to fit into the A6 estate. As well as the 4" board I also needed 2 boards at 4m x 260mm x 1" for the slats. Here's the boards as taken to the car (my ryobi oneplus alligator saw did the cutting at the timber yard)

marked up...

and cut on the bandsaw (record BAS350 with dragon sw M42 blade that was not new) - the use of rollers was essential to support the weight. By the end of all the resawing the blade was finally beginning to struggle -but I have used it for a year.

Ryobi in use again

and the final stack 4 hours later waiting to be planned and jointed etc. The slats are in the vertical

Work calls, so i'll post more images later

EDIT - timeline and WIP pics at the end of page 1