MikeG.

Established Member

A fun little diversion, now. We needed some curtain poles in the lounge, and decided that oak and wrought iron was the look we were going for. My wife obviously was confident that running up some wooden curtain poles wouldn't be too difficult....

I made a jig. I wanted lots of depth to the jig, but my forstner bits are only so long. I therefore made it in 2 pieces:

The idea is to get down to 32mm diameter in two passes, one at 35mm and the next at 32mm. Learning from the proof-of-principle model I made for the dowels for the satirs, I made a very secure slot for the chisel to eliminate any movement other than the in-out adjustment. Time for a test piece:

The funny little connector thingy on the bench is a screw on one end and a bolt/ threaded rod on the other, and that will be what screws into the end of the dowel.

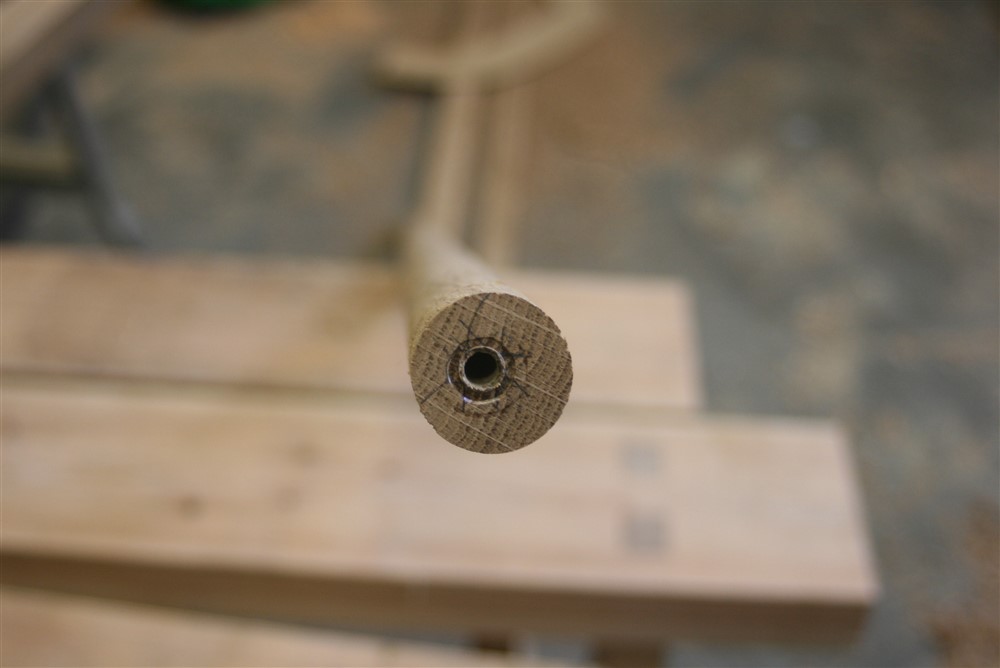

This produced a really decent result first time, but it also shook like hell and produced a real oddity:

How did it end up turning massively off-centre?

On to the real thing. There are three curtain poles to do, two at 1.7m, and one at 2.4m. I straightened up and ripped a nice piece of oak from my stores, and then chamfered the edges to produce an octogon:

Then shaped the end:

........attached the drill and got on with it:

The result was lovely!

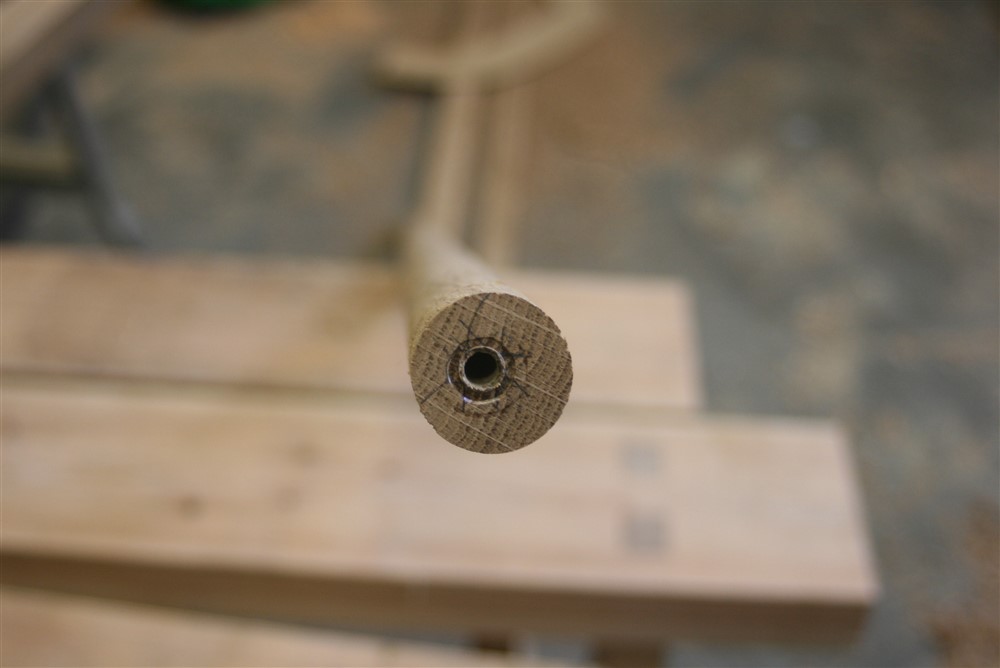

But again, the oddity of an off-centre feed. It started off bang in the middle of the octogon:

The other shorter pole is prepared and ready to turn in the morning, just waiting for the glue in a shake to dry. The longer pole was longer than any wood I could find of the right size, but I did find some 12mm thick off cuts. I cleaned them up, ripped them, and will laminate them together in the morning:

I made a jig. I wanted lots of depth to the jig, but my forstner bits are only so long. I therefore made it in 2 pieces:

The idea is to get down to 32mm diameter in two passes, one at 35mm and the next at 32mm. Learning from the proof-of-principle model I made for the dowels for the satirs, I made a very secure slot for the chisel to eliminate any movement other than the in-out adjustment. Time for a test piece:

The funny little connector thingy on the bench is a screw on one end and a bolt/ threaded rod on the other, and that will be what screws into the end of the dowel.

This produced a really decent result first time, but it also shook like hell and produced a real oddity:

How did it end up turning massively off-centre?

On to the real thing. There are three curtain poles to do, two at 1.7m, and one at 2.4m. I straightened up and ripped a nice piece of oak from my stores, and then chamfered the edges to produce an octogon:

Then shaped the end:

........attached the drill and got on with it:

The result was lovely!

But again, the oddity of an off-centre feed. It started off bang in the middle of the octogon:

The other shorter pole is prepared and ready to turn in the morning, just waiting for the glue in a shake to dry. The longer pole was longer than any wood I could find of the right size, but I did find some 12mm thick off cuts. I cleaned them up, ripped them, and will laminate them together in the morning: