MikeG.

Established Member

This is so quick and simple that there isn't much I could show in terms of a WIP. I glued some cross grain parana pine to a strip of long-grain parana pine, then planed it all down to a reasonable shape, and the long grain element to as thin as I dared. I took it in to the house, and this is what happened to it over an hour or so:

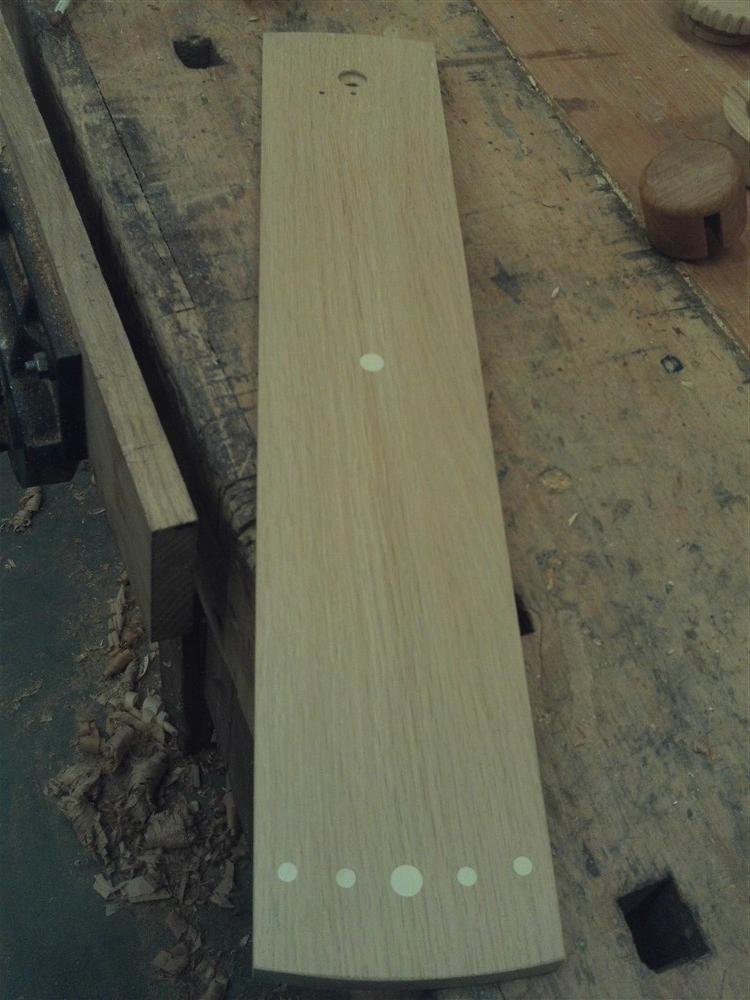

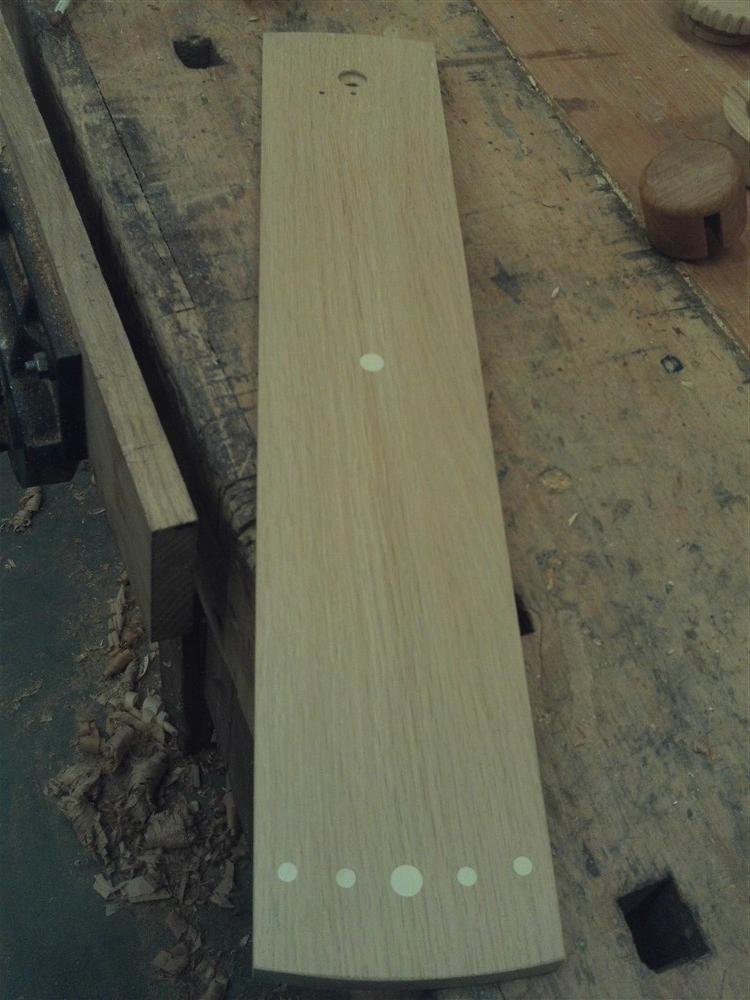

This was intended as a proof-of-concept model, but it worked so well that I decided to put it on a backing board. I found an off-cut of oak, shaped it quickly, and drilled out some holes to fill them with 2 part filler:

A few minutes with a bandsaw and belt sander, and I had a suitable mounting block for the indicator arm thingy, and after finishing everything with Osmo PolyX (I've got to try to use the stuff up), and some wax, I glued up:

My wife thinks it's ugly, and it doesn't actually serve a purpose in the house, so I'll hang it on a wall in the workshop. If nothing else it will be a visual reminder of how much wood moves with humidity (it's been to its full extent the other way......at the moment it is showing "dry").

If any of you have 90 minutes to spare, have a go at one of these. It's better use of time than sitting watching football.

This was intended as a proof-of-concept model, but it worked so well that I decided to put it on a backing board. I found an off-cut of oak, shaped it quickly, and drilled out some holes to fill them with 2 part filler:

A few minutes with a bandsaw and belt sander, and I had a suitable mounting block for the indicator arm thingy, and after finishing everything with Osmo PolyX (I've got to try to use the stuff up), and some wax, I glued up:

My wife thinks it's ugly, and it doesn't actually serve a purpose in the house, so I'll hang it on a wall in the workshop. If nothing else it will be a visual reminder of how much wood moves with humidity (it's been to its full extent the other way......at the moment it is showing "dry").

If any of you have 90 minutes to spare, have a go at one of these. It's better use of time than sitting watching football.