Droogs

Not the Sharpest Moderator in the box

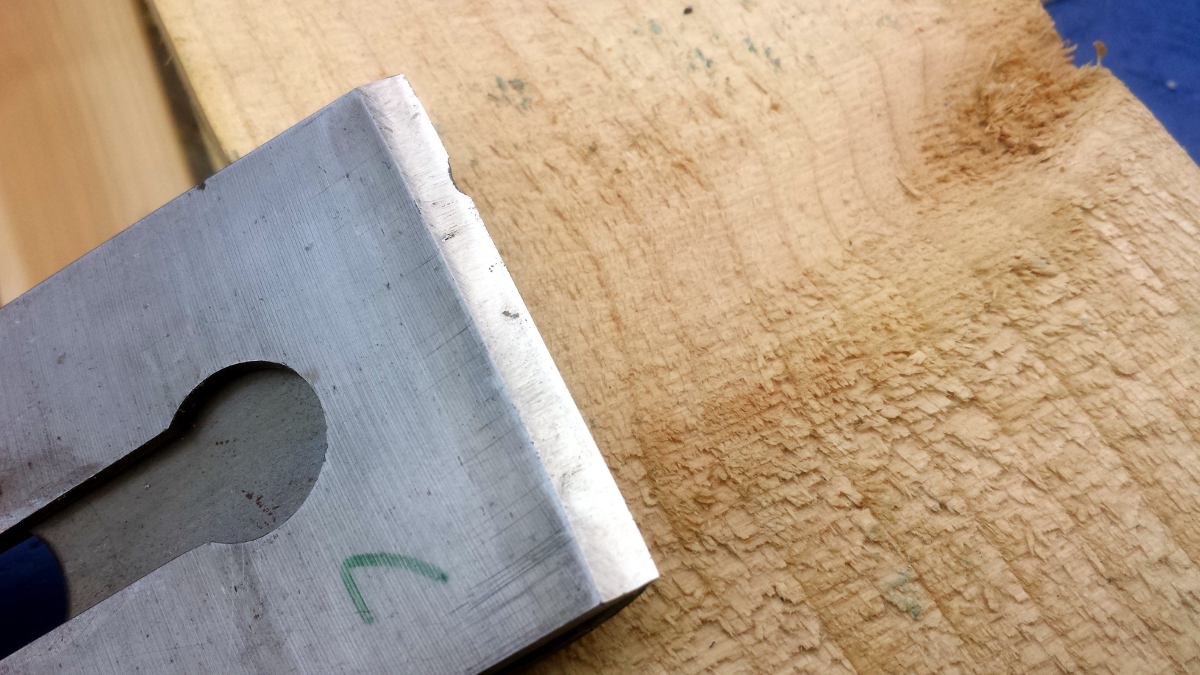

Finished up today, but built over the last week fom rough board and built using hand tools only apart from some pilot holes made with a drill/driver. Maple laminated top with Redwood base and sacraficial lipping. 2000mm x 610mm and 39" high. 151 face vice with a 52 1/2 tail vice. Split top with an oak insert to act as a stop when planning alon with 20 19mm bench dog holes (not fun to do), just a shelf to fit on the bottom but no rush as rock solid and still need to paint the workshop