oddsocks

Established Member

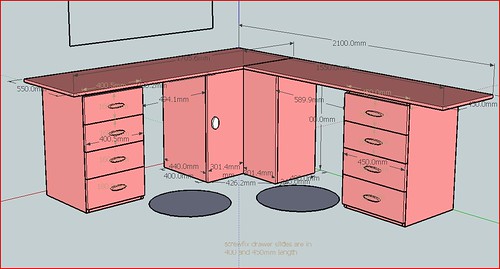

I have been asked by a neighbour to make (using MR MDF) a childrens' desk /corner/drawer unit arrangement and paint it using dulux eggshell. It's a large project to paint by hand and I want to get the best finish so am considering adding a better paint sprayer to my compressor airtools collection (I currently only have the very cheap fence panel type spray gun).

I've searched the various threads but haven't found the answer to my questions (but found lots of other useful info around the topic!).

Can anyone help me answer the following or give at least some guidance. I've got a sealey frame compressor, 2HP with a free air delivery of 5.2cfm. so am somewhat limited, and really want to spend in the £30 - £60 range on a gun.

Given that its MR MDF and I'll follow other threads guidance on primer coats (using dulux probably) denibbing and top coats (dulux eggshell)....

The trigger is this project but I will no doubt use it in the future so need to balance the one off cost v capability.

thanks

Dave

I've searched the various threads but haven't found the answer to my questions (but found lots of other useful info around the topic!).

Can anyone help me answer the following or give at least some guidance. I've got a sealey frame compressor, 2HP with a free air delivery of 5.2cfm. so am somewhat limited, and really want to spend in the £30 - £60 range on a gun.

Given that its MR MDF and I'll follow other threads guidance on primer coats (using dulux probably) denibbing and top coats (dulux eggshell)....

- What spray nozzle size is recommended for the dulux paints (looking at the sealey range as an example guns are supplied with 1.2- 2.2mm at least)?

Can the same nozzle be used for both the primer and top coat?

Gravity feed or suction cup for the gun?

Any recommended products (given my 2HP and 5.2cfm FAD)

Would I be better off spending the same money on a cheaper electric system such as earlex?

The trigger is this project but I will no doubt use it in the future so need to balance the one off cost v capability.

thanks

Dave